Abstract

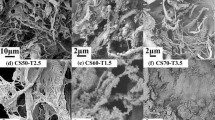

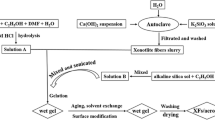

Short (<2.5 mm) cellulose fiber–silica composite aerogels were synthesized by dispersing cellulose fibers in polyethoxydisiloxane-based sol. After in situ gelation, silica phase was hydrophobized with hexamethyldisilazane, and the composites were dried either at ambient pressure or with supercritical (sc) CO2. Fiber concentration was varied from 0 to 25 wt% (corresponding to 0–2.1 vol%) of the final dried composite. Preformed cellulosic fiber network preserved the monolithic shape of the silica-based composites during ambient drying. At room conditions, thermal conductivities were 0.015 ± 0.001 W/(m K) for sc-dried aerogels and 0.017 ± 0.001 W/(m K) for their ambient-dried counterparts. Materials dried with either method exhibited large specific surface areas, from 570 to 730 m2/g, and SEM analysis did not show significant differences in the global structure of the silica network. Composite aerogels were hydrophobic with water contact angles around 138°. Based on this proof of concept, the same approach was used with a variety of natural and recycled cellulosic fibers also resulting in silica-based monoliths with low thermal conductivities in the 0.016–0.023 W/(m K) range, all produced via ambient drying.

Similar content being viewed by others

References

Hrubesh LW (1998) Aerogel applications. J Non-Cryst Solids 225:335–342

Fricke J, Lu X, Wang P, Büttner D, Heinemann U (1992) Optimization of monolithic silica aerogel insulants. Int J Heat Mass Tran 35(9):2305–2309

Pierre AC, Rigacci A (2011) SiO2 aerogels. In: Aegerter MA, Leventis N, Koebel MM (eds) Aerogels handbook. Springer, New York

Baetens R, Jelle BP, Gustavsen A (2001) Aerogel insulation for building applications: a state-of-the-art review. Energ Build 43:761–769

Koebel M, Rigacci A, Achard P (2012) Aerogel-based thermal superinsulation: an overview. J Sol Gel Sci Technol 63:315–339

Jelle BP (2011) Traditional, state-of-the-art and future thermal building insulation materials and solutions—properties, requirements and possibilities. Energ Build 43:2549–2563

Cuce E, Cuce PM, Wood CJ, Riffat SB (2014) Toward aerogel based thermal superinsulation in buildings: a comprehensive review. Renew Sustain Energy Rev 34:273–299

Zeng SQ, Hunt AJ, Cao W, Greif R (1994) Pore size distribution and apparent gas thermal conductivity of silica aerogel. J Heat Trans-T ASME 116:756–759

Notario B, Pinto J, Solorzano E, de Saja JA, Dumon M, Rodriguez-Perez MA (2015) Experimental validation of the Knudsen effect in nanocellular polymeric foams. Polymer 56:57–67

Caps R, Fricke J (1985) Determination of the radiative heat transfer in transparent silica aerogel. Int J Sol Energ 3(1):13–18

Bisson A, Rigacci A, Lecomte D, Rodier E, Achard P (2003) Drying of silica gels to obtain aerogels: phenomenology and basic techniques. Dry Technol 21(4):593–628

Tewari PH, Hunt AJ, Lofftus KD (1985) Ambient-temperature supercritical drying of transparent silica aerogels. Matter Lett 3(9–10):363–367

Smith DM, Deshpande R, Brinke CJ (1992) Preparation of low-density aerogels at ambient pressure. MRS Symp Proc 271:567–572

Schwertfeger F, Frank D, Schmidt M (1998) Hydrophobic waterglass based aerogels without solvent exchange or supercritical drying. J Non Cryst Solids 225:24–29

Wang LJ, Zhao SY, Yang M (2009) Structural characteristics and thermal conductivity of ambient pressure dried silica aerogels with one-step solvent exchange/surface modification. J Mater Chem Phys 113:485–490

Mahadik DB, Rao AV, Kumar R, Ingale SV, Wagh PB, Gupta SC (2012) Reduction of processing time by mechanical shaking of ambient pressure dried TEOS based silica aerogel granules. J Porous Mater 19:87–94

Fesmire JE (2006) Aerogel insulation systems for space launch applications. Cryogenics 46:111–117

Bardy ER, Mollendorf JC, Pendergast DR (2007) Thermal conductivity and compressive strain of aerogel insulation blankets under applied hydrostatic pressure. J Heat Trans T ASME 129:232–235

Hayase G, Kanamori K, Maeno A, Kaji H, Nakanishi K (2016) Dynamic spring-back behavior in evaporative drying of polymethylsilsesquioxane monolithic gels for low-density transparent thermal superinsulators. J Non Cryst Solids 434:115–119

Einarsrud MA (1998) Light gels by conventional drying. J Non Cryst Solids 225:1–7

Maleki H, Duraes L, Portugal A (2014) An overview on silica aerogels synthesis and different mechanical reinforcing strategies. J Non Cryst Solids 385:55–74

Li L, Yalcin B, Nguyen BN, Meador MAB, Cakmak M (2009) Flexible nanofiber-reinforced aerogel (xerogel) synthesis, manufacture, and characterization. ACS Appl Mater Interfaces 1(11):2491–2501

Li X, Wang Q, Li H, Ji H, Sun X, He J (2013) Effect of sepiolite fiber on the structure and properties of the sepiolite/silica aerogel composite. J Sol Gel Sci Technol 67:646–653

