Abstract

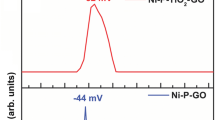

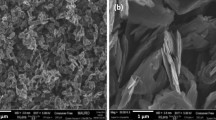

The structure and properties of pulse electrodeposited Ni–W alloy-based nanocomposite coatings, reinforced with varying amounts of graphene oxide (GO) particles, have been evaluated. An aqueous sulfate–citrate electrolytic bath with a suspension of GO particles was used for the deposition of Ni–W/GO composite coatings. Using X-ray diffraction, scanning and transmission electron microscopy with selected area electron diffraction, the effect of graphene oxide particles on microstructural characteristics of the nanocomposite coatings was examined with emphasis on the evolution of constituent phases, morphology, grain size (16–30 nm), and micro-strain. The GO particle reinforcement in the Ni–W alloy reduces the average matrix grain size and increases micro-strain in the alloy matrix. The presence of GO particles in the matrix of nanocomposite coatings is found to strongly influence both nanoindentation hardness and elastic modulus, obtained by analyzing the load–displacement curves, lower the friction coefficient, and enhance the corrosion resistance.

Graphic abstract

Similar content being viewed by others

References

Feng Q, Li T, Yue H, Qi K, Bai F, Jin J (2008) Preparation and characterization of nickel nano-Al2O3 composite coatings by sediment co-deposition. Appl Surf Sci 254:2262–2268. https://doi.org/10.1016/j.apsusc.2007.09.014

Singh DK, Singh VB (2012) Electrodeposition and characterization of Ni–TiC composite using N-methylformamide bath. Mater Sci Eng A 532:493–499. https://doi.org/10.1016/j.msea.2011.10.115

Sahu BP, Sarangi CK, Mitra R (2018) Effect of Zr content on structure property relations of Ni-Zr alloy thin films with mixed nanocrystalline and amorphous structure. Thin Solid Films 660:31–45. https://doi.org/10.1016/j.tsf.2018.05.050

Lampke T, Wielage B, Dietrich D, Leopold A (2006) Details of crystalline growth in co-deposited electroplated nickel films with hard (nano) particles. Appl Surf Sci 253:2399–2408. https://doi.org/10.1016/j.apsusc.2006.04.060

Bahrololoom ME, Sani R (2005) The influence of pulse plating parameters on the hardness and wear resistance of nickel–alumina composite coatings. Surf Coat Technol 192:154–163. https://doi.org/10.1016/j.surfcoat.2004.09.023

Beltowska-Lehman E, Goral A, Indyka P (2011) Electrodeposition and characterization of Ni/Al2O3 nanocomposite coatings. Arch Metall Mater 56:919–931. https://doi.org/10.2478/v10172-011-0101-1

Benea L (2009) Electrodeposition and tribocorrosion behaviour of ZrO2–Ni composite coatings. J Appl Electrochem 39:1671. https://doi.org/10.1007/s10800-009-9859-5

Chen L, Wang L, Zeng Z, Zhang J (2006) Effect of surfactant on the electrodeposition and wear resistance of Ni–Al2O3 composite coatings. Mater Sci Eng A 434:319–325. https://doi.org/10.1016/j.msea.2006.06.098

Chen W, He Y, Gao W (2010) Electrodeposition of sol-enhanced nanostructured Ni-TiO2 composite coatings. Surf Coat Technol 204:2487–2492. https://doi.org/10.1016/j.surfcoat.2010.01.036

Qu NS, Chan KC, Zhu D (2004) Pulse co-electrodeposition of nano Al2O3 whiskers nickel composite coating. Scr Mater 50:1131–1134. https://doi.org/10.1016/j.scriptamat.2004.01.027

Spanou S, Pavlatou EA (2010) Pulse electrodeposition of Ni/nano-TiO2 composites: effect of pulse frequency on deposits properties. J Appl Electrochem 40:1325–1336. https://doi.org/10.1007/s10800-010-0080-3

