Abstract

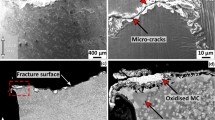

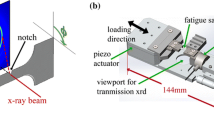

MC carbide particles (with Hafnium and/or Tantalum as constituent metallic element, M) were observed to crack extensively in a cast polycrystalline nickel-base superalloy, MAR-M247, when subjected to low-cycle fatigue loading at room temperature. High resolution secondary electron images taken on the surface of a double edge notch test specimen revealed that approximately half the carbide particles cracked in the highly-strained notch section of the specimen. These images further illustrated that the average surface area of cracked particles was approximately three times that of the uncracked particles. Additional analysis illustrated that the cracks within a large number of particles aligned nearly perpendicular to the loading direction. However, high aspect ratio particles (with aspect ratio \({>}3\)) were prone to incubate cracks aligned along its major axis, independent of the loading direction. Additionally, forward-scattered imaging often showed a high density of slip bands interaction with most of the particles which cracked. The life limiting crack growth in MAR-M247 was observed to be crystallographic in nature, as the crack grew along slip bands as measured by high-resolution electron backscatter diffraction, even after spanning many grains. Statistically representative microstructure models of MAR-M247 were generated and used in the crystal plasticity finite element simulations. As expected, there was a significant variation in the computed stress state among constituent carbide particles. The stress state of the carbide particles was found to be heavily influenced by the stress in surrounding grains and the orientation of the major axis of the particles with respect to applied load direction. For particles that intersect the free-surface, stress was found to be highly concentrated at the free surface and a positive correlation between the magnitude of free-surface area and the maximum principal stress was found. Additionally, high stress concentrations were observed in regions where carbide particles intersect grain boundaries.

Similar content being viewed by others

References

Beaudoin AJ, Acharya A, Chen SR et al (2000) Consideration of grain-size effect and kinetics in the plastic deformation of metal polycrystals. Acta Mater 48:3409–3423. doi:10.1016/S1359-6454(00)00136-1

Boismier DA, Sehitoglu H (1990) Thermo-mechanical fatigue of Mar-M247: part 1–experiments. J Eng Mater Technol Trans ASME 112:68. doi:10.1115/1.2903189

Bor HY, Chao CG, Ma CY (1999) The effects of Mg microaddition on the mechanical behavior and fracture mechanism of MAR-M247 superalloy at elevated temperatures. Metall Mater Trans A 30:551–561. doi:10.1007/s11661-999-0047-3

Bowman R, Ritzert F, Freedman M (2004) Evaluation of candidate materials for a high-temperature stirling convertor heater head. Space technology and applications international forum. Melville, NY, pp 821–828

Bozek JE, Hochhalter JD, Veilleux MG et al (2008) A geometric approach to modeling microstructurally small fatigue crack formation: I. Probabilistic simulation of constituent particle cracking in AA 7075–T651. Model Simul. Mater Sci Eng 16:65007. doi:10.1088/0965-0393/16/6/065007

Brindley KA, Kirka MM, Fernandez-Zelaia P, Neu RW (2015) Thermomechanical fatigue of Mar-M247: Extension of a unified constitutive and life model to higher temperatures. J Eng Mater Technol Trans ASME. doi:10.1115/1.4029908

Castelluccio GM, McDowell DL (2012) Effect of annealing twins on crack initiation under high cycle fatigue conditions. J Mater Sci 48:2376–2387. doi:10.1007/s10853-012-7021-y

Cerrone A, Stein C, Pokharel R et al (2015) Implementation and verification of a microstructure-based capability for modeling microcrack nucleation in LSHR at room temperature. Model Simul Mater Sci Eng 23:35006. doi:10.1088/0965-0393/23/3/035006

Chen J, Lee J, Jo C et al (1998) MC carbide formation in directionally solidified MAR-M247 LC superalloy. Mater Sci Eng A 247:113–125. doi:10.1016/S0921-5093(97)00761-2

Feltham P (1957) Grain growth in metals. Acta Metall 5:97–105. doi:10.1016/0001-6160(57)90136-0

Gell M, Leveran GR (1968) The fatigue of the nickel-base superalloy Mar-M200 in single crystal and columnar-grained forms at room temperature. Trans TMS-AIME 242:1869–1879

Geuzaine C, Remacle JF (2009) Gmsh: a 3-D finite element mesh generator with built-in pre- and post-processing facilities. Int J Numer Methods Eng 79:1309–1331. doi:10.1002/nme.2579

Groeber MA (2007) Development of an automated characterization-representation framework for the modeling of polycrystalline materials in 3D. Ph.D. thesis, Ohio State University, Columbus, Ohio

Groeber M, Jackson M (2014) DREAM.3D: a digital representation environment for the analysis of microstructure in 3D. Integr Mater Manuf Innov 3:5. doi:10.1186/2193-9772-3-5