Hayase G, Kanamori K, Abe K, Yano H, Maeno A, Kaji H, Nakanishi K (2013) Polymethylsilsesquioxane-cellulose nanofiber biocomposite aerogels with high thermal insulation, bendability, and superhydrophobicity. ACS Appl Mater Interfaces 6:9466–9471

Zhao S, Zhang Z, Sèbe G, Wu R, Virtudazo RVR, Tingaut P, Koebel M (2015) Multiscale assembly of superinsulating silica aerogels within silylated nanocellulosic scaffolds: improved mechanical properties promoted by nanoscale chemical compatibilization. Adv Funct Mater 25(15):2326–2334

Fu J, Wang S, He C, Lu Z, Huang J, Chen Z (2016) Facilitated fabrication of high strength silica aerogels using cellulose nanofibrils as scaffold. Carbohyd Polym 147:89–96

John MJ, Thomas S (2008) Biofibres and biocomposites. Carbohyd Polym 71:343–364

Jawaid M, Abdul Khalil HPS (2011) Cellulosic/synthetic fibre reinforced polymer hybrid composites: a review. Carbohyd Polym 86:1–18

Joshi SV, Drzal LT, Mohanty AK, Arora S (2004) Are natural fiber composites environmentally superior to glass fiber reinforced composites? Compos Part A 35:371–376

Wong JCW, Kaymak H, Tingaut P, Brunner S, Koebel MM (2015) Mechanical and thermal properties of nanofibrillated cellulose reinforced silica aerogel composites. Micropor Mesopor Mat 217:150–158

Sai H, Xing L, Xiang J, Cui L, Jiao J, Zhao C, Li Z, Li F (2013) Flexible aerogels based on an interpenetrating network of bacterial cellulose and silica by non-supercritical drying process. J Mater Chem A 1:7963–7970

Zhao S, Malfait WJ, Demilecamps A, Zhang Y, Brunner S, Huber L, Tingaut P, Rigacci A, Budtova T, Koebel MM (2015) Strong, thermally superinsulating biopolymer–silica aerogel hybrids by cogelation of silicic acid with pectin. Angew Chem Int Ed 54:14282–14286

Demilecamps A, Beauger C, Hildenbrand C, Rigacci A, Budtova T (2015) Cellulose—silica aerogels. Carbohyd Polym 122:293–300

Netravali AN, Chabba S (2003) Composites get greener. Mater Today 6(4):22–29

Masmoudi Y, Rigacci A, Ilbizian P, Cauneau F, Achard P (2006) Diffusion during the supercritical drying of silica gels. Dry Technol 24(9):1121–1125

Rudaz C, Courson R, Bonnet L, Calas-Etienne S, Sallée H, Budtova T (2014) Aeropectin: fully biomass-based mechanically strong and thermal superinsulating aerogel. Biomacromolecules 15(6):2188–2195

Yokogawa H, Yokoyama M (1995) Hydrophobic silica aerogels. J Non Cryst Solids 186:23–29

Diaz JA, Ye Z, Wu X, Moore AL, Moon RJ, Martini A, Boday DJ, Youngblood JP (2014) Thermal conductivity in nanostructured films: from single cellulose nanocrystals to bulk films. Biomacromolecules 15:4096–4101

Gupta M, Yang J, Roy C (2003) Specific heat and thermal conductivity of softwood bark and softwood char particles. Fuel 82:919–927

Sekino N (2016) Density dependence in the thermal conductivity of cellulose fiber mats and wood shavings mats: investigation of the apparent thermal conductivity of coarse pores. J Wood Sci 62:20–26

Brinker CJ, Scherer GW (1990) Sol–gel science. Academic Press, Cambridge

Li S, Lyons-Hart J, Banyasz J, Shafer K (2001) Real-time evolved gas analysis by FTIR method: an experimental study of cellulose pyrolysis. Fuel 80:1809–1817

Lin Y-C, Cho J, Tompsett GA, Westmoreland PR, Huber GW (2009) Kinetics and mechanism of cellulose pyrolysis. J Phys Chem C 113:20097–20107

Rao AP, Rao AV, Pajonk GM, Shewale PM (2007) Effect of solvent exchanging process on the preparation of the hydrophobic silica aerogels by ambient pressure drying method using sodium silicate precursor. J Mater Sci 42:8418–8425. doi:10.1007/s10853-007-1788-2

Acknowledgements

The French Agency for Environment and Energy Management (ADEME) is acknowledged for financial support. The authors are also very grateful to Lenzing, Stora Enso, and Aerocycle for providing fibers, pulps, and recycled fiber, respectively, as well as Enersens for providing PEDS solutions. The authors thank Pierre Ilbizian (MINES ParisTech–PERSEE) for sc CO2 drying, Julien Jaxel (MINES ParisTech–CEMEF) for pulp fiber preparation and TGA analysis, university of Nice for allowing us to perform TGA experiments, and Suzanne Jacomet (MINES ParisTech–CEMEF) for SEM.

Author information

Authors and Affiliations

Corresponding authors

Electronic supplementary material

Below is the link to the electronic supplementary material.

The online version of this article (doi:10.1007/s10853-016-0514-3) contains supplementary material, which is available to authorized users.

10853_2016_514_MOESM1_ESM.mp4

Supplementary material 1 (MP4 5247 kb)

Rights and permissions

About this article

Cite this article

Markevicius, G., Ladj, R., Niemeyer, P. et al. Ambient-dried thermal superinsulating monolithic silica-based aerogels with short cellulosic fibers. J Mater Sci 52, 2210–2221 (2017). https://doi.org/10.1007/s10853-016-0514-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-016-0514-3