Lajevardi SA, Shahrabi T (2010) Effects of pulse electrodeposition parameters on the properties of Ni–TiO2 nanocomposite coatings. Appl Surf Sci 256:6775–6781. https://doi.org/10.1016/j.apsusc.2010.04.088

Xue YJ, Liu HB, Lan MM, Li JS, Li H (2010) Effect of different electrodeposition methods on oxidation resistance of Ni–CeO2 nanocomposite coating. Surf Coat Technol 204:3539–3545. https://doi.org/10.1016/j.surfcoat.2010.04.009

Parida G, Chaira D, Chopkar M, Basu A (2011) Synthesis and characterization of Ni-TiO2 composite coatings by electro-co-deposition. Surf Coat Technol 205:4871–4879. https://doi.org/10.1016/j.surfcoat.2011.04.102

Baghery P, Farzam M, Mousavi AB, Hosseini M (2010) Ni–TiO2 nanocomposite coating with high resistance to corrosion and wear. Surf Coat Technol 204:3804–3810. https://doi.org/10.1016/j.surfcoat.2010.04.061

Wang W, Hou FY, Wang H, Guo HT (2005) Fabrication and characterization of Ni–ZrO2 composite nano-coatings by pulse electrodeposition. Scr Mater 53:613–618. https://doi.org/10.1016/j.scriptamat.2005.04.002

Maurin G, Lavanant A (1995) Electrodeposition of nickel/silicon carbide composite coatings on a rotating disc electrode. J Appl Electrochem 25:1113–1121. https://doi.org/10.1007/BF00242538

Nowak P, Socha RP, Kaisheva M, Fransaer J, Celis JP, Stoinov Z (2000) Electrochemical investigation of the codeposition of SiC and SiO2 particles with nickel. J Appl Electrochem 30:429–437. https://doi.org/10.1023/A:1003979117146

Stroumbouli M, Gyftou P, Pavlatou EA, Spyrellis N (2005) Codeposition of ultrafine WC particles in Ni matrix composite electrocoatings. Surf Coat Technol 195:325–332. https://doi.org/10.1016/j.surfcoat.2004.06.034

Surender M, Basu B, Balasubramaniam R (2004) Wear characterization of electrodeposited Ni–WC composite coatings. Tribol Int 37:743–749. https://doi.org/10.1016/j.triboint.2004.04.003

Wang SC, Wei WCJ (2003) Kinetics of electroplating process of nano-sized ceramic particle/Ni composite. Mater Chem Phys 78:574–580. https://doi.org/10.1016/S0254-0584(01)00564-8

Zhu XB, Cai C, Zheng GQ, Zhang Z, Li JF (2011) Electrodeposition and corrosion behaviour of nanostructured Ni-TiN composite films. Trans Nonferrous Met Soc China 21:2216–2224. https://doi.org/10.1016/S1003-6326(11)60998-9

Pompei E, Magagnin L, Lecis N, Cavallotti PL (2009) Electrodeposition of nickel–BN composite coatings. Electrochim Acta 54:2571–2574. https://doi.org/10.1016/j.electacta.2008.06.034

Khazrayie MA, Aghdam ARS (2010) Si3N4/Ni nanocomposite formed by electroplating: effect of average size of nanoparticulates. Trans Nonferrous Met Soc China 20:1017–1023. https://doi.org/10.1016/S1003-6326(09)60251-X

An BG, Li LX, Li HX (2008) Electrodeposition in the Ni-plating bath containing multi-walled carbon nanotubes. Mater Chem Phys 110:481–485. https://doi.org/10.1016/j.matchemphys.2008.03.007

Chen XH, Chen CS, Xiao HN, Cheng FQ, Zhang G, Yi GJ (2005) Corrosion behavior of carbon nanotubes–Ni composite coating. Surf Coat Technol 191:351–356. https://doi.org/10.1016/j.surfcoat.2004.04.055

Karim MRA, Pavese M, Ambrosio EP, Ugues D, Lombardi M, Biamino S, Badini C, Fino P (2013) Production and characterization of Ni and Cu composite coatings by electrodeposition reinforced with carbon nanotubes or graphite nanoplatelets. J Phys 439:012019. https://doi.org/10.1088/1742-6596/439/1/012019

