Abstract

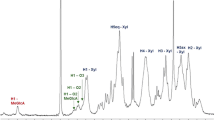

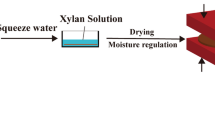

We report of cellulose and arabinoglucuronoxylan (AGX) blend films made from wood polymers extracted from one and the same tree. Blends were prepared by dissolution of wood polymers in 1-ethyl-3-methylimidazolium acetate (EmimAc). Films were produced by casting EmimAc solution followed by coagulation in ethanol. The films were optically transparent, fully amorphous as shown by wide angle X-ray scattering, and free from EmimAc residues as shown by Fourier transform infrared spectroscopy. Mechanical properties were analyzed as a function of water content. The plasticizing effect of water on the films was evidenced by both tensile and dynamical mechanical analysis measurements with humidity scans. Equilibrium moisture content (w/w) was measured at different relative humidities and the proportional water uptake was clearly related to the mechanical properties. We found good mechanical properties independent of the polysaccharide composition and an increased Young’s modulus at low humidities with a maximum at approximately 20 % AGX content. The strengthening effect was removed after leaching the AGX from the films. This study shows potential applications of biopolymer extracted from trees as future packaging.

Similar content being viewed by others

References

Albersheim P, Darvill A, Roberts K, Sederoff R, Staehelin A (2010) Principles of cell wall architecture and assembly. Plant cell walls: from chemistry to biology. Garland Science, Taylor and Francis Group, London, pp 227–272

Bosmans TJ, Stépán AM, Toriz G, Renneckar S, Karabulut E, Wågberg L, Gatenholm P (2014) Assembly of debranched xylan from solution and on nanocellulosic surfaces. Biomacromolecules 15:924–930. doi:10.1021/bm4017868

Cao Y, Li H, Zhang Y, Zhang J, He J (2010) Structure and properties of novel regenerated cellulose films prepared from cornhusk cellulose in room temperature ionic liquids. J Appl Polym Sci 116:547–554

Dammström S, Gatenholm P (2008) Preparation and properties of cellulose/xylan nanocomposites. In: Characterization of the cellulosic cell wall. Blackwell, Oxford, pp 53–63. doi:10.1002/9780470999714.ch5

El Seoud OA, Koschella A, Fidale LC, Dorn S, Heinze T (2007) Applications of ionic liquids in carbohydrate chemistry: a window of opportunities. Biomacromolecules 8:2629–2647

Escalante A, Gonçalves A, Bodin A, Stepan A, Sandström C, Toriz G, Gatenholm P (2012) Flexible oxygen barrier films from spruce xylan. Carbohydr Polym 87:2381–2387

Fengel D, Wegener G (1983) Wood: chemistry, ultrastructure, reactions. Walter de Gruyter, Berlin

Fink HP, Weigel P, Purz HJ, Ganster J (2001) Structure formation of regenerated cellulose materials from NMMO-solutions. Prog Polym Sci 26:1473–1524. doi:10.1016/S0079-6700(01)00025-9

Froix MF, Nelson R (1975) The interaction of water with cellulose from nuclear magnetic resonance relaxation times. Macromolecules 8:726–730

Froschauer C, Hummel M, Iakovlev M, Roselli A, Schottenberger H, Sixta H (2013) Separation of hemicellulose and cellulose from wood pulp by means of ionic liquid/cosolvent systems. Biomacromolecules 14:1741–1750. doi:10.1021/bm400106h

Gröndahl M, Eriksson L, Gatenholm P (2004) Material properties of plasticized hardwood xylans for potential application as oxygen barrier films. Biomacromolecules 5:1528–1535

Hauru LKJ, Hummel M, King AWT, Kilpeläinen I, Sixta H (2012) Role of solvent parameters in the regeneration of cellulose from ionic liquid solutions. Biomacromolecules 13:2896–2905. doi:10.1021/bm300912y

Heredia A, Jiménez A, Guillén R (1995) Composition of plant cell walls Zeitschrift für Lebensmittel. Untersuchung und Forschung 200:24–31

Höije A, Sternemalm E, Heikkinen S, Tenkanen M, Gatenholm P (2008) Material properties of films from enzymatically tailored arabinoxylans. Biomacromolecules 9:2042–2047. doi:10.1021/bm800290m

Howsmon JA (1949) Water sorption and the poly-phase structure of cellulose fibers. Text Res J 19:152–162

Isobe N, Kim U-J, Kimura S, Wada M, Kuga S (2011) Internal surface polarity of regenerated cellulose gel depends on the species used as coagulant. J Colloid Interface Sci 359:194–201

Kilpeläinen I, Xie H, King A, Granstrom M, Heikkinen S, Argyropoulos DS (2007) Dissolution of wood in ionic liquids. J Agric Food Chem 55:9142–9148

Klemm D, Heublein B, Fink H-P, Bohn A (2005) Cellulose: fascinating biopolymer and sustainable raw material. Angew Chem Int Ed 44:3358–3393. doi:10.1002/anie.200460587

Köhnke T, Pujolras C, Roubroeks JP, Gatenholm P (2008) The effect of barley husk arabinoxylan adsorption on the properties of cellulose fibres. Cellulose 15:537–546

Kosan B, Michels C, Meister F (2008) Dissolution and forming of cellulose with ionic liquids. Cellulose 15:59–66

Laity P, Glover P, Hay J (2002) Composition and phase changes observed by magnetic resonance imaging during non-solvent induced coagulation of cellulose. Polymer 43:5827–5837

