Abstract

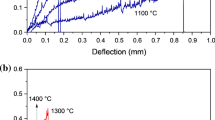

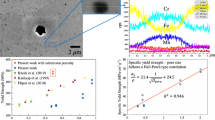

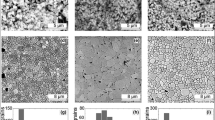

Metal and ceramic structures are being fabricated by pressureless sintering of compacted powders. As the powdered compacts are sintered, the pore volume fraction, generally referred to as porosity, decreases while the elastic mechanical properties increase. In this investigation, a new relationship is drawn between porosity and the evolution of elastic mechanical properties in pure ceramic and metal specimens. To develop this relationship, disk specimens are prepared from Nickel and Alumina powders, then sintered to different temperatures. The evolution of porosity is then evaluated from density measurements, while the corresponding elastic mechanical properties are measured using the ultrasonic wave propagation technique. These experimental measurements are compared with several different descriptions: (1) a conventional power law formula, (2) a quadratic formula, (3) a numerical micromechanical porosity simulation, and (4) a new empirical formula that combines the effects of evolving particle cohesion on the elastic properties of the matrix material and the reduction of these properties due to porosity. For the Young’s modulus, the new empirical formula provides a better description than the alternative formulas. In the case of Poisson’s ratio, similar conclusions could be made. However, the Poisson’s ratio exhibited a different sensitivity to particle cohesion that was more directly related to the evolution of particle cohesion.

Similar content being viewed by others

References

Winter AN, Corff BA, Reimanis IE, Rabin BH (2000) J Am Ceram Soc 83:2147

German RM (1996) Sintering theory and practice. John Wiley and Sons

Shinagawa K (2003) JSME Int J Ser A 46:378

Shinagawa K (1999) Comp Mater Sci 13:276

Zhang B, Gasik M (2002) Comp Mater Sci 25:264

Jagota A, Scherer GW (1995) J Am Ceram Soc 78:521

Larsson PL, Biwa S, Storakers B (1996) Acta Mater 44:3655

Storakers B, Fleck NA, McMeeking RM (1999) J Mech Phys Solids 47:785

Bruck HA, Rabin BH (1999) J Mater Sci 34:2241

Ronald Munro G (1997) J Am Ceram Soc 80:1919

Pabst W, Gregorova E (2003) J Mater Sci Lett 22:959

Phani KK, Niyogi SK (1987) J Mater Sci 22:257

Roberts AP, Garboczi EJ (2002) Proc Roy Soc Lond 458:1033

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Bruck, H.A., Shabana, Y.M., Xu, B. et al. Evolution of elastic mechanical properties during pressureless sintering of powder-processed metals and ceramics. J Mater Sci 42, 7708–7715 (2007). https://doi.org/10.1007/s10853-007-1675-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-007-1675-x