Abstract

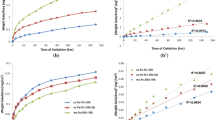

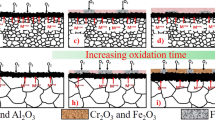

Nanocrystalline (nc) and microcrystalline (mc) Fe10Cr alloys were prepared by high energy ball-milling followed by compaction and sintering, and then oxidized in air for 52 h at 400 °C. The oxidation resistance of nc Fe10Cr alloy as determined by measuring the weight gain after regular time intervals was compared with that of the mc alloy of same chemical composition (also prepared by the same fabrication route and oxidized under identical conditions). Oxidation resistance of nc Fe10Cr alloy was found to be in excess of an order of magnitude superior than that of mc Fe10Cr alloy. This article also presents results of secondary ion mass spectrometry (SIMS) of oxidized samples of nc and mc Fe–Cr alloys, evidencing the formation of a more protective oxide scale in the nc alloy.

Similar content being viewed by others

References

Koch CC, Youssef KM, Scattergood RO, Murty KL (2005) Adv Eng Mater 7:787

Gleiter H (1989) Prog Mater Sci 33:223

Trapp S, Limbach CT, Gonser U, Campbell SJ, Gleiter H (1995) Phys Rev Lett 75:3760

Roy RA, Roy R (1984) Mater Res Bull 19:169

Cheng S, Ma E, Wang YM, Kecskes LJ, Youssef KM, Koch CC, Trociewitz UP, Han K (2005) Acta Mater 53:1521

Youssef KM, Scattergood RO, Murty KL, Horton JA, Koch CC (2005) Appl Phys Lett 87:1

Youssef KM, Scattergood RO, Murty KL, Koch CC (2006) Scripta Mater 54:251

Groza JR (2007) In: Koch CC (ed) Nanostrucutued materials: processing, properties and applications. William Andrew Pub, Norwich, NY

Youssef KM, Scattergood RO, Murty KL, Koch CC (2004) Appl Phys Lett 85:929

Kedim OE, Cao HS, Guay D (2002) J Mater Process Technol 121:383

Rawers J, Biancaniello F, Jiggetts R, Fields R, Williams M (1999) Scripta Mater 40:277

Guruswamy S, RL M, Srisukhumbowornchai N, Michael KM, Joseph P (2000) IEEE Trans 36:3219

Siegel RW (1997) Mater Sci Forum 235–238:851

Palumbo G, Thorpe SJ, Aust KT (1990) Scripta Metall Mater 24:2347

Zhao YH, Sheng HW, Lu K (2001) Acta Mater 49:265

Chen D (1995) Mater Sci Eng A 190:193

Wang ZB, Tao NR, Tong WP, Lu J, Lu K (2003) Acta Mater 51:4319

Wang ZB, Tao NR, Tong WP, Lu J, Lu K (1996) Defect Diffus Forum 249:147

Tong HY, Shi FG, Lavernia EJ (1995) Scripta Metall Mater 32:511

Liu L, Li Y, Wang F (2008) Mater Lett 62:4081

Zhang XY, Shi MH, Li C, Liu NF, Wei YM (2007) Mater Sci Eng A 448:259

Zheng HZ, Lu SQ, Dong XJ, Ouyang DL (2008) Mater Sci Eng A 496:524

Niu Y, Cao ZQ, Gesmundo F, Farne G, Randi G, Wang CL (2003) Corros Sci 45:1125

Hossain MK (1979) Corros Sci 19:1031

Singh Raman RK (1998) Metall Mater Trans A 28A:577

Singh Raman RK (1995) Metall Mater Trans A 26A:1847

Wood GC (1961) Corros Sci 2:173

Giggins CS, Pettit FS (1969) Trans TMS-AIME 245:2509

Kofstad P (1988) High temperature corrosion. Elsevier Applied Science & Publishers Ltd., New York

Baer RD, Merz MD (1980) Metall Trans 11A:1973

Trindade VB, Krupp U, Hanjari BZ, Yang S, Christ H (2005) Mater Res 8:371

Keijser THd, Langford JI, Mittemeijer EJ, Vogels ABP (1982) J Appl Crystallogr 15:308

Singh Raman RK, Tyagi AK (1994) Mater Sci Eng A 185:97

Rees EE, McPhail DS, Ryan MP, Kelly J, Dowsett MG (2003) Appl Surf Sci 203–204:660

Ehlers J, Young DJ, Smaardijik EJ, Tyagi AK, Penkalla HJ, Singheiser L, Quadakkers WJ (2006) Corros Sci 48:3428

Wagner CJ (1952) Electrochem Soc 99:369; 103:571 (1956)

Wagner C (1965) Corros Sci 5:751

Acknowledgements

The authors acknowledge support of Australian Research Council (ARC) with a grant (DP0665112) to carry out this study, under their Discovery grant scheme. The authors are also thankful to the support of Australian Institute of Nuclear Science and Engineering (AINSE) for carrying out the SIMS work.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Gupta, R.K., Singh Raman, R.K. & Koch, C.C. Fabrication and oxidation resistance of nanocrystalline Fe10Cr alloy. J Mater Sci 45, 4884–4888 (2010). https://doi.org/10.1007/s10853-010-4665-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-010-4665-3