Stankovich S, Dikin DA, Dommett GH, Kohlhaas KM, Zimney EJ, Stach EA, Piner RD, Nguyen ST, Ruoff RS (2006) Graphene-based composite materials. Nature 442:282. https://doi.org/10.1038/nature04969

Szeptycka B, Gajewska-Midzialek A, Babul T (2016) Electrodeposition and corrosion resistance of Ni-Graphene composite coatings. J Mater Eng Perform 25:3134–3138. https://doi.org/10.1007/s11665-016-2009-4

Kuang D, Xu L, Liu L, Hu W, Wu Y (2013) Graphene-nickel composites. Appl Surf Sci 273:484–490. https://doi.org/10.1016/j.apsusc.2013.02.066

Badrayyana S, Bhat DK, Shenoy S, Ullal Y, Hegde AC (2015) Novel Fe–Ni-Graphene composite electrode for hydrogen production. Int J Hydrog Energy 40:10453–10462. https://doi.org/10.1016/j.ijhydene.2015.06.040

Eliaz N, Sridhar TM, Gileadi E (2005) Synthesis and characterization of nickel tungsten alloys by electrodeposition. Electrochim Acta 50:2893–2904. https://doi.org/10.1016/j.electacta.2004.11.038

Rupert TJ, Trelewicz JR, Schuh CA (2012) Grain boundary relaxation strengthening of nanocrystalline Ni-W alloys. J Mater Res 27:1285–1294. https://doi.org/10.1557/jmr.2012.55

Zemanova M, Krivosudska M, Chovancova M, Jorik V (2011) Pulse current electrodeposition and corrosion properties of Ni-W alloy coatings. J Appl Electrochem 41:1077–1085. https://doi.org/10.1007/s10800-011-0331-y

Anicai L (2007) Ni-W alloys coatings as ecological alternative for chromium plating: evaluation of corrosion behaviour. Corros Rev 25:607–620. https://doi.org/10.1515/CORRREV.2007.25.5-6.607

Allahyarzadeh MH, Aliofkhazraei M, Rezvanian AR, Torabinejad V, Sabour Rouhaghdam AR (2016) Ni-W electrodeposited coatings: characterization, properties and applications. Surf Coat Technol 307:978–1010. https://doi.org/10.1016/j.surfcoat.2016.09.052

Low CTJ, Wills RGA, Walsh FC (2006) Electrodeposition of composite coatings containing nanoparticles in a metal deposit. Surf Coat Technol 201:371–383. https://doi.org/10.1016/j.surfcoat.2005.11.123

Mote VD, Purushotham Y, Dole BN (2012) Williamson-Hall analysis in estimation of lattice strain in nanometer-sized ZnO particles. J Theor Appl Phys 6:6. https://doi.org/10.1186/2251-7235-6-6

Li Y, Wang G, Liu S, Zhao S, Zhang K (2018) The preparation of Ni/GO composite foils and the enhancement effects of GO in mechanical properties. Compos B 135:43–48. https://doi.org/10.1016/j.compositesb.2017.09.064

Wang J, Lei W, Deng Y, Xue Z, Qian H, Liu W (2019) Effect of current density on microstructure and corrosion resistance of Ni-graphene oxide composite coating electrodeposited under supercritical carbon dioxide. Surf Coat Technol 358:765–774. https://doi.org/10.1016/j.surfcoat.2018.09.061

Aswin S, Varghese S (2014) Tribology study of graphene-aluminium nanocomposites. Int J Mech Prod Eng 2:29–33

Liu L, Zhang J, Zhao J, Liu F (2012) Mechanical properties of graphene oxides. Nanoscale 4:5910–5916. https://doi.org/10.1039/C2NR31164J

Song J, Zhang J, Lin C (2013) Influence of graphene oxide on the tribological and electrical properties of PMMA composites. J Nanomater 2013:846102. https://doi.org/10.1155/2013/846102

