Abstract

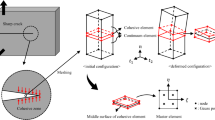

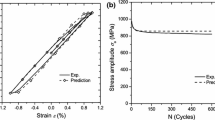

Fatigue crack growth is simulated for an elastic solid with a cyclic cohesive zone model (CZM). Material degradation and thus separation follows from the current damage state, which represents the amount of maximum transferable traction across the cohesive zone. The traction–separation relation proposed in the cyclic CZM includes non-linear paths for both un- and reloading. This allows a smooth transition from reversible to damaged state. The exponential traction–separation envelope is controlled by two shape parameters. Moreover, a lower bound for damage evolution is introduced by a local damage dependent endurance limit, which enters the damage evolution equation. The cyclic CZM is applied to mode I fatigue crack growth under \(K_{\mathrm{I}}\)-controlled external loading conditions. The influences of the model parameters with respect to static failure load \(K_{\mathrm{0}}\), threshold load \(\varDelta K_{\mathrm{th}}\) and Paris parameters \(m, C\) are investigated. The study reveals that the proposed endurance limit formulation is well suited to control the ratio \(\varDelta K_{\mathrm{th}}/K_{\mathrm{0}}\) independent of \(m\) and \(C\). An identification procedure is suggested to identify the cohesive parameters with the help of Wöhler diagrams and fatigue crack growth rate curves.

Similar content being viewed by others

Notes

The respective ABAQUS UEL subroutine and visualisation utilities (Roth et al. 2012) are available on request from the authors.

References

Anderson T (2005) Fracture mechanics: fundamentals and applications, 3rd edn. Taylor and Francis, London

Barenblatt G (1962) The mathematical theory of equilibrium cracks in brittle fracture. In: Dryden HL, GKFvdD Th von Kármán, Howarth L (eds) Advances in applied mechanics, vol 7, Elsevier, pp 55–129

Bouvard J, Chaboche J, Feyel F, Gallerneau F (2009) A cohesive zone model for fatigue and creep-fatigue crack growth in single crystal superalloys. Int J Fatigue 31(5):868–879

Brocks W, Cornec A, Scheider I (2003) Computational aspects of nonlinear fracture mechanics. In: Milne I, Ritchie R, Karihaloo B (eds) Comprehensive structural integrity—numerical and computational methods, vol 3. Elsevier, Amsterdam, pp 127–209

Camacho G, Ortiz M (1996) Computational modelling of impact damage in brittle materials. Int J Solids Struct 33(20–22):2899–2938

Dugdale D (1960) Yielding of steel sheets containing slits. J Mech Phys Solids 8(2):100–104

Fleck N, Kang K, Ashby M (1994) Overview no. 112: the cyclic properties of engineering materials. Acta Metall Mater 42(2):365–381

Goyal VK, Johnson ER, Davila CG (2004) Irreversible constitutive law for modeling the delamination process using interfacial surface discontinuities. Compos Struct 65(3–4):289–305

Haibach E (1989) Betriebsfestigkeit: Verfahren und Daten zur Bauteilberechnung. VDI-Verlag GmbH, Düsseldorf

Hütter G (2013) Multi-scale simulation of crack propagation in the ductile-brittle transition region. Dissertation, TU Bergakademie Freiberg

Hütter G, Mühlich U, Kuna M (2011) Simulation of local instabilities during crack propagation in the ductile–brittle transition region. Eur J Mech A/Solids 30(3):195–203

Kroon M, Faleskog J (2005) Micromechanics of cleavage fracture initiation in ferritic steels by carbide cracking. J Mech Phys Solids 53(1):171–196

Lemaitre J (1996) A course on damage mechanics, 2nd edn. Springer, New York

Liu J, Yuan H, Liao R (2010) Prediction of fatigue crack growth and residual stress relaxations in shot-peened material. Mater Sci Eng A 527(21–22):5962–5968

Lucas L, Black T, Jones D (2008) Use of cohesive elements in fatigue analysis. In: American society of mechanical engineers, pressure vessels and piping division (publication) PVP, ASME, vol 2, pp 13–25

