Abstract

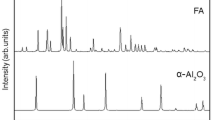

A textured calcium phosphate based bio-ceramic coating was synthesized by continuous wave Nd:YAG laser induced direct melting of hydroxyapatite precursor on Ti–6Al–4V substrate. Two different micro-textured patterns (100 μm and 200 μm line spacing) of Ca–P based phases were fabricated by this technique to understand the alignment and focal adhesion of the bone forming cells on these surfaces. X-ray diffraction studies of the coated samples indicated the presence of CaTiO3, α-Ca3(PO4)2, Ca(OH)2, TiO2 (anatase) and TiO2 (rutile) phases as a result of the intermixing between the precursor and substrate material during laser processing. A two dimensional elemental mapping of the cross-section of the coated samples exhibited the presence of higher phosphorous concentration within the coating and a thin layer of calcium concentration only at the top of the coating. Improved in vitro bioactivity and in vitro biocompatibility was observed for the laser processed samples as compared to the control.

Similar content being viewed by others

References

Palson BØ, Bhatia SN. Tissue engineering. 1st ed. Prentice Hall: Pearson; 2004. P. 252–5.

Paital SR, Dahotre NB. Calcium phosphate coatings for bio-implant applications: materials, performance factors and methodologies. Mater Sci Eng R. 2009;66:1–70.

Ji H, Ponton CB, Marquis PM. Microstructural characterization of hydroxyapatite coating on titanium. J Mater Sci Mater Med. 1992;3:283–7.

Boyd AR, Meenan BJ, Leyland NS. Surface characterization of the evolving nature of radio frequency magnetron sputter deposited calcium phosphate thin films after exposure to physiological solution. Surface Coat Technol. 2006;200:6002–13.

Haddow DB, James PF, Van Noort R. Sol-gel derived calcium phosphate coatings for biomedical applications. J Sol–Gel Sci Technol. 1998;13:261–5.

Nelea V, Ristoscu C, Chiritescu C, Ghica C, Mihailescu IN, Pelletier H, Mille P, Cornet A. Pulsed laser deposition of hydroxyapatite thin films on Ti–5Al–2.5Fe substrates with and without buffer layers. Appl Surf Sci. 2000;168:127–31.

Shirkhanzadeh M. Bioactive calcium phosphate coatings prepared by electrodeposition. J Mater Sci Lett. 1991;10:1415–7.

Kitsugi T, Nakamura T, Oka M, Senaha Y, Goto T, Shibuya T. Bone-bonding behavior of plasma sprayed coatings of BioglassR, AW-glass ceramic, and tricalcium phosphate on titanium alloy. J Biomed Mater Res. 1996;30:261–9.

Wang BC, Lee TM, Chang E, Yang CY. The shear strength and failure mode of plasma-sprayed hydroxyapatite coating to bone: the effect of coating thickness. J Biomed Mater Res. 1993;27:1315–27.

Hench LL. Bioceramics: from concept to clinic. J Am Ceram Soc. 1991;74:1487–510.

Ratner BD, Hoffman AS, Schoen FJ, Lemons JE. Biomaterials science. 2nd ed. San Diego: Elsevier; 2004.

Paital SR, Balani K, Agarwal A, Dahotre NB. Fabrication and evaluation of a pulse laser-induced Ca–P coating on a Ti alloy for bioapplication. Biomed Mater. 2009;4:1–10.

Paital SR, Dahotre NB. Wettability and kinetics of hydroxyapatite precipitation on laser textured Ca–P bioceramic coating. Acta Biomater. 2009;5:2763–72.

Paital SR, Dahotre NB. Laser surface treatment for porous and textured Ca–P bio-ceramic coating on Ti–6Al–4V. Biomed Mater. 2007;2:274–81.

Dahotre NB, Paital SR, Samant AN, Daniel C. Wetting behaviour of laser synthetic surface microtextures on Ti–6Al–4V for bioapplication. Philos Trans Roy Soc A. 2010;368:1863–89.

Yang Y, Paital SR, Dahotre NB. Effects of SiO2 substitution on wettability of laser deposited Ca–P biocoating on