Abstract

The use of thermoelements is a commonly applied method in industry and engineering. It provides a wide measurement range of temperature, a direct voltage signal from the transducer, low cost of the thermoelement, and its resistance to many unfavorable factors which occur in an industrial environment. Unfortunately, thermoelements may not be resistant to interferences of a strong electromagnetic field because of the nature and design of a transducer. Induction heating is the most commonly used type of heating, at present, for metals. In order to guarantee the correctness of the carried out heating process, it is essential to control the temperature of the heated element. The impact of a strong electromagnetic field upon the thermocouple temperature measurement of the inductively heated elements has been analyzed in this paper. The experiment includes dozens of measurements where the following parameters have been varied: frequency of the current which feeds the heating inductor, power supplied to the heating system, geometry of heat inductor, and the charge material and its geometrical dimensions. Interferences of the power-line frequency have been eliminated in part of the carried out measurements.

Similar content being viewed by others

1 Introduction

Induction heating is a popular method used for heating in metal processing. It is used both for melting induction furnaces, and pre-heating before plastic working or heat treatment [1–3]. The method has become so popular due to its heating nature because the heat is emitted directly inside the heated charge and it is not transferred through the surface. The emission of heat sources directly inside the charge enables generation of a high heating intensity. In many processes, e.g., hardening, it is essential to reach a particular temperature range of the heated charge. Thermoelements are commonly used for controlling the temperature. However, in the process of heating, the indicated temperature is quite often unreliable [4]. On the basis of the performed tests, measurement deviations range from several up to tens of percent. Measurement results become reliable when the electromagnetic field stops being active. According to the literature [5, 6], the electromagnetic field can disturb the measurement made by the thermoelement in three ways: by inducing a voltage in the thermoelement circuit, by galvanic coupling and the passage of current between the heated element and the meter circuit, as well as by induction heating of the thermoelement itself.

The aim of the measurement tests performed by the authors of this paper was to test which mechanisms of the measurement interferences are crucial for the temperature measurement carried out in a strong electromagnetic field and whether it is possible to eliminate these interferences.

2 Induction Heating

There is a wide variety of equipment for induction heating; therefore, they can be grouped according to the following typical criteria: geometry, current supply frequency, and power of the heating system. As far as geometry is concerned, induction heating includes the equipment for heating flat charges, the equipment for heating cylindrical charges, and non-typical heaters. As far as the current supply frequency is concerned, there are heaters which use the power-line frequency (50 Hz or 60 Hz), medium frequency (500 Hz to 10 kHz), high frequency (10 kHz to 300 kHz), and extremely high frequency (300 kHz to 27.12 MHz) [7, 8]. Taking into account the power, the division is quite typical: low power equipment (up to 50 kW), medium power (up to 200 kW), and high power (above 200 kW) [7].

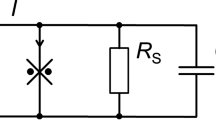

An induction heater consists of three basic elements: current supply source, heating inductor, and charge feeding system. A typical diagram of an induction heater has been presented in Fig. 1.

The basis for describing the electromagnetic phenomena in a heating inductor of the heater is Maxwell’s system of equations supplemented by constitutive equations and the generalized Ohm’s law [8]. Omitting the displacement current and applying the vector potential allows a description of the electromagnetic field of an induction heater by the equation

where A is the magnetic vector potential, \(\mu , \sigma \) are the magnetic permeability and conductivity, \(\omega \) is the angular frequency, and \({{\varvec{J}}}_\mathrm{s}\) is the source current density.

The source current (\({{\varvec{J}}}_\mathrm{s})\), running through the heating inductor, induces an electromagnetic field which generates eddy currents in all conducting objects which are in the area of its interaction, particularly in the zone of the heating inductor and charge. Eddy currents, running through the medium which features the resistivity, generate heat sources with a volumetric density,

where J is the eddy current density.

The distribution of the power density for various frequencies has been studied in Refs. [9–12]. A simplified analysis of the electromagnetic field incident upon the flat half-space enables determination of the expression for the depth of the magnetic field penetration [8],

the quantity which defines how deep from the metal surface the electromagnetic field generates heat sources. It has been assumed that the electromagnetic field has a considerable impact at a depth of 1.5 \(\delta \), and further on, it actually disappears. The objects of thickness considerably smaller than the depth of the field are ‘transparent’ for the electromagnetic field, and eddy currents are not induced in them.

