Abstract

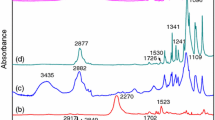

Novel binary shape-stabilized composite phase change materials (CPCMs) have been successfully prepared using a crosslinked polyurethane (PU) copolymer with a solid–solid phase transition as the supporting framework for loading additional (‘free’) poly(ethylene glycol) (PEG). The PU copolymer was synthesized by a two-step method using 2-hydroxypropyl-β-cyclodextrin (Hp-β-CD) as a chain extender and PEG as a soft segment. The composition, morphology, phase transition behavior and thermal properties of the prepared CPCMs have been elucidated by a wide range of techniques. Investigation of FTIR spectra and SEM images reveal that the ‘free’ PEG and the PU copolymer network within the CPCMs have good compatibility and high affinity due to the noncovalent interactions. Polarized light optical microscopy shows that the CPCMs produce smaller spherulites than pristine PEG, and homogeneous nucleation was prevalent during the crystallization process. Due to the dual-phase transition of the CPCMs (the solid–liquid phase transition of ‘free’ PEG and solid–solid phase transition of the PU matrix) occurring within the same, narrow temperature window, the CPCMs have far higher heat storage density compared with that of traditional shape-stabilized PCMs with the same ‘free’ PEG content. Importantly, thermal cycling and thermogravimetric analyses show that the CPCMs have good reusability and excellent thermal stability for potential use in thermoregulation or energy storage applications.

Similar content being viewed by others

References

Abhat A (1983) Low temperature latent heat thermal energy storage: heat storage materials. Sol Energy 30:313–332

Khudhair AM, Farid MM (2004) A review on energy conservation in building applications with thermal storage by latent heat using phase change materials. Energy Convers Manag 45:263–275

Zhang P, Xiao X, Ma ZW (2016) A review of the composite phase change materials: fabrication, characterization, mathematical modeling and application to performance enhancement. Appl Energy 165:472–510

Kenisarin M, Mahkamov K (2007) Solar energy storage using phase change materials. Renew Sust Energy Rev 11:1913–1965

Pielichowska K, Pielichowski K (2014) Phase change materials for thermal energy storage. Prog Mater Sci 65:67–123

Zhou D, Zhao CY, Tian Y (2012) Review on thermal energy storage with phase change materials (PCMs) in building applications. Appl Energy 92:593–605

Oró E, de Gracia A, Castell A, Farid MM, Cabeza LF (2012) Review on phase change materials (PCMs) for cold thermal energy storage applications. Appl Energy 99:513–533

Jacob R, Bruno F (2015) Review on shell materials used in the encapsulation of phase change materials for high temperature thermal energy storage. Renew Sust Energy Rev 48:79–87

Mehrali M, Latibari ST, Rosen MA, Akhiani AR, Naghavi MS, Sadeghinezhad E, Metselaar HSC, Nejad MM, Mehrali M (2016) From rice husk to high performance shape stabilized phase change materials for thermal energy storage. RSC Adv 6:45595–45604

Latibari ST, Mehrali M, Mehrali M, Afifi ABM, Mahlia TMI, Akhiani AR, Metselaar HSC (2015) Facile synthesis and thermal performances of stearic acid/titania core/shell nanocapsules by sol-gel method. Energy 85:635–644

Wu Y, Chen C, Jia Y, Wu J, Huang Y, Wang L (2018) Review on electrospun ultrafine phase change fibers (PCFs) for thermal energy storage. Appl Energy 210:167–181

Sarı A, Karaipekli A (2009) Preparation, thermal properties and thermal reliability of palmitic acid/expanded graphite composite as form-stable PCM for thermal energy storage. Sol Energy Mater Sol Cells 93:571–576

Wang C, Feng L, Li W, Zheng J, Tian W, Li X (2012) Shape-stabilized phase change materials based on polyethylene glycol/porous carbon composite: the influence of the pore structure of the carbon materials. Sol Energy Mater Sol Cells 105:21–26

Kholmanov I, Kim J, Ou E, Ruoff RS, Shi L (2015) Continuous carbon nanotube-ultrathin graphite hybrid foams for increased thermal conductivity and suppressed subcooling in composite phase change materials. ACS Nano 9:11699–11707

Xia Y, Cui W, Zhang H, Xu F, Sun L, Zou Y, Chu H, Yan E (2017) Synthesis of three-dimensional graphene aerogel encapsulated n-octadecane for enhancing phase- change behavior and thermal conductivity. J Mater Chem A 5:15191–15199

Qi GQ, Liang CL, Bao RY, Liu ZY, Yang W, Xie BH, Yang MB (2014) Polyethylene glycol based shape-stabilized phase change material for thermal energy storage with ultra-low content of graphene oxide. Sol Energy Mater Sol Cells 123:171–177

Fang G, Li H, Chen Z, Liu X (2011) Preparation and properties of palmitic acid/SiO2 composites with flame retardant as thermal energy storage materials. Sol Energy Mater Sol Cells 95:1875–1881