Nguyen O, Repetto E, Ortiz M, Radovitzky R (2001) A cohesive model of fatigue crack growth. Int J Fract 110(4):351–369

Ortiz M, Pandolfi A (1999) Finite-deformation irreversible cohesive elements for three-dimensional crack-propagation analysis. Int J Numer Methods Eng 44(9):1267–1282

Paris P, Erdogan F (1963) A critical analysis of crack propagation laws. J Basic Eng-T Asme 85(4):528–533

Radaj D, Vormwald M (2007) Ermüdungsfestigkeit: Grundlagen für Ingenieure. Springer, London

Rice J (1968) A path-independent integral and approximate analysis of strain concentration by notches and cracks. ASME J Appl Mech 35:379–386

Ritchie R (1988) Mechanisms of fatigue crack propagation in metals, ceramics and composites: role of crack tip shielding. Mater Sci Eng 103(1):15–28

Roe K, Siegmund T (2003) An irreversible cohesive zone model for interface fatigue crack growth simulation. Eng Fract Mech 70(2):209–232

Roth S, Kuna M (2013) Finite element analyses of fatigue crack growth under small scale yielding conditions modelled with a cyclic cohesive zone approach, COMPLAS XII. In: Oñate E, Owen D, Peric D, Suárez B (eds) Computational plasticity XII—fundamentals and applications. CIMNE, Barcelona, pp 1075–1086

Roychowdhury S, Arun Roy Y (2002) Ductile tearing in thin aluminum panels: experiments and analyses using large-displacement, 3-d surface cohesive elements. Eng Fract Mech 69(8):983–1002

Roth S, Hütter G, Mühlich U, Nassauer B, Zybell L, Kuna M (2012) Visualisation of user defined finite elements with ABAQUS/Viewer. GACM Report 7:7–14

Schütz W (1967) Über eine Beziehung zwischen der Lebens- dauer bei konstanter und bei veränderlicher Beanspruchungs amplitude und ihre Anwendbarkeit auf die Bemessung von Flugzeugbauteilen. Zeitschrift für Flugwissenschaften 15(11):407–419

Smith J (1942) The effect of range of stress on the fatigue strength of metals. In: Engineering experiment station bulletin, vol 334. University of Illinois

Suresh S (1998) Fatigue of materials, 2nd edn. Cambridge University Press, Cambridge

Scheider I, Mosler J (2011) Novel approach for the treatment of cyclic loading using a potential-based cohesive zone model. Proc Eng 10:2164–2169

Schwalbe KH, Scheider I, Cornec A (2013) Guidelines for applying cohesive models to the damage behaviour of engineering materials and structures. Springer, Berlin

Siegmund T (2004) A numerical study of transient fatigue crack growth by use of an irreversible cohesive zone model. Int J Fatigue 26(9):929–939

Tvergaard V, Hutchinson JW (1992) The relation between crack growth resistance and fracture process parameters in elastic–plastic solids. J Mech Phys Solids 40(6):1377–1397

Xu XP, Needleman A (1993) Void nucleation by inclusion debonding in a crystal matrix. Model Simul Mater Sci 1(2):111–132

Xu Y, Yuan H (2009a) Computational analysis of mixed-mode fatigue crack growth in quasi-brittle materials using extended finite element methods. Eng Fract Mech 76(2):165–181

Xu Y, Yuan H (2009b) On damage accumulations in the cyclic cohesive zone model for xfem analysis of mixed-mode fatigue crack growth. Comput Mater Sci 46(3):579–585

Yang B, Mall S, Ravi-Chandar K (2001) A cohesive zone model for fatigue crack growth in quasibrittle materials. Int J Solids Struct 38(22–23):3927–3944

Acknowledgments

This work was performed within the Cluster of Excellence “Structure Design of Novel High-Performance Materials via Atomic Design and Defect Engineering (ADDE)” that is financially supported by the European Union (European regional development fund) and by the Ministry of Science and Art of Saxony (SMWK).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Roth, S., Hütter, G. & Kuna, M. Simulation of fatigue crack growth with a cyclic cohesive zone model. Int J Fract 188, 23–45 (2014). https://doi.org/10.1007/s10704-014-9942-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10704-014-9942-8