Abstract

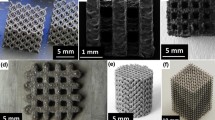

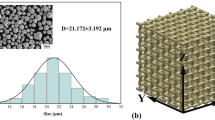

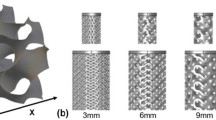

Porous structures are used in orthopaedics to promote biological fixation between metal implant and host bone. In order to achieve rapid and high volumes of bone ingrowth the structures must be manufactured from a biocompatible material and possess high interconnected porosities, pore sizes between 100 and 700 μm and mechanical strengths that withstand the anticipated biomechanical loads. The challenge is to develop a manufacturing process that can cost effectively produce structures that meet these requirements. The research presented in this paper describes the development of a ‘beam overlap’ technique for manufacturing porous structures in commercially pure titanium using the Selective Laser Melting (SLM) rapid manufacturing technique. A candidate bone ingrowth structure (71% porosity, 440 μm mean pore diameter and 70 MPa compression strength) was produced and used to manufacture a final shape orthopaedic component. These results suggest that SLM beam overlap is a promising technique for manufacturing final shape functional bone ingrowth materials.

Similar content being viewed by others

References

Mont MA, Hungerford DS. Proximally coated ingrowth prostheses. A review. Clin Orthop Relat Res. 1997;344:139–49.

Crowninshield RD, Brand RA, Pedersen DR. A stress analysis of acetabular reconstruction in protrusio acetabuli. J Bone Joint Surg. 1983;65:495–9.

Della Valle CJ, Berger RA, Shott S, Rosenberg AG, Jacobs JJ, Quigley L, et al. Primary total hip arthroplasty with a porous-coated acetabular component. A concise follow-up of a previous report. J Bone Joint Surg. 2004;86-A:1217–22.

Engh CA, Hopper RH Jr. The Odyssey of porous-coated fixation. J Arthroplasty. 2002;17:102–7. doi:10.1054/arth.2002.32547.

McCutchen JW, Collier JP, Mayor MB. Osseointegration of titanium implants in total hip arthroplasty. Clin Orthop Relat Res.. 1990;261:114–25.

Petersen MB, Poulsen IH, Thomsen J, Solgaard S. The hemispherical harris-galante acetabular cup, inserted without cement. The results of an eight to eleven-year follow-up of one hundred and sixty-eight hips. J Bone Joint Surg. 1999;81:219–24.

Rodriguez JA. Acetabular fixation options: notes from the other side. J Arthroplasty. 2006;21:93–6. doi:10.1016/j.arth.2006.02.152.

Georgette FS, Davidson JA. The effect of HIPing on the fatigue and tensile strength of a case, porous-coated Co-Cr-Mo alloy. J Biomed Mater Res. 2004;20:1229–48.

Manley MT, Kotzar G, Stern LS, Wilde A. Effects of repetitive loading on the integrity of porous coatings. Clin Orthop Relat Res. 1987;217:293–302.

Hamman G. In: Lemons JE, editor. Quantitative characterization and performance of porous implants for hard tissue applications ASTM STP 953. Philadelphia: ASTM; 1987. p. 77.

Bobyn JDPD, Pilliar RMPD, Cameron HUMD, Weatherly GCPD. The optimum pore size for the fixation of porous-surfaced metal implants by the ingrowth of bone. Clin Orthop Relat Res. 1980;150:263–70.

Bobyn J, Stackpool G, Toh K-K, Hacking S, Tanzer M, Krygier J. Bone ingrowth characteristics and interface mechanics of a new porous tantalum biomaterial. J Bone Joint Surg. 1999;81-B:907–14. doi:10.1302/0301-620X.81B5.9283.

Bobyn J, Toh K, Hacking S, Tanzer M, Krygier J. Tissue response to porous tantalum acetabular cups: a canine model. J Arthroplasty. 1999;13:347–54. doi:10.1016/S0883-5403(99)90062-1.

Gruen TA, Poggie RA, Lewallen DG, Hanssen AD, Lewis RJ, O’Keefe TJ, et al. Radiographic evaluation of a mono-block acetabular component. J Arthroplasty. 2005;20:369–78. doi:10.1016/j.arth.2004.12.049.

Ward LP, Strafford KN, Wilks TP, Subramanian C. The roll of refractory element based coating on the tribological and biological behavior of orthopaedic implants. J Mater Process Technol. 1996;56:364–74. doi:10.1016/0924-0136(95)01850-6.

Santos EC, Osakada K, Shiomi M, Kitamura Y, Abe F. Microstructure and mechanical properties of pure titanium models fabricated by selective laser melting. Proc Inst Mech Eng Part C J Mech Eng Sci. 2004;218:711–9.

Arcella FG, Abbott DH, House MA. Rapid laser forming of titanium structures. Grenada, Spain: Metallurgy World Conference; 1998.

Gerbhardt A. Rapid prototyping. Munich: Hanser publishers; 2003.

Householder R. Molding process, US, 1979.

Hopkinson N, Dickens PM. Emerging rapid manufacturing processes. In: Hopkinson N, Hague RJM, Dickens PM, editors. Rapid manufacturing: an industrial revolution for the digital age. USA: John Wiley & sons; 2006.

Chua CK, Leong KF, Lim CS. Powder-based rapid prototyping systems. In: Rapid prototyping: principles and applications. Singapore: World Scientific; 2003.

Keicher DM, Love JW, Dullea KJ, Bullen JL, Gorman PH, Smith ME. Forming structures from CAD solid models. US Patent; 2004.

