Abstract

The study of functional and dyeing properties of the electrospun nanofibers has recently gained substantial interest. However, the dyeing of nanofibers still in transition phase and faces problem of lower color yield. Owing to the higher surface area of cellulose nanofibers, the color yield obtained is nearly four to five times lower than the conventional cotton fiber. The present work reports on dyeing of cellulose nanofibers with CI reactive black 5 dye via a simple and dual padding method to improve color yield and dye fixation. The color yields were determined by K/S values and color coordinates using spectrophotometer and the results were compered between single and dual padding methods. The dyed cellulose nanofibers were characterized by FTIR, WAXD and FE-SEM. X-ray diffraction studies revealed that the dyed cellulose nanofibers having Cellulose II form and show a better crystallinity than the undyed cellulose nanofibers.

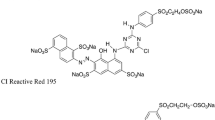

Graphical abstract

Similar content being viewed by others

References

Bai G, Song XY (2005) Dyeing properties of polyamide super-microfibre with disperse dyes. Color Technol 121:329–331

Chung C, Lee M, Choe EK (2004) Characterization of cotton fabric scouring by FT-IR ATR spectroscopy. Carbohydr Polym 58:417–420

de Morais Teixeira E, Corrêa AC, Manzoli A, de Lima Leite F, de Oliveira CR, Mattoso LHC (2010) Cellulose nanofibers from white and naturally colored cotton fibers. Cellulose 17:595–606

Ding B, Li C, Hotta Y, Kim J, Kuwaki O, Shiratori S (2006) Conversion of an electrospun nanofibrous cellulose acetate mat from a super-hydrophilic to super-hydrophobic surface. Nanotechnol 17:4332–4339

Ford ENJ, Mendon SK, Thames SF, Rawlins JW (2010) X-ray diffraction of cotton treated with neutralized vegetable oil-based macromolecular crosslinkers. J Eng Fiber Fabr 5:10–20

Goswami P, Blackburn RS, Taylor J, White P (2009) Dyeing behaviour of lyocell fabric: effect of NaOH pre-treatment. Cellulose 16:481–489

Goswami P, Blackburn RS, Taylor J, White P (2011) Sorption of dyes on cellulose II: effect of alkali treatment of fibre and dye structure. Cellulose 18:1063–1072

Greiner A, Wendorff JH (2007) Electrospinning: a fascinating method for the preparation of ultrathin fibers. Angew Chem Int Edit 46:5670–5703

Han XJ, Huang ZM, He CL, Liu L, Wu QS (2008) Coaxial electrospinning of PC (shell)/PU (core) composite nanofibers for textile application. Polym Comp 29:579–584

Huang L, Nagapudi K, Apkarian RP, Chaikof EL (2001) Engineered collagen–PEO nanofibers and fabrics. J Biomater Sci-Polym E 12:979–993

Jonoobi M, Harun J, Mathew AP, Hussein MZB, Oksman K (2010) Preparation of cellulose nanofibers with hydrophobic surface characteristics. Cellulose 17:299–307

Jonoobi M, Khazaeian A, Tahir PM, Azry SS, Oksman K (2011) Characteristics of cellulose nanofibers isolated from rubberwood and empty fruit bunches of oil palm using chemo-mechanical process. Cellulose 18:1085–1095

Kang YK, Park CH, Kim J, Kang TJ (2007) Application of electrospun polyurethane web to breathable water-proof fabrics. Fibers Polym 8:564–570

Khatri Z, Wei K, Kim BS, Kim IS (2011a) Effect of deacetylation on wicking behavior of co-electrospun cellulose acetate/polyvinyl alcohol nanofibers blend. Carbohydr Polym 87:2183–2188

Khatri Z, Memon MH, Khatri A, Tanwari A (2011b) Cold Pad-Batch dyeing method for cotton fabric dyeing with reactive dyes using ultrasonic energy. Ultrason Sonochem 18:1301–1307

Khatri A, White M, Padhye R, Momin NH (2012a) The use of reflectance measurements in the determination of diffusion of reactive dyes into cellulosic fiber. Color Res Appl. doi:10.1002/col.21764

Khatri Z, Mayakrishnan G, Hirata Y, Wei K, Kim IS (2012b) Cationic-cellulose nanofibers: preparation and dyeability with anionic reactive dyes for apparel application. Carbohydr Polym 91:434–443

Khatri Z, Khatri A, Saleem U, Mayakrishnan G, Kim BS, Wei K, Kim IS (2012c) Pad dyeing of cellulose acetate nanofibres with disperse dyes. Color Technol. doi:10.1111/j.1478-4408.2012.00409.x

Kim BS, Kimura N, Kim HK, Watanabe K, Kim IS (2011) Thermal insulation, antibacterial and mold properties of breathable nanofiber-laminated wallpapers. J Nanosci Nanotechnol 11:4929–4933

Nishiyama Y, Langan P, Chanzy H (2002) Crystal structure and hydrogen-bonding system in cellulose Iβ from synchrotron X-ray and neutron fiber diffraction. J Am Chem Soc 24:9074–9082

Nishiyama Y, Sugiyama J, Chanzy H, Langan P (2003) Crystal structure and hydrogen bonding system in cellulose Ia from synchrotron X-ray and neutron fiber diffraction. J Am Chem Soc 125:14300–14306

Shore J (1995) Dyeing with reactive dyes. In: Shore J (ed) Cellulosic dyeing. Society of Dyers and Colourists, United Kingdom, pp 189–245

Sumin L, Kimura D, Yokoyama A, Lee K, Park JC, Kim IS (2009) The effects of laundering on the mechanical properties of mass-produced nanofiber web for use in wear. Text Res J 79:1085–1090

Sumin L, Kimura D, Lee KH, Park JC, Kim IS (2010) The effect of laundering on the thermal and water transfer properties of mass-produced laminated nanofiber web for use in wear. Text Res J 80:99–105

Tang S, Baker GA, Ravula S, Jones J, Zhao H (2012) Novel PEG-functionalized ionic liquids for cellulose dissolution and saccharification. Green Chem 14:2922–2932

Yoon B, Lee S (2011) Designing waterproof breathable materials based on electrospun nanofibers and assessing the performance characteristics. Fibers Polym 12:57–64

Acknowledgments

This work was supported by Grants for Excellent Graduate Schools, MEXT, Japan.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Khatri, Z., Arain, R.A., Jatoi, A.W. et al. Dyeing and characterization of cellulose nanofibers to improve color yields by dual padding method. Cellulose 20, 1469–1476 (2013). https://doi.org/10.1007/s10570-013-9893-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-013-9893-7