Abstract

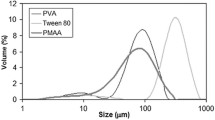

Microencapsulated phase change materials (MePCMs) based on swelling polymerization in Pickering emulsion were demonstrated. Monodisperse poly(glycidyl methacrylate-co-2-hydroxyethyl methacrylate) P(GMA-co-HEMA) particles were prepared by dispersion polymerization. The introduction of hydrophilic monomer HEMA endowed the obtained particles with suitable surface hydrophilicity for stabilizing Pickering emulsion. MePCMs with PGMA–polystyrene interpenetrating composite shell were formed when non-crosslinked particles were employed as stabilizer, while MePCMs with particles-embedded shell were prepared with crosslinked particles as Pickering stabilizer. Phase change property, thermal stability and thermal reliability of two kinds of MePCMs were investigated by TGA, FT-IR, DSC and cycling test. The temperature of 10% weight loss of MePCMs with interpenetrating shell was 11 °C higher than that of MePCMs with particles-embedded shell. After cycling test, the percentage of leached core materials from MePCMs with interpenetrating shell was approximately one-third of that from MePCMs with particles-embedded shell. The results showed that MePCMs with an integral shell presented better thermal stability, tightness and thermal reliability than MePCMs with particles-embedded shell. The research developed a simple process for MePCMs with excellent performance.

Similar content being viewed by others

References

O’Brien CJ, Foiles SM (2016) Exploration of the mechanisms of temperature-dependent grain boundary mobility: search for the common origin of ultrafast grain boundary motion. J Mater Sci 51:6607–6623. https://doi.org/10.1007/s10853-016-9944-1

Pielichowska K, Pielichowski K (2014) Phase change materials for thermal energy storage. Prog Mater Sci 65:67–123

Li H, Fang G, Liu X (2010) Synthesis of shape-stabilized paraffin/silicon dioxide composites as phase change material for thermal energy storage. J Mater Sci 45:1672–1676. https://doi.org/10.1007/s10853-009-4146-8

Yataganbaba A, Ozkahraman B, Kurtbas I (2017) Worldwide trends on encapsulation of phase change material: a bibliometric analysis (1990–2015). Appl Energy 185:720–731

Giro-Paloma J, Martínez M, Cabeza LF, Fernández AI (2016) Types, methods, techniques, and applications for microencapsulated phase change materials (MPCM): a review. Renew Sust Energy Rev 53:1059–1075

You M, Zhang X, Wang J (2009) Polyurethane foam containing microencapsulated phase-change materials with styrene–divinybenzene co-polymer shells. J Mater Sci 44:3141–3147. https://doi.org/10.1007/s10853-009-3418-7

Hassabo AG, Mohamed AL (2017) Enhancement the thermo-regulating property of cellulosic fabric using encapsulated paraffins in modified pectin. Carbohyd Polym 165:421–428

Giro-Paloma J, Barreneche C, Martínez M, Sumiga B, Fernández AI, Cabeza LF (2016) Mechanical response evaluation of microcapsules from different slurries. Renew Energy 85:732–739

Lee H, Choi C-H, Abbaspourrad A, Wesner C, Caggioni M, Zhu T, Weitz DA (2016) Encapsulation and enhanced retention of fragrance in polymer microcapsules. ACS Appl Mater Interfaces 8:4007–4013

Yin D, Ma L, Liu J, Zhang QY (2014) Pickering emulsion: a novel template for microencapsulated phase change materials with polymer-silica hybrid shell. Energy 64:575–581

Sun N, Xiao Z (2016) Paraffin wax-based phase change microencapsulation embedded with silicon nitride nanoparticles for thermal energy storage. J Mater Sci 51:8550–8561. https://doi.org/10.1007/s10853-016-0116-0

Alva G, Lin Y, Liu L, Fang GY (2017) Synthesis, characterization and applications of microencapsulated phase change materials in thermal energy storage: a review. Energy Build 144:276–294