Sarı A, Biçer A (2012) Thermal energy storage properties and thermal reliability of some fatty acid esters/building material composites as novel form-stable PCMs. Sol Energy Mater Sol Cells 101:114–122

Liang XH, Guo YQ, Gu LZ, Ding EY (1995) Crystalline-amorphous phase transition of poly(ethylene glycol)/cellulose blend. Macromolecules 28:6551–6555

Chen C, Wang L, Huang Y (2011) Electrospun phase change fibers based on polyethylene glycol/cellulose acetate blends. Appl Energy 88:3133–3139

Wang L, Meng D (2010) Fatty acid eutectic/polymethyl methacrylate composite as form-stable phase change material for thermal energy storage. Appl Energy 87:2660–2665

Mu M, Basheer PAM, Sha W, Bai Y, McNally T (2016) Shape stabilised phase change materials based on a high melt viscosity HDPE and paraffin waxes. Appl Energy 162:68–82

Chen C, Liu K, Wang H, Liu W, Zhang H (2013) Morphology and performances of electrospun polyethylene glycol/poly (dl-lactide) phase change ultrafine fibers for thermal energy storage. Sol Energy Mater Sol Cells 117:372–381

Hu W, Yu X (2012) Encapsulation of bio-based PCM with coaxial electrospun ultrafine fibers. RSC Adv 2:5580–5584

Chen Z, Wang J, Yu F, Zhang Z, Gao X (2015) Preparation and properties of graphene oxide-modified poly(melamine-formaldehyde) microcapsules containing phase change material n-dodecanol for thermal energy storage. J Mater Chem A 3:11624–11630

Chen C, Liu W, Wang Z, Peng K, Pan W, Xie Q (2015) Novel form stable phase change materials based on the composites of polyethylene glycol/polymeric solid-solid phase change material. Sol Energy Mater Sol Cells 134:80–88

Tang B, Wang L, Xu Y, Xiu J, Zhang S (2016) Hexadecanol/phase change polyurethane composite as form-stable phase change material for thermal energy storage. Sol Energy Mater Sol Cells 144:1–6

Zhang Y, Wang L, Tang B, Lu R, Zhang S (2016) Form-stable phase change materials with high phase change enthalpy from the composite of paraffin and cross-linking phase change structure. Appl Energy 184:241–246

Liu Z, Wu B, Fu X, Yan P, Yuan Y, Zhou C, Lei J (2017) Two components based polyethylene glycol/thermosetting solid-solid phase change material composites as novel form stable phase change materials for flexible thermal energy storage application. Sol Energy Mater Sol Cells 170:197–204

Chen C, Liu W, Wang H, Lin K (2015) Synthesis and performances of novel solid-solid phase change materials with hexahydroxy compounds for thermal energy storage. Appl Energy 152:198–206

Peng K, Chen C, Pan W, Liu W, Wang Z, Zhu L (2016) Preparation and properties of β-cyclodextrin/4,4′-diphenylmethane diisocyanate/polyethylene glycol (β-CD/MDI/PEG) crosslinking copolymers as polymeric solid-solid phase change materials. Sol Energy Mater Sol Cells 145:238–247

Chen C, Liu W, Wang H, Zhu L (2016) Synthesis and characterization of novel solid-solid phase change materials with a polyurethaneurea copolymer structure for thermal energy storage. RSC Adv 6:102997–103005

Narayanan G, Aguda R, Hartman M, Chung CC, Boy R, Gupta BS, Tonelli AE (2016) Fabrication and characterization of poly(ε-caprolactone)/Hp-β-cyclodextrin pseudorotaxane nanofibers. Biomacromol 17:271–279

Liu Z, Fu X, Jiang L, Wu B, Wang J, Lei J (2016) Solvent-free synthesis and properties of novel solid-solid phase change materials with biodegradable castor oil for thermal energy storage. Sol Energy Mater Sol Cells 147:177–184

Su J, Liu P (2006) A novel solid-solid phase change heat storage material with polyurethane block copolymer structure. Energy Convers Manag 47:3185–3191

Acknowledgements

The authors thank the financial support from National Natural Science Foundation of China (Nos. 21404061 and 21506065), the National Key R&D Program of China (No. 2017YFC11050003), Guangdong Innovative and Entrepreneurial Research Team Program (No. 2016ZT06C322), the key Project of Hunan Provincial Department of Education (17A199), and Scientific Research Foundation of Xiangnan University for High-Level Talents. PDT also thanks the State Administration for Foreign Experts Affairs and the Royal Society of Chemistry for a Visiting Researcher Program grant to China.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest exists.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Chen, C., Chen, J., Jia, Y. et al. Binary shape-stabilized phase change materials based on poly(ethylene glycol)/polyurethane composite with dual-phase transition. J Mater Sci 53, 16539–16556 (2018). https://doi.org/10.1007/s10853-018-2806-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-018-2806-2