Abstract

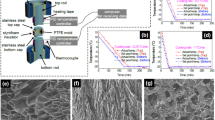

PLLA scaffolds were successfully fabricated using liquid–liquid phase separation with freeze extraction techniques. The effects of different processing conditions, such as method of cooling (direct quenching and pre-quenching), freezing temperature (−80°C and −196°C) and polymer concentration (3, 5 and 7 wt%) were investigated in relations to the scaffold morphology. SEM micrographs of scaffolds showed interconnected porous network with pore size ranging from 20 to 60 μm. The scaffolds had porosity values ranging from 80 to 90%. Changes to the interconnected network, porosity and pore size were observed when the method of cooling and polymer concentration was changed. Direct quenching to −80°C gave a more porous interconnected microstructure with uniform pore size compared to samples prepared using pre-quenching method. Larger pores were observed for samples quenched at −80°C compared to −196°C. Scaffolds prepared using direct quenching to −196°C had higher elastic modulus and compressive stress compared to those quenched to −80°C. The compressive elastic modulus ranged from 4 to 7 MPa and compressive stress at 10% strain was from 0.13 to 0.18 MPa.

Similar content being viewed by others

References

J.H. Lee et al., Biomaterials 24(16), 2773–2778 (2003)

P.X. Ma, Materials Today 7(5), 30–40 (2004)

Y. Cao et al., in Biopolymer Methods in Tissue Engineering, ed. by A.P. Hollander, P.V. Hatton (Humana Press, 2004), pp. 87–111

D.L. Butler, S.A. Goldstein, F. Guilak, J Biomech Eng 122(6), 570–575 (2000)

R. Thomson et al., in Biopolymers II, ed by N.A. Peppas, R.S. Langer (Springer Berlin/Heidelberg, 1995), pp. 245–274

L.D. Harris, B.-S. Kim, D.J. Mooney, J Biomed Mater Res 42(3), 396–402 (1998)

A.G. Mikos et al., J Biomed Mater Res 27(2), 183–189 (1993)

H.-R. Lin et al., J Biomed Mater Res 63(3), 271–279 (2002)

Y.S. Nam, T.G. Park, J Biomed Mater Res 47(1), 8–17 (1999)

S.S. Kim, D.R. Lloyd, Polymer 33(5), 1047–1057 (1992)

C. Schugens et al., Polymer 37(6), 1027–1038 (1996)

S. Yang et al., Tissue Eng 7(6), 679–689 (2001)

A.G. Mikos, J.S. Temenoff, Electron J Biotechnol 3(2), 114–119 (2000)

R. Zhang, P. X. Ma in Methods of tissue engineering, ed. by A. Atala, R.P. Lanza (Academic Press, 2002), pp. 715–724

F.J. Hua, T.G. Park et al., Polymer 44(6), 1911–1920 (2003)

F.J. Hua, G.E. Kim et al., J Biomed Mater Res 63(2), 161–167 (2002)

C. Tu et al., Polym Advan Technol 14(8), 565–573 (2003)

M.H. Ho, P. Kuo, H. Hsieh, T. Hsien, L. Hou, J. Lai, D. Wang, Biomaterials 25(1), 129–138 (2004)

Y.Q. Goh, C.P. Ooi, J Mater Sci Mater Med 19(6), 2445–2452 (2008)

A.G. Mikos et al., Polymer 35(5), 1068–1077 (1994)

P.X. Ma, R. Zhang, J Biomed Mater Res 56(4), 469–477 (2001)

Y. Wan et al., Polym Advan Technol 19(2), 114–123 (2008)

P.v.d. Witte et al., J Polym Sci Part B Polym Phys 34(15), 2553–2568 (1996)

Y. Hu et al., J Biomed Mater Res 59(3), 563–572 (2002)

S. Li et al., Polymer Int 53(12), 2079–2085 (2004)

L. Liu et al., J Biomed Mater Res 82A(3), 618–629 (2007)

N. Rotter et al., J Tissue Eng Regenerative Med 1(6), 411–416 (2007)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Budyanto, L., Goh, Y.Q. & Ooi, C.P. Fabrication of porous poly(L-lactide) (PLLA) scaffolds for tissue engineering using liquid–liquid phase separation and freeze extraction. J Mater Sci: Mater Med 20, 105–111 (2009). https://doi.org/10.1007/s10856-008-3545-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10856-008-3545-8