3 Thermoelements

The basic phenomenon which makes the temperature measurements possible, applying thermoelements, is the effect which has been observed by Seebeck, i.e., the effect of electric current flow in a circuit which consists of two different conduits with their connectors placed at different temperatures. A quantitative description of this phenomenon has been based on a formula which defines Seebeck’s thermoelectric force for a homogeneous conductor whose ends are placed at different temperatures [6, 11]

where \(E\) is the thermoelectric force and \(\sigma _{A}\) is the Seebeck’s coefficient of metal A.

Taking into consideration a couple of joined conductors and assuming that the free ends of the conductors are at the same temperature (reference temperature), the formula for the thermoelectric force of a closed loop has the form [6, 13]

where \(e_\mathrm{AB} (T_\mathrm{p})\) is the contact potential difference on a junction of A and B metals at the temperature of measurement and \(e_\mathrm{AB} (T_\mathrm{o})\) is the contact potential difference on a junction of A and B metals at the reference temperature. The generated electromagnetic force, proportional to the temperature difference, is relatively small, and the system used for measuring it should have high inner resistance.

There are also three additional phenomena which accompany the passage of current in conductors and conductor junctions placed at different temperatures. These are the Peltier effect, the Thompson effect, and the Joule heat emission effect. Peltier’s and Thompson’s effects have been described by

where d\(Q\) is the amount of heat transferred between junctions (Peltier), \(p_\mathrm{AB}\) is Peltier’s coefficient for the junction of metals A and B, \(t\) is Thompson’s coefficient, \(I\) is the electric current intensity, and d\(Q_{T}\) is the amount of heat per unit of length in a homogeneous metal (Thompson). Joule’s effect as expressed by Eq. 2 defines the amount of heat emitted inside the metal while the current flows. Equations 2, 6, and 7 reveal that the heat flow or heat emission depends on the current intensity in the circuit.

The high inner resistance of a transducer and the very low voltage signal obtained from a thermoelement (at the level of about 40 \(\upmu \)V for a thermoelement of type K) makes the measurement system highly susceptible to electromagnetic interferences. It is possible to reduce the interferences by shielding or by twisting the thermoelement wires. Another way of reducing the impact of interferences of a changeable nature is the application of wave filters.

The susceptibility to electromagnetic interferences as well as the time constants of the measurement depend on the type of thermoelement (Fig. 2). In the experiment carried out by the authors of this paper, two types of thermocouples of different construction have been used: an exposed thermocouple and an insulated thermocouple (Fig. 2c). The exposed thermocouple has been formed by two wires made of chromel and alumel, 0.35 mm thick and 250 mm long, placed in a shield made of ceramic beads, twisted around each other. The insulated thermocouple had a shield of 3 mm diameter, and it was 250 mm long. Supply wires have been placed in a shield.

Types of coated thermoelements according to [3]: (a) insulated junction, welded-in bottom, (b) junction welded in a bottom, (c) insulated junction, shield without a seam, and (d) sticking out junction

4 Measurement

The multi-variant experiment, including over 12 measurements, has been carried out in order to examine the impact of a strong electromagnetic field upon the thermocouple measurement of temperature. The variants included the supply current frequency, the heating inductor geometry (Fig. 3), the material of a heated charge, the charge dimensions, the type of thermocouple used (Fig. 4), and the power supplied to the system. The measurement system has been presented schematically in Fig. 5.

The heating has been carried out in different heating inductors depending on the power supply source. Two different ingots were heated: aluminum cylindrical ingot, 135 mm high with 20 mm diameter, and steel ingot (ferromagnetic), 153 mm high with 24 mm diameter. The temperature was measured 5 mm from the wall at the top of the ingot. The following methodology has been used in order to examine the impact of the electromagnetic field upon the obtained measurement results: the charge was heated for 10 s (measurement in EM field) and then the power supply source was switched off for 5 s (measurement without EM field). A complete measurement cycle was 120 s. The temperature was recorded every second, and it was written to a file. Results of the experiment are listed in Table 1.

