Abstract

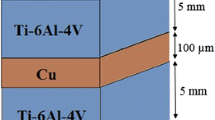

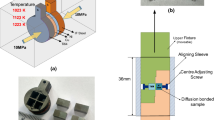

Ti-alloys, particularly TiAl, are becoming attractive for the use in the production of high-temperature components such as turbine blades and exhaust valves, owing to their low density. However, these components may not be cost-effectively cast totally from TiAl alloys and casting defects may occur in investment casting of these complex parts. Other manufacturing technologies, such as machining, cannot be economically employed in these very hard and brittle materials. Production of bi-material or even multi-material TiAl components can therefore offer an alternative fabrication route provided that the joining and joint properties of these materials are well understood. In this study, the diffusion bondability and joint characteristics of TiAl and Ti–6Al–4V alloys were studied. These two different materials were joined by using various bonding parameters. Metallographic investigations were conducted for characterization of the interface region of these dissimilar joints. Furthermore, the mechanical behavior of the bond interface was evaluated by shear testing. Both results on the microstructural and mechanical characterization provided the optimum bonding conditions for the production of TiAl–Ti6Al4V hybrid joints.

Similar content being viewed by others

References

Kim Y-W (1994) JOM 46:30

Yamaguchi M, Umakoshi Y (1990) Prog Mater Sci 34:1

Appel F, Wagner R (1998) Mater Sci Eng R 22:187

Patterson RA, Martin PL, Damkroger BK, Christodoulou L (1990) Weld J 69:39s

Çam G, Koçak M (1998) Int Mater Rev 43(1):1

Threadgill PL (1995) Mater Sci Eng A 192–193:640

Horn H (1991) Proc. Conf. Eurojoin 1, Strasbourg, France, November 1991, p 441

Bohm K-H et al (2003) Schweissen und Schneiden 55(1):20

Dahms M (1994) Adv Perform Mater 1:161

Çam G, Müllauer J, Koçak M (1997) Sci Technol Weld Join 2(5):213

Çam G, Clemens H, Gerling R, Koçak M (1999) Intermetallics 7:1025

Çam G, Koçak M (1999) J Mater Sci 34:3345

Çam G, Clemens H, Gerling R, Koçak M (1999) Z Metallkd 90(4):284

Holmquist M, Recina V, Pettersson B (1999) Acta Mater 47(6):1791

Holmquist M et al (1998) Scripta Mater 39(8):1101

Tuppen SJ, Bache MR, Voice WE (2005) Int J Fatigue 27:651

Ding J, Wang JN, Hu ZH, Ding DY (2002) Mater Sci Technol 18(8):908

Ferrante M, Pigoretti EV (2002) J Mater Sci 37:2825

Acknowledgements

This work was carried out within the German–Turkish joint project entitled “Solid State Joining of Advanced Light Weight High Temperature Materials for Aerospace and Automobile Applications” financed by KFA-Jülich Research Center, Germany and Tübitak, Ankara, Turkey. The authors would like to thank both organizations for their financial support. The authors also thank Dr. F. Appel for supplying the new generation C-containing TiAl alloy, Mr. K.-H. Bohm for his help in diffusion bonding, and Mrs. P.-M. Fischer for her help with optical microscopy.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Çam, G., Özdemir, U., Ventzke, V. et al. Microstructural and mechanical characterization of diffusion bonded hybrid joints. J Mater Sci 43, 3491–3499 (2008). https://doi.org/10.1007/s10853-007-2403-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-007-2403-2