Abstract

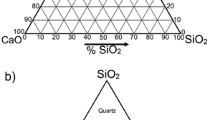

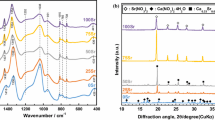

This study was concerned with the fabrication of ceramic CaO–SrO–ZnO–SiO2 spherical particles, which are novel candidates for the glass phase in glass polyalkenoate cements (GPCs). GPCs made from these glasses have potential as bone cements because, unlike conventional GPCs, they do not contain aluminum ions, which inhibit the calcification of hydroxyapatite in the body. The glass phase of GPCs require a controllable glass morphology and particle size distribution. Sol–gel processing can potentially be used to fabricate homogenous ceramic particles with controlled morphology. However, a thorough study on preparation conditions of spherical CaO–SrO–ZnO–SiO2 particles by sol–gel processing has, to date, not been reported. In this study, gels were prepared by hydrolysis and polycondensation of tetraethoxysilane (TEOS) in an aqueous solution containing polyethylene glycol and nitrates of calcium, strontium and zinc. It was possible to control the morphology and size of the gels by varying the H2O/TEOS molar ratio and the metal ion content in the starting compositions. An aliquot of 3–5 μm homogenous spherical particles were obtained at a H2O/TEOS molar ratio of 42.6 when the starting composition molar ratios were Sr(NO3):Ca(NO3)2:Zn(NO3)2:Si(OC2H5)4 = x:0.12:(0.40 − x):0.48 (0 ≤ x ≤ 0.8). Starting composition limitations are caused by the low solubility of strontium ions in the minimal amount of water used and the acceleration of hydrolysis as well as polycondensation at higher water content.

Similar content being viewed by others

References

Nicholson JW. Chemistry of glass-ionomer cements: a review. Biomaterials. 1998;19:485–94. doi:10.1016/S0142-9612(97)00128-2.

Akinmade A, Nicholson J. Glass-ionomer cements as adhesives. J Mater Sci: Mater Med. 1993;4:95–101. doi:10.1007/BF00120376.

Williams JA, Billigton RW. Changes in compressive strength of glass ionomer restorative materials with respect to time periods of 24 h to 4 months. J Oral Rehabil. 1991;18:163–8. doi:10.1111/j.1365-2842.1991.tb00044.x.

Quarles LD, Murphy G, Vogler JB, Drezner MK. Aluminum induced neo-osteogenesis: a generalized process affecting trabecular networking in the axial skeleton. J Bone Miner Res. 1990;5:625–35.

Wakayama I, Song K-J, Nerurkar VR, Yoshida S, Garruto RM. Slow dendritic transport of dissociated mouse hippocampal neurons exposed to aluminum. Brain Res. 1997;748:237–40. doi:10.1016/S0006-8993(96)01314-5.

Polizzi S, Pira E, Ferrara M, Bugiani M, Papaleo A, Albera R, et al. Neurotoxic effects of aluminium among foundry workers and Alzheimer’s disease. Neurotoxicology. 2002;23:761–74. doi:10.1016/S0161-813X(02)00097-9.

Exley C. A molecular mechanism of aluminum-induced Alzheimer’s disease? J Inorg Biochem. 1999;76:133–40. doi:10.1016/S0162-0134(99)00125-7.

Darling M, Hill R. Novel polyalkenoate (glass-ionomer) dental cements based on zinc silicate glasses. Biomaterials. 1994;15:299–306. doi:10.1016/0142-9612(94)90055-8.

Towler M, Crowley CM, Murphy D, O’Callaghan AMCA. A preliminary study of an aluminum-free glass polyalkenoate cement. J Mater Sci Lett. 2002;21:1123–6. doi:10.1023/A:1016570819402.

Boyd D, Li H, Tanner D, Towler M, Wall J. The antibacterial effects of zinc ion migration from zinc-based glass polyalkenoate cements. J Mater Sci: Mater Med. 2006;17:489–94. doi:10.1007/s10856-006-8930-6.

Guida A, Towler M, Wall JG, Hill RG, Eramo S. Preliminary work on the antibacterial effect of strontium in glass ionomer cements. J Mater Sci Lett. 2003;22:1401–3. doi:10.1023/A:1025794927195.

Boyd D, Clarkin OM, Wren AW, Towler M. Zinc-based glass polyalkenoate cements with improved setting times and mechanical properties. Acta Biomater. 2008;4:425–31. doi:10.1016/j.actbio.2007.07.010.

Kim IY, Kawachi G, Kikuta K, Cho SB, Kamitakahara M, Ohtsuki C. Preparation of bioactive spherical particles in the CaO-SiO2 system through sol-gel processing under coexistence of poly(ethylene glycol). J Eur Ceram Soc. 2008;28:1595–602.

Kim IY, Kamitakahara M, Kawachi G, Kikuta K, Cho SB, Ohtsuki C. Synthesis of ceramics in MOn/2-SiO2 system through sol-gel processing under coexistence of polyethylene glycol and in vitro evaluation of their bioactivity. J Ceram Soc Jpn. 2008;116:56–62. doi:10.2109/jcersj2.116.56.

Nakanishi K. Pore structure control of silica gels based on phase separation. J Porous Mater. 1997;4:67–112. doi:10.1023/A:1009627216939.

Nakanishi K, Komura H, Takahashi R, Soga N. Phase separation in silica sol–gel systems containing poly(ethylene oxide). I. Phase relation and gel morphology. Bull Chem Soc Jpn. 1994;67:1327–35. doi:10.1246/bcsj.67.1327.

Brinker J, Scherer GW. Sol-gel science: the physics and chemistry of sol-gel processing. San Diego: Academic press; 1990. p. 108–12.

Kim IY, Ohtsuki C, Kawachi G, Kamitakahara M, Cho SB. Preparation of bioactive microspheres of organic modified calcium silicates through sol–gel processing. J Sol-Gel Sci Technol. 2008;45:43–9. doi:10.1007/s10971-007-1634-7.

Acknowledgment

One of the authors (I.Y.K.) appreciates the support of the G-COE programme on Elucidation and Design of Materials and Molecular Functions, Nagoya University.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kim, I.Y., Towler, M.R., Wren, A. et al. Fabrication of spherical CaO–SrO–ZnO–SiO2 particles by sol–gel processing. J Mater Sci: Mater Med 20, 2267–2273 (2009). https://doi.org/10.1007/s10856-009-3790-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10856-009-3790-5