Abstract

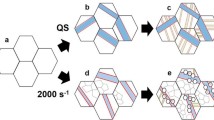

The compressive properties of ternary compound Cr2AlC at different temperatures and strain rates were studied. When tested at a strain rate of 5.6 × 10−4 s−1, the compressive strength decreases continuously from 997 ± 29 MPa at room temperature to 523 ± 7 MPa at 900 °C. The ductile-to-brittle transition temperature is measured to be in the range of 700 to 800 °C. When tested in the strain rate range of 5.6 × 10−5 to 5.6 × 10−3 s−1, Cr2AlC fails in a brittle mode at room temperature, whereas the deformation mode changes from a brittle to a ductile as the strain rate is lower than 5.6 × 10−4 s−1 when compressed at 800 °C. The compressive strength increases slightly with increasing strain rate at room temperature and it is less dependent on strain rate when tested at 800 °C. The plastic deformation mechanism of Cr2AlC was discussed in terms of dislocation-related activities, such as kink band formation, delamination, decohesion of grain boundary, and microcrack formation.

Similar content being viewed by others

References

Barsoum MW (2000) Prog Solid State Chem 28:201

Barsoum MW, El-Raghy T (1996) J Am Ceram Soc 79:1953

Tzenov N, Barsoum MW (2000) J Am Ceram Soc 83:825

Salama I, El-Raghy T, Barsoum MW (2002) J Alloys Compd 347:271

Jeitschko W, Nowotny H, Benesovsky F (1963) Monatsh Chem 94:672

Schuster JC, Nowotny H, Vaccaro C (1980) J Solid State Chem 32:213

Schneider JM, Sun ZM, Mertens R, Uestel F, Ahuja R (2004) Solid State Commun 130:445

Schneider JM, Sigumonrong DP, Music D, Walter C, Emmerlich J, Iskandar R (2007) Scr Mater 57:1137

Walter C, Sigumonrong DP, El-Raghy T, Schneider JM (2006) Thin Solid Films 515:389

Walter C, Martines C, El-Raghy T, Schneider JM (2005) Steel Res Int 76:225

Lin ZJ, Zhou YC, Li MS, Wang JY (2005) Z Metallkd 96:291

Lin ZJ, Zhuo MJ, Zhou YC, Li MS, Wang JY (2006) J Appl Phys 99:076109

Lin ZJ, Li MS, Wang JY, Zhou YC (2007) Acta Mater 55:6182

Sun ZM, Ahuja R, Li S, Schneider JM (2003) Appl Phys Lett 83:899

Sun ZM, Li S, Ahuja R, Schneider JM (2004) Solid State Commun 129:589

Wang JY, Zhou YC (2004) Phys Rev B 69:244111-1

Wang JY, Zhou YC, Lin ZJ, Meng FL, Li F (2005) Appl Phys Lett 86:101902-1

Lofland SE, Hettinger JD, Harrell K, Finkel P, Gupta S, Barsoum MW, Hug G (2004) Appl Phys Lett 84:508

Tian WB, Wang PL, Zhang GJ, Kan YM, Li YX, Yan DS (2006) Scr Mater 54:841

Tian WB, Wang PL, Kan YM, Zhang GJ (2008) J Mater Sci 43:2785. doi:https://doi.org/10.1007/s10853-008-2516-2

Tian WB, Wang PL, Zhang GJ, Kan YM, Li YX (2007) J Am Ceram Soc 90:1663

Radovic M, Barsoum MW, El-Raghy T, Wiederhorn SM, Luecke WE (2002) Acta Mater 50:1297

Barsoum MW, Zhen T, Kalidindi SR, Radovic M, Murugaiah A (2003) Nature Mater 2:107

Zhen T, Barsoum MW, Kalidindi SR (2005) Acta Mater 53:4163

Sun ZM, Zhang ZF, Hashimoto H, Abe T (2002) Mater Trans 43:432

Johnston WG, Gilman JJ (1959) J Appl Phys 30:129

Courtney TH (1990) Mechanical behavior of materials. McGraw-Hill Publishing Company, New York

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Tian, W., Sun, Z., Hashimoto, H. et al. Compressive deformation behavior of ternary compound Cr2AlC. J Mater Sci 44, 102–107 (2009). https://doi.org/10.1007/s10853-008-3113-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-008-3113-0