Liu H, Gu X, Hu M, Hu Y, Wang C (2014) Facile fabrication of nanocomposite microcapsules by combining layer-by-layer self-assembly and Pickering emulsion templating. RSC Adv 4:16751–16758

Yin D, Geng W, Zhang Q, Zhang B (2015) Confining polymerization at emulsion interface by surface-initiated atom transfer radical polymerization on reactive Pickering stabilizer. J Ind Eng Chem 31:360–366

Wei W, He J, Yu B, Zou Y, Liu F, Chen X, Chen J (2016) Synthesis of microencapsulated benzyl benzoate with a CaCO3 shell and its application to the durable anti-mite finishing of nylon 6 fabric. RSC Adv 6:59624–59632

Zhang L, Yang W, Jiang Z, He F, Zhang K, Fan J, Wu J (2017) Graphene oxide-modified microencapsulated phase change materials with high encapsulation capacity and enhanced leakage-prevention performance. Appl Energy 197:354–363

Yin D, Ma L, Geng W, Zhang B, Zhang Q (2015) Microencapsulation of n-hexadecanol by in situ polymerization of melamine-formaldehyde resin in emulsion stabilized by styrene-maleic anhydride copolymer. Int J Energy Res 39:661–667

Thompson KL, Armes SP, Howse JR, Ebbens S, Ahmad I, Zaidi JH, York DW, Burdis JA (2010) Covalently cross-linked colloidosomes. Macromolecules 43:10466–10474

Thompson KL, Williams M, Armes SP (2015) Colloidosomes: synthesis, properties and applications. J Colloid Interface Sci 447:217–228

Yin D, Bai L, Jia Y, Liu J, Zhang Q (2017) Microencapsulation through thermally sintering Pickering emulsion-based colloidosomes. Soft Matter 13:3720–3725

Liu J, Yin D, Zhang S, Liu H, Zhang Q (2015) Synthesis of polymeric core/shell microspheres with spherical virus-like surface morphology by Pickering emulsion. Colloids Surf A 466:174–180

Yin D, Zhang Q, Yin C, Jia Y, Zhang H (2010) Effect of particle coverage on morphology of SiO2-covered polymer microspheres by Pickering emulsion polymerization. Colloids Surf A 367:70–75

Zhou J, Qiao X, Binks BP, Sun K, Bai M, Li Y, Liu Y (2011) Magnetic Pickering emulsions stabilized by Fe3O4 nanoparticles. Langmuir 27:3308–3316

Chevalier Y, Bolzinger MA (2013) Emulsions stabilized with solid nanoparticles: Pickering emulsions. Colloids Surf A 439:23–34

Zhou D, Zhang Z, Tang J, Zhang M, Liao L (2016) Effects of variables on the dispersion of cationic–anionic organo-montmorillonites and characteristics of Pickering emulsion. RSC Adv 6:9678–9685

Tang S, Zhang R, Liu F, Liu X (2015) Hansen solubility parameters of polyglycolic acid and interaction parameters between polyglycolic acid and solvents. Eur Polym J 72:83–88

Asai S, Majumdar S, Gupta A, Kargupta K, Ganguly S (2009) Dynamics and pattern formation in thermally induced phase separation of polymer-solvent system. Comput Mater Sci 47:193–205

Cao F, Yang B (2014) Supercooling suppression of microencapsulated phase change material by optimizing shell composition and structure. Appl Energy 113:1512–1518

Kong W, Fu X, Yuan Y, Liu Z, Lei J (2017) Preparation and thermal properties of crosslinked polyurethane/lauric acid composites as novel form stable phase change materials with a low degree of supercooling. RSC Adv 7:29554–29562

Acknowledgements

The supports from the National key research and development program of China (No. 2016YFC0301302), Natural Science Foundation of Shannxi Province (2017JM5080) and National Nature Science Foundation of China (51173147) are highly appreciated.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yin, D., Jia, Y., Chen, J. et al. Design of microencapsulated phase change material by one-step swelling polymerization in Pickering emulsion. J Mater Sci 53, 7249–7257 (2018). https://doi.org/10.1007/s10853-017-1494-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-017-1494-7