Abstract

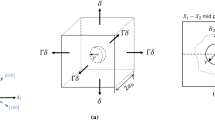

Micro-mechanical 2D cell model studies have revealed ductile failure during intense shearing to be governed by the interaction of neighbouring voids, which collapse to micro-cracks and continuously rotate and elongate until coalescence occurs. For a three-dimensional void structure, this implies significant straining of the matrix material located on the axis of rotation. In particular, the void surface material is severely deformed during shearing and void surface contact is established early in the deformation process. This 3D effect intensifies with decreasing stress triaxiality and complicates the numerical analysis, which is also reflected in published literature. Rather than moving towards very low triaxiality shearing, work has focused on extracting wide-ranging results for moderate stress triaxiality (T ~ 1), in order to achieve sufficient understanding of the influence of initial porosity, void shape, void orientation etc. The objective of this work is to expand the range of stress triaxiality usually faced in 3D cell model studies, such that intense shearing is covered, and to bring forward details on the porosity and void shape evolution. The overall material response is presented for a range of initial material configurations and loading conditions. In addition, a direct comparison to corresponding 2D cell model predictions for circular cylindrical voids under plane strain shearing is presented. A quantitatively good agreement of the two model configurations (2D vs. 3D) is obtained and similar trends are predicted. However, the additional layer of matrix material, connecting voids in the transverse direction, is concluded to significantly influence the void shape evolution and to give rise to higher overall ductility. This 3D effect is demonstrated for various periodic distributions of voids.

Similar content being viewed by others

References

ABAQUS (2010) ABAQUS Theory Manual, version 6.10, SIMULIA Corp

Anderson P, Fleck N, Johnson K (1990) Localization of plastic deformation in shear due to micro-cracks. J Mech Phys Solids 38: 681–699

Bao Y, Wierzbicki T (2004) On fracture locus in the equivalent strain and stress triaxiality space. Int J Mech Sci 46: 81–98

Barsoum I, Faleskog J (2007a) Rupture mechanisms in combined tension and shear—experiments. Int J Solids Struct 44: 1768–1786

Barsoum I, Faleskog J (2007b) Rupture mechanisms in combined tension and shear—micromechanics. Int J Solids Struct 44: 5481–5498

Barsoum I, Faleskog J (2011) Micromechanical analysis on the influence of the lode parameter on void growth and coalescence. Int J Solids Struct 48: 925–938

Belytschko T, Liu W, Moran B (2000) Nonlinear finite elements for continua and structures. Wiley, New York

Benzerga A (2002) Micromechanics of coalescence in ductile fracture. J Mech Phys Solids 50: 1331–1362

Chu A, Needleman A (1980) Void nucleation effects in biaxially stretched sheets. J Eng Mater Technol 102: 249–256

Dahl J, Nielsen K, Tvergaard V (2012) Effect of contact conditions on void coalescence at low stress triaxiality Shearing. J Appl Mech. doi:10.1115/1.4005565

Fleck N, Hutchinson J, Tvergaard V (1989) Softening by void nucleation and growth in tension and shear. J Mech Phys Solids 37: 515–540

Gao X, Zhang G (2010) A study on the effect of the stress state on ductile fracture. Int J Damage Mech 19: 75–94

Gologanu M, Leblond J, Devaux J (1993) Approximate models for ductile metals containing nonspherical voids—case of axisymmetrical prolate ellipsoidal cavities. J Mech Phys Solids 41: 1723–1754

Gologanu M, Leblond J, Devaux J (1994) Approximate models for ductile metals containing nonspherical voids—case of axisymmetrical oblate ellipsoidal cavities. J Eng Mater Technol 116: 290–297

Gologanu M, Leblond J, Perrin G, Devaux J (1997) Recent extensions of Gurson’s model for porous ductile metals. In: Continuum micromechanics, Springer, Berlin, pp 61–106

Gurson A (1977) Continuum theory of ductile rupture by void nucleation and growth—part I: yield criteria and flow rules for porous ductile media. ASME J Eng Mater Technol 99: 2–15

Jodlowski T (2011) Mechanics of growth and coalescence of pre-existing voids in a ductile matrix. PhD thesis, École polytechnique fédérale de lausanne, Université de Lausanne

Koplik J, Needleman A (1988) Void growth and coalescence in porous plastic solids. Int J Solids Struct 24: 835–853

Lassance D, Fabrègue D, Delannay F, Pardoen T (2007) Micromechanics of room and high temperature fracture in 6xxx Al alloys. Prog Mater Sci 52: 62–129

Leblond JB, Mottet G (2008) A theoretical approach of strain localization within thin planar bands in porous ductile materials. C R Mecanique 336: 176–189

Li Z, Steinmann P (2006) RVE-based studies on the coupled effects of void size and void shape on yield behavior and void growth at micron scales. Int J Plast 22: 1195–1216

McVeigh C, Vernerey F, Wing K, Moran B, Olson G (2007) An interactive micro-void shear localization mechanism in high strength steels. J Mech Phys Solids 55: 225–244

Nahshon K, Hutchinson J (2008) Modification of the Gurson model for shear. Euro J Mech A/Solids 27: 1–17

Needleman A (1972) Void growth in an elastic-plastic medium. J Appl Mech 39: 964–970

Nielsen K (2010) Predicting failure response of spot welded joints using recent extensions to the Gurson model. Comp Mater Sci 48: 71–82

Nielsen K, Tvergaard V (2011) Failure by void coalescence in metallic materials containing primary and secondary voids subject to intense shearing. Int J Solids Struct 48: 1255–1267

Pardoen T, Hutchinson J (2000) An extended model for void growth and coalescence. J Mech Phys Solids 48: 2467–2512

Scheyvaerts F (2008) Multiscale modeling of ductile fracture in heterogeneous metallic alloys. PhD thesis, École polytechnique de Louvain, Université catholique de Louvain

Simar A, Nielsen K, de Meester B, Tvergaard V, Pardoen T (2010) Micro-mechanical modeling of ductile failure in 6005A aluminium using a physics based strain hardening law including stage IV. Eng Frac Mech 77: 2491–2503

Tekoglu C, Leblond JB, Pardoen T (2012) A criterion for the onset of void coalescence under combined tension and shear (submitted)

Thomason P (1990) Ductile fracture of metals. Pergamon press, Oxford

Tvergaard V (1981) Influence of voids on shear band instabilities under plane strain conditions. Int J Fract 17: 389–407

Tvergaard V (1982) On localization in ductile materials containing spherical voids. Int J Frac 18: 237–252

Tvergaard V (1989) Numerical study of localization in a void-sheet. Int J Solids Struct 25: 1143–1156

Tvergaard V (2008) Shear deformation of voids with contact modelled by internal pressure. Int J Mech Sci 50: 1459–1465

Tvergaard V (2009) Behaviour of voids in a shear field. Int J Fract 158: 41–49

Tvergaard V (2012) Effect of stress-state and spacing on voids in a shear-field (to appear)

Tvergaard V, Needleman A (1984) Analysis of the cup-cone fracture in a round tensile bar. Acta Metall 32: 157–169

Tvergaard V, Nielsen K (2010) Relations between a micro-mechanical model and a damage model for ductile failure in shear. J Mech Phys Solids 58: 1243–1252

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Nielsen, K.L., Dahl, J. & Tvergaard, V. Collapse and coalescence of spherical voids subject to intense shearing: studied in full 3D. Int J Fract 177, 97–108 (2012). https://doi.org/10.1007/s10704-012-9757-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10704-012-9757-4