Janowski GM (1985) The effect of tantalum on the structure/properties of two polycrystalline nickel-base superalloys: B-1900+Hf and MAR-M247, NASA Contractor Report 174847

Jiang J, Yang J, Zhang T et al (2015) On the mechanistic basis of fatigue crack nucleation in Ni superalloy containing inclusions using high resolution electron backscatter diffraction. Acta Mater. doi:10.1016/j.actamat.2015.06.035

Kamıṣ T, Bagcı S, Tütüncü HM et al (2011) Ab initio calculation of phonons in bulk HfC and the HfC(001)(1 \(\times \) 1) surface. Philos Mag 91:946–957. doi:10.1080/14786435.2010.536177

Karamched PS, Wilkinson AJ (2011) High resolution electron back-scatter diffraction analysis of thermally and mechanically induced strains near carbide inclusions in a superalloy. Acta Mater 59:263–272. doi:10.1016/j.actamat.2010.09.030

Kartal ME, Kiwanuka R, Dunne FPE (2014) Determination of sub-surface stresses at inclusions in single crystal superalloy using HR-EBSD, crystal plasticity and inverse eigenstrain analysis. Int J Solids Struct 67–68:27–39. doi:10.1016/j.ijsolstr.2015.02.023

Kaufman M (1984) Properties of Cast Mar-M-247 for Turbine Blisk Applications. In: Superalloys 1984 (fifth international symposium). TMS, pp 43–52

Kocks F (1976) Laws for work-hardening and low-temperature creep. J Eng Mater Technol 98:76–85. doi:10.1115/1.3443340

Kotval PS, Venables JD, Calder RW (1972) The role of hafnium in modifying the microstructure of cast nickel-base superalloys. Metall Trans 3:457–462. doi:10.1007/BF02642049

Kuhn HA, Sockel HG (1988) Comparison between experimental determination and calculation of elastic properties of nickel-base superalloys between 25 and \(1200\;^{\circ }\text{ C }\). Phys Status Solidi 110:449–458. doi:10.1002/pssa.2211100217

Li G, Li G (2010) Microstructure and mechanical properties of hafnium carbide coatings synthesized by reactive magnetron sputtering. J Coatings Technol Res 7:403–407. doi:10.1007/s11998-009-9225-x

Liao J-H, Bor H-Y, Chao C-G, Liu T-F (2010) Effects of rhenium on microstructure and phase stability of MAR-M247 Ni-base fine-grain superalloy. Mater Trans 51:810–817. doi:10.2320/matertrans.M2009331

MacSleyne JP, Simmons JP, De Graef M (2008) On the use of moment invariants for the automated analysis of 3D particle shapes. Model Simul Mater Sci Eng 16:45008. doi:10.1088/0965-0393/16/4/045008

Margolin H (1998) Polycrystalline yielding–perspectives on its onset. Acta Mater 46:6305–6309. doi:10.1016/S1359-6454(98)00227-4

Miao J, Pollock TM, Wayne Jones J (2009) Crystallographic fatigue crack initiation in nickel-based superalloy René 88DT at elevated temperature. Acta Mater 57:5964–5974. doi:10.1016/j.actamat.2009.08.022

Murakami Y, Endo M (1994) Effects of defects, inclusions and inhomogeneities on fatigue strength. Int J Fatigue 16:163–182. doi:10.1016/0142-1123(94)90001-9

Nathal MV, Maier RD, Ebert LJ (1982) The influence of cobalt on the tensile and stress-rupture properties of the nickel-base superalloy MAR-M247. Metall Trans A 13:1767–1774. doi:10.1007/BF02647832

Neumann P (1999) Analytical solution for the incompatibility stresses at twin boundaries in cubic crystals. In: Fatigue. Beijing, pp 107–114

Przybyla C, Prasannavenkatesan R, Salajegheh N, McDowell DL (2010) Microstructure-sensitive modeling of high cycle fatigue. Int J Fatigue 32:512–525. doi:10.1016/j.ijfatigue.2009.03.021

Ruggles TJ, Fullwood DT, Kysar JW (2016) Resolving geometrically necessary dislocation density onto individual dislocation types using EBSD-based continuum dislocation microscopy. Int J Plast 76:231–243. doi:10.1016/j.ijplas.2015.08.005

Salajegheh N, Prasannavenkatesan R, McDowell DL et al (2014) Finite element simulation of shielding/intensification effects of primary inclusion clusters in high strength steels under fatigue loading. J Eng Mater Technol 136:31003. doi:10.1115/1.4027380

Sangid MD, Maier HJ, Sehitoglu H (2011c) The role of grain boundaries on fatigue crack initiation—an energy approach. Int J Plast 27:801–821. doi:10.1016/j.ijplas.2010.09.009