Ren Z, Meng N, Shehzad K, Xu Y, Qu S, Yu B, Luo JK (2015) Mechanical properties of nickel-graphene composites synthesized by electrochemical deposition. Nanotechnology 26:065706. https://doi.org/10.1088/0957-4484/26/6/065706

Zhang Z, Wu X, Jiang C, Ma N (2014) Electrodeposition of Ni matrix composite coatings containing ZrC particles. Surf Eng 30:21–25. https://doi.org/10.1179/1743294413Y.0000000185

Trelewicz JR, Schuh CA (2007) The Hall–Petch breakdown in nanocrystalline metals; a crossover to glass-like deformation. Acta Mater 55:5948–5958. https://doi.org/10.1016/j.actamat.2007.07.020

Chokshi AH, Rosen A, Karch J, Gleiter H (1989) On the validity of the Hall-Petch relationship in nanocrystalline materials. Scr Metall 23:1679–1684. https://doi.org/10.1016/0036-9748(89)90342-6

Masumura RA, Hazzledine PM, Pande CS (1998) Yield stress of fine grained materials. Acta Mater 46:4527–4534. https://doi.org/10.1016/S1359-6454(98)00150-5

Wu H, Liu F, Gong W, Ye F, Hao L, Jiang J, Han S (2015) Preparation of Ni–P–GO composite coatings and its mechanical properties. Surf Coat Technol 272:25–32. https://doi.org/10.1016/j.surfcoat.2015.04.028

Parhizkar N, Dolati A, Aghababazadeh R, Lalegani Z (2016) Electrochemical deposition of Ni–TiN nanocomposite coatings and the effect of sodium dodecyl sulphate surfactant on the coating properties. Bull Mater Sci 39:1021–1027. https://doi.org/10.1007/s12034-016-1238-3

Kumar M, Mishra S, Mitra R (2013) Effect of Ar:N2 ratio on structure and properties of Ni–TiN nanocomposite thin films processed by reactive RF/DC magnetron sputtering. Surf Coat Technol 228:100–114. https://doi.org/10.1016/j.surfcoat.2013.04.014

Cieslak G, Trzaska M (2018) Preparation and properties of nanocrystalline Ni/graphene composite coatings deposited by electrochemical method. Pol J Chem Technol 20:29–34. https://doi.org/10.2478/pjct-2018-0005

Poot M, Van der Zant HSJ (2008) Nanomechanical properties of few-layer graphene membranes. Appl Phys Lett 92:063111. https://doi.org/10.1063/1.2857472

Frank IW, Tanenbaum PM, Van der Zande AM, McEuen PL (2007) Mechanical properties of suspended graphene sheets. J Vac Sci Technol B 25:2558–2561. https://doi.org/10.1116/1.2789446

Chen J, Li J, Xiong D, He Y, Ji Y, Qin Y (2016) Preparation and tribological behavior of Ni-graphene composite coating under room temperature. Appl Surf Sci 361:49–56. https://doi.org/10.1016/j.apsusc.2015.11.094

Liu C, Su F, Liang J (2015) Producing cobalt–graphene composite coating by pulse electrodeposition with excellent wear and corrosion resistance. Appl Surf Sci 351:889–896. https://doi.org/10.1016/j.apsusc.2015.06.018

Yasin G, Arif M, Shakeel M, Dun Y, Zuo Y, Khan WQ, Tang Y, Khan A, Nadeem M (2018) Exploring the nickel–graphene nanocomposite coatings for superior corrosion resistance: manipulating the effect of deposition current density on its morphology, mechanical properties, and erosion-corrosion performance. Adv Eng Mater 20:1701166. https://doi.org/10.1002/adem.201701166

Acknowledgements

Ministry of Earth Sciences (MoES), India, is acknowledged here for providing the financial support to carry out this work.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Sarangi, C.K., Sahu, B.P., Mishra, B.K. et al. Pulse electrodeposition and characterization of graphene oxide particle-reinforced Ni–W alloy matrix nanocomposite coatings. J Appl Electrochem 50, 265–279 (2020). https://doi.org/10.1007/s10800-019-01387-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10800-019-01387-y