Abbott DH, Arcella FG. Aeromet implementing novel Ti process. Met Powder Rep. 1998;53:24–6.

Abe F, Osakada K, Kitamura Y, Matsumoto M, Shiomi M. Manufacturing of titanium parts for medical purposes by selective laser melting. In: Rapid prototyping. Tokyo, Japan: University of Dayton; 2000. p. 288–293.

Hollander DA, von Walter M, Wirtz T, Sellei R, Schmidt-Rohlfing B, Paar O, et al. Structural, mechanical and in vitro characterization of individually structured Ti–6Al–4V produced by direct laser forming. Biomaterials. 2006;27:955–63. doi:10.1016/j.biomaterials.2005.07.041.

Sercombe T, Jones N, Day R, Kop A. Heat treatment of Ti-6Al-7Nb components produced by selective laser melting. Rapid Prototyping J. 2008;14:300–4. doi:10.1108/13552540810907974.

Hulbert SF, Klawitter JJ, Talbert CD, Fitts CT. Research in dental and medical materials. New York: Plenum; 1969. p. 19.

Nilles JL, Coletti JM, Wilson C. Biomechanical evaluation of bone porous material interfaces. J Biomed Mater Res. 1973;7:231–51. doi:10.1002/jbm.820070211.

Harris WH, Jasty M. Bone ingrowth into porous coated canine acetabular replacements: the effect of pore size, apposition, and dislocation. Hip. 1985;214–34.

Assad M, Jarzem P, Leroux MA, Coillard C, Chernyshov AV, Charette S, et al. Porous titanium-nickel for intervertebral fusion in a sheep model: part 1. Histomorphometric and radiological analysis. J Biomed Mater Res Appl Biomater. 2003;64B:107–20.

Kusakabe H, Sakamaki T, Nihei K, Oyama Y, Yanagimoto S, Ichimiya M, et al. Osseointegration of a hydroxyapatite-coated multilayered mesh stem. Biomaterials. 2004;25:2957–69. doi:10.1016/j.biomaterials.2003.09.090.

Bergmann G, Deuretzbacher G, Heller M, Graichen F, Rohlmann A, Strauss J, et al. Hip contact forces and gait patterns from routine activities. J Biomech. 2001;34:859–71. doi:10.1016/S0021-9290(01)00040-9.

Bergmann G, Graichen F, Rohlmann A. Hip joint loading during walking and running, measured in two patients. J Biomech. 1993;26:969–90. doi:10.1016/0021-9290(93)90058-M.

Dalstra M, Huiskes R. Load transfer across the pelvic bone. J Biomech. 1995;28:715–24. doi:10.1016/0021-9290(94)00125-N.

Manley MT, Ong KL, Kurtz SM. The potential for bone loss in acetabular structures following THA. Clin Orthop Relat Res. 2006;453:246–53. doi:10.1097/01.blo.0000238855.54239.fd.

Rydell NW. Forces acting in the femoral head-prosthesis. Acta Orthop Scand. 1966;Suppl 88:37.

von Eisenhart R, Adam C, Steinlechner M, Muller-Gerbl M, Eckstein F. Quantitative determination of joint incongruity and pressure distribution during simulated gait and cartilage thickness in the human hip joint. J Orthop Res. 1999;17:532–9. doi:10.1002/jor.1100170411.

Widmer KH, Zurfluh B, Morscher EW. Load transfer and fixation mode of press-fit acetabular sockets. J Arthroplasty. 2002;17:926–35. doi:10.1054/arth.2002.34526.

Dorr LD, Bloebaum R, Emmanual J, Meldrum R. Histologic, biochemical and ion analysis of tissue and fluids retrieved during total hip arthroplasty. Clin Orthop Relat Res. 1990;261:82–95.

Shanbhag AS, Jacobs JJ, Black J, Galante JO, Glant TT. Cellular mediators secreted by interfacial membranes obtained at revision total hip arthroplasty. J Arthroplasty. 1995;10:498–506.

Willert HG, Semlitsch M. Reactions of the articular capsule to wear products of artificial joint prostheses. J Biomed Mater Res. 1977;11:157–64. doi:10.1002/jbm.820110202.

Tolochko NK, Arshinov MK, Gusarov AV, Titov VI, Laoui T, Froyen L. Mechanisms of selective laser sintering and heat transfer in Ti powder. Rapid Prototyping J. 2003;9:314–26. doi:10.1108/13552540310502211.

ASTM. ASTM standard test methods of compression testing of metallic materials at room temperature. ASTM; 2000.

Gibson LJ, Ashby MF. Cellular solids: structure and properties. Cambridge, UK: Cambridge University Press; 1999.

Anselme K, Bigerelle M. Topography effects of pure titanium substrates on human osteoblast long-term adhesion. Acta Biomater. 2005;1:211–22. doi:10.1016/j.actbio.2004.11.009.

Mullen L, Stamp R, Brooks WK, Jones E, Sutcliffe C. Selective laser melting: a regular unit cell approach for the manufacture of porous titanium constructs suitable for orthopaedic application. J Biomed Mater Res. Part B. 2009 (in press).

Acknowledgements

The authors would like to thank the Engineering and Physical Sciences Research Council (EPSRC) and Stryker Orthopaedics for funding this research. Thanks also to L. Bailey for technical support.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Stamp, R., Fox, P., O’Neill, W. et al. The development of a scanning strategy for the manufacture of porous biomaterials by selective laser melting. J Mater Sci: Mater Med 20, 1839–1848 (2009). https://doi.org/10.1007/s10856-009-3763-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10856-009-3763-8