Sangid MD, Maier HJ, Sehitoglu H (2011b) A physically based fatigue model for prediction of crack initiation from persistent slip bands in polycrystals. Acta Mater 59:328–341. doi:10.1016/j.actamat.2010.09.036

Sangid MD, Maier HJ, Sehitoglu H (2011a) An energy-based microstructure model to account for fatigue scatter in polycrystals. J Mech Phys Solids 59:595–609. doi:10.1016/j.jmps.2010.12.014

Schneider CA, Rasband WS, Eliceiri KW (2012) NIH Image to ImageJ: 25 years of image analysis. Nat Methods 9:671–675. doi:10.1038/nmeth.2089

Schreiber JG, Thieme LG (2008) GRC supporting technology for NASA’s Advanced Stirling Radioisotope Generator (ASRG). AIP Conf Proc 969:582–592. doi:10.1063/1.2845018

Sehitoglu H, Boismier DA (1990) Thermo-mechanical fatigue of Mar-M247: part 2–life prediction. J Eng Mater Technol 112:80. doi:10.1115/1.2903191

Shenoy MM, Kumar RS, McDowell DL (2005) Modeling effects of nonmetallic inclusions on LCF in DS nickel-base superalloys. Int J Fatigue 27:113–127. doi:10.1016/j.ijfatigue.2004.06.008

Šmíd M, Horník V, Hutař P et al (2016) High cycle fatigue damage mechanisms of MAR-M 247 superalloy at high temperatures. Trans Indian Inst Met 69:393–397. doi:10.1007/s12666-015-0817-0

Šmíd M, Kunz L, Hutař P, Hrbáček K (2014) High cycle fatigue of nickel-based superalloy MAR-M 247 at high temperatures. Procedia Eng 74:329–332. doi:10.1016/j.proeng.2014.06.273

Szczotok A, Rodak K (2012) Microstructural studies of carbides in MAR-M247 nickel-based superalloy. IOP Conf Ser Mater Sci Eng 35:12006. doi:10.1088/1757-899X/35/1/012006

Szczotok A, Szala J, Cwajna J, Hetmańczyk M (2006) Selection of etching methods of primary carbides in MAR-M247 nickel-base superalloy for computer-aided quantitative metallography. Mater Charact 56:348–354. doi:10.1016/j.matchar.2005.10.011

Warner JE, Bomarito GF, Hochhalter JD (2016) Scalable implementation of finite elements by NASA _ Implicit (ScIFEi), NASA/TM—2016–219180. Hampton, Virginia

Wawro SW (1982) MC carbide structures in Mar-M247, NASA Contractor Report 167892

Wood JG, Carroll C, Matejczyk D, Penswick L (2005) Advanced 80 \(\text{ W }_{{\rm e}}\) stirling convertor phase II development progress. In: 3rd International energy conversion engineering conference. doi:10.2514/6.2005-5559

Yeratapally SR, Glavicic MG, Hardy M, Sangid MD (2016) Microstructure based fatigue life prediction framework for polycrystalline nickel-base superalloys with emphasis on the role played by twin boundaries in crack initiation. Acta Mater. doi:10.1016/j.actamat.2016.01.038

Zhang J, Prasannavenkatesan R, Shenoy MM, McDowell DL (2009) Modeling fatigue crack nucleation at primary inclusions in carburized and shot-peened martensitic steel. Eng Fract Mech 76:315–334. doi:10.1016/j.engfracmech.2008.10.011

Zhang T, Collins DM, Dunne FPE, Shollock BA (2014) Crystal plasticity and high-resolution electron backscatter diffraction analysis of full-field polycrystal Ni superalloy strains and rotations under thermal loading. Acta Mater 80:25–38. doi:10.1016/j.actamat.2014.07.036

Zhang T, Jiang J, Britton B et al (2016) Crack nucleation using combined crystal plasticity modelling, high-resolution digital image correlation and high-resolution electron backscatter diffraction in a superalloy containing non-metallic inclusions under fatigue. Proc R Soc A Math Phys Eng Sci 472:20150792. doi:10.1098/rspa.2015.0792

Zhang T, Jiang J, Shollock BA et al (2015) Slip localization and fatigue crack nucleation near a non-metallic inclusion in polycrystalline nickel-based superalloy. Mater Sci Eng A 641:328–339. doi:10.1016/j.msea.2015.06.070

Acknowledgements

This project was funded by the NASA Engineering and Safety Center. SY and MDS acknowledge support by the National Institute of Aerospace (grant number 2712-001).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yeratapally, S.R., Hochhalter, J.D., Ruggles, T.J. et al. Investigation of fatigue crack incubation and growth in cast MAR-M247 subjected to low cycle fatigue at room temperature. Int J Fract 208, 79–96 (2017). https://doi.org/10.1007/s10704-017-0213-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10704-017-0213-3