The temperature dependences of the heated steel charge on the heating time, for insulated and exposed thermocouples, are presented in Fig. 6. After switching off the source of the electromagnetic field, the temperatures measured by the two types of thermocouples were quite close (in the time range between 10 s and 15 s, 25 s and 30 s, 40 s and 45 s, 55 s and 60 s, 70 s and 75 s, 85 s and 90 s, as well as 100 s and 105 s). At every moment the source was switched off, there was a decrease of the temperature as measured by the exposed thermocouple. This was due to the induced electromagnetic interferences in the thermoelement. Such an effect did not occur in the insulated thermocouple. Its shield was made of non-magnetic steel that shielded the electromagnetic field but heat was generated mainly in the ferromagnetic charge.

Temperature values measured for the P3 variant have been presented in Fig. 7. It can be clearly seen that interferences which have been induced in that case in the exposed thermocouple are considerably high. The value of the voltage on the thermocouple transducer exceeds the measurement range of the converter which has been connected to a thermoelement. Correct values can be observed only when the electromagnetic field has been switched off (Fig. 8 variant P3).

While the aluminum charge has been heated, the thermocouple shield has been heated up as well (variant P4, Fig. 8). The shield was made of non-magnetic steel, and therefore, it heated more intensively in the electromagnetic field than does an aluminum cylinder positioned in the heating inductor. The observed temperature which has been recorded by the insulated thermocouple was a result of heat generated in the heating process of the thermocouple shield and aluminum charge. It was significantly higher than the temperature recorded by the exposed thermocouple (when there was no electromagnetic field during the measurement that was carried out) and it can be assumed that this temperature is the reference temperature. Temperatures recorded for P3 and P4 variants have been presented in Fig. 8. The temperatures for the P3 variant shown in Fig. 8 are only those which were measured when the electromagnetic field was not active.

Data presented in Fig. 9 have revealed that the electromagnetic field of 330 kHz frequency heated the thermoelements that were used in the experiment. In the insulated thermocouple, there was a step increase of temperature, matching the switching on and off mode of the electromagnetic field until a quasi-steady state was reached at \(550\,{^\circ }\text{ C }\). The exposed thermocouple has also heated when EM was active, and it cooled when the electromagnetic field was switched off (detail A). The quasi-steady state was about \(100\,{^\circ }\text{ C }\), however, in such circumstances when the electromagnetic field was active, some disturbances have been induced which caused that the temperature indicated by the system had a constant value at the level of \(100\,{^\circ }\text{ C }\) when the electromagnetic field was active (Fig. 9, detail B).

Summing up the measurements which were carried out for induction heating at a frequency of 330 kHz, it can be stated that there have always been some errors in the examined measurement system. There were two problems as follows:

-

heating up of the thermoelement or its shield (both the exposed and insulated thermocouples),

-

induction of electromagnetic interferences (exposed thermocouple).

Unfortunately, the depth of the electromagnetic field penetration (Eq. 3) at 330 kHz frequency is 0.75 mm for non-magnetic steel, 0.74 mm for NiCr alloy, and 0.48 mm for Alumel. Thus, for elements of comparable thickness and larger than the depth of the electromagnetic field penetration, the process of thermoelement heating as a result of electromagnetic field activity is unavoidable.

The only acceptable, accurate results have been obtained for the temperature measurement of the ferromagnetic charge using the insulated thermocouple. The ferromagnetic charge shielded the thermoelement terminal and, at the same time, it was heated up much stronger due to the activity of the electromagnetic field than the thermoelement itself. It should be noted here that the temperature during the experiment did not exceed the Curie temperature.

In the part of the experiment carried out for a frequency of 50 Hz, the heating of the thermocouple shield and the thermocouple wires resulting from electromagnetic field activity did not occur. For that frequency, the depth of the electromagnetic field penetration was 60 mm for non-magnetic steel, 59 mm for NiCr alloy, and 38 mm for alumel. It was many times larger than the thickness of the thermocouple shield or the thickness of its wires. This can be clearly observed in Figs. 10 and 11 which present the temperature records when only the thermocouple has been placed in the heating inductor. The temperature was actually constant. A slight increase of temperature was probably due to the heating of the thermoelement caused by the heat insulation of a heating inductor (heat insulation was warmed in earlier experiments to about \(35\,{^\circ }\text{ C }\)).