Lerouxel O, Cavalier DM, Liepman AH, Keegstra K (2006) Biosynthesis of plant cell wall polysaccharides—a complex process. Curr Opin Plant Biol 9:621–630

Lindman B, Karlström G, Stigsson L (2010) On the mechanism of dissolution of cellulose. J Mol Liq 156:76–81

Mäki-Arvela P, Anugwom I, Virtanen P, Sjöholm R, Mikkola J-P (2010) Dissolution of lignocellulosic materials and its constituents using ionic liquids—a review. Ind Crops Prod 32:175–201

Medronho B, Lindman B (2014) Competing forces during cellulose dissolution: from solvents to mechanisms. Curr Opin Colloid Interface Sci 19:32–40

Medronho B, Romano A, Miguel MG, Stigsson L, Lindman B (2012) Rationalizing cellulose (in) solubility: reviewing basic physicochemical aspects and role of hydrophobic interactions. Cellulose 19:581–587

Nakamura K, Hatakeyama T, Hatakeyama H (1981) Studies on bound water of cellulose by differential scanning calorimetry. Text Res J 51:607–613. doi:10.1177/004051758105100909

Nakamura K, Hatakeyama T, Hatakeyama H (1983) Effect of bound water on tensile properties of native cellulose. Text Res J 53:682–688. doi:10.1177/004051758305301108

Östlund Å, Idström A, Olsson C, Larsson PT, Nordstierna L (2013) Modification of crystallinity and pore size distribution in coagulated cellulose films. Cellulose 20:1657–1667

Pinkert A, Marsh KN, Pang S, Staiger MP (2009) Ionic liquids and their interaction with cellulose. Chem Rev 109:6712–6728. doi:10.1021/cr9001947

Ragauskas AJ et al (2006) The path forward for biofuels and biomaterials. Science 311:484–489. doi:10.1126/science.1114736

Reiter W-D (2002) Biosynthesis and properties of the plant cell wall. Curr Opin Plant Biol 5:536–542

Rogers RD, Seddon KR (2003) Ionic liquids-solvents of the future? Science 302:792–793. doi:10.1126/science.1090313

Salmen N, Back G (1977) The influence of water on the glass transition temperature of cellulose. Tappi 60:137–140

Šimkovic I, Tracz A, Kelnar I, Uhliariková I, Mendichi R (2014) Quaternized and sulfated xylan derivative films. Carbohydr Polym 99:356–364

Simmons TJ et al (2011) Preparation of synthetic wood composites using ionic liquids. Wood Sci Technol 45:719–733

Sun Q, Mandalika A, Elder T, Nair SS, Meng X, Huang F, Ragauskas AJ (2014) Nanocomposite film prepared by depositing xylan on cellulose nanowhiskers matrix. Green Chem 16:3458–3462

Sundberg J, Toriz G, Gatenholm P (2013) Moisture induced plasticity of amorphous cellulose films from ionic liquid. Polymer 54:6555–6560

Swatloski RP, Spear SK, Holbrey JD, Rogers RD (2002) Dissolution of cellose with ionic liquids. J Am Chem Soc 124:4974–4975

Theander O, Westerlund EA (1986) Studies on dietary fiber. 3. Improved procedures for analysis of dietary fiber. J Agric Food Chem 34:330–336. doi:10.1021/jf00068a045

Timell T (1961) Isolation of galactoglucomannans from the wood of gymnosperms. Tappi 44:88–96

Torimoto T, Tsuda T, Okazaki K, Kuwabata S (2009) New frontiers in materials science opened by ionic liquids. Adv Mater Weinheim 22:1196–1221

Troshenkowa S, Wawro D (2010) Dissolved state of cellulose in ionic liquids—the impact of water. Fibres Text East Eur 18:80

Turner MB, Spear SK, Holbrey JD, Rogers RD (2004) Production of bioactive cellulose films reconstituted from ionic liquids. Biomacromolecules 5:1379–1384

Wise LE, Murphy M, D’Addieco AA (1946) Chlorite holocellulose, its fractionation and bearing on summative wood analysis and on studies on the hemicelluloses. Pap Trade J 122:35–42

Wu RL, Wang XL, Li F, Li HZ, Wang YZ (2009) Green composite films prepared from cellulose, starch and lignin in room-temperature ionic liquid. Bioresour Technol 100:2569–2574

Zhang H, Wu J, Zhang J, He J (2005) 1-Allyl-3-methylimidazolium chloride room temperature ionic liquid: a new and powerful nonderivatizing solvent for cellulose. Macromolecules 38:8272–8277

Zhao Q, Yam RCM, Zhang B, Yang Y, Cheng X, Li RKY (2009) Novel all-cellulose ecocomposites prepared in ionic liquids. Cellulose 16:217–226

Zhu S et al (2006) Dissolution of cellulose with ionic liquids and its application: a mini-review. Green Chem 8:325–327

Zografi G, Kontny M, Yang A, Brenner G (1984) Surface area and water vapor sorption of macrocrystalline cellulose. Int J Pharm 18:99–116

Acknowledgments

The Knut and Alice Wallenberg Foundation is gratefully acknowledged for funding the Wallenberg Wood Science Center. Volodymyr Kuzmenko and Vratislav Langer are acknowledged for their assistance with the XRD analysis.

Conflict of interest

The authors declare that there are no conflicts of interest.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Sundberg, J., Toriz, G. & Gatenholm, P. Effect of xylan content on mechanical properties in regenerated cellulose/xylan blend films from ionic liquid. Cellulose 22, 1943–1953 (2015). https://doi.org/10.1007/s10570-015-0606-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-015-0606-2