The induced electromagnetic interferences are still an unsolved problem, independent of the frequency. The majority of convertors have filters for the power supply frequency which eliminates the interferences of 50 Hz or 60 Hz frequency. The problem of eliminating interferences is probably realized by the change of the integration time constant of the AD converter where the method of double integration is used for processing. The results of the measurements carried out with an insulated thermocouple and an exposed thermocouple using proper filtering of line interferences are presented in Figs. 12 and 13. There is high convergence of the obtained results (variants P9 and P11). They show a proper and improper filtering of the interferences of the power supply frequency. When the interferences of power supply frequencies were filtered improperly, then the readings of the measurement system were unreliable, independent of which type of thermocouple (exposed or insulated) had been used.

5 Conclusions

Induction heating is a frequently used heating method in the metallurgical industry. The temperature reached by a charge when it leaves the heater is one of the most important technological parameters. Thermoelements are used for controlling the temperature. These are some of their advantages: low cost, wide range of measured temperatures, they can be used in a polluted environment, and with vapor and gases produced in the process of heating. However, in the process of induction heating, temperature readings are often unreliable. In practice, measurement deviations can range from several to tens of percent. When the electromagnetic field stops being active, the measurement results become reliable again. A series of experiments have been performed and presented in this paper, and their aim was to check the reliability of temperature measurement when the electromagnetic field was active. Twelve measurement cycles for various frequencies of the electromagnetic field and different types of thermocouples have been carried out. On the basis of the measurements which were made, it can be observed that:

-

errors always appear in the examined measurement system at a frequency of 330 kHz. The following basic problems are:

-

thermoelement or its shield is directly heated by the electromagnetic field (exposed or insulated thermocouple),

-

electromagnetic interferences were induced (exposed thermocouple),

-

for that frequency it was not possible to eliminate the errors resulting from the induced electromagnetic interferences using a line interference filter,

-

-

for a frequency of 50 Hz in the examined system, there were only errors resulting from the induced electromagnetic interferences. These interferences could be easily eliminated by fitting in the measurement system of a line interference filter.

In the course of tests, a simple low-pass filter has been used for eliminating interferences but it was not effective at such a high input resistance of the measurement system. Filtering at a digital side seems to be an interesting method of eliminating interferences. It requires a much higher frequency of signal sampling (about 1 MHz). It is quite likely that signal filtration at the digital side of the equipment would be more flexible and effective. Possibilities of that type of filtration will be developed in the course of further research since the problem is essential from a practical point of view.

References

G. Siwiec, J. Botor, B. Machulec, Arch. Metall. 48, 209 (2003)

B. Oleksiak, G. Siwiec, A. Blacha, J. Lipart, Arch. Mater. Sci. Eng. 44, 39 (2010)

G. Siwiec, Arch. Metall. Mater. 57, 951 (2012)

G. Cymerman, Electromagnetic Interference in Thermocouple Temperature Measurement (Master’s Thesis, Silesian University of Technology, Poland, 2005) [in Polish]

L. Michalski, K. Eckersdorf, Temperature Measurements (WNT, Warszawa, Poland, 1986) [in Polish]

L. Michalski, K. Eckersdorf, J. Kucharski, Thermometry, Instruments and Methods (Lodz University of Technology, Poland, 1998) [in Polish]

M. Hering, Electrothermics Basics II (WNT, Warszawa, Poland, 1992) [in Polish]

Cz. Sajdak, E. Samek, Induction Heating and Application of Theoretical Foundations (Silesia Press, Katowice, Poland, 1985) [in Polish]

R. Przylucki, A. Smalcerz, Metalurgija 52, 235 (2013)

S. Golak, R. Zagorski, Metalurgija 52, 215 (2013)

M. Niklewicz, A. Smalcerz, A. Kurek, Przeglad Elektrotechniczny 84, 219 (2008)

C. Sajdak, S. Golak, A. Kurek, Przeglad Elektrotechniczny 83, 67 (2007)

American Society for Testing and Materials, A Manual on the Use of Thermocouples in Temperature Measurement, 4th edn. (ASTM, New York, 1993)

Acknowledgments

This research work was carried out within Project No. N N508 479438 financially sponsored by the Polish Ministry of Science and Higher Education.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution License which permits any use, distribution, and reproduction in any medium, provided the original author(s) and the source are credited.

About this article

Cite this article

Smalcerz, A., Przylucki, R. Impact of Electromagnetic Field upon Temperature Measurement of Induction Heated Charges. Int J Thermophys 34, 667–679 (2013). https://doi.org/10.1007/s10765-013-1423-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10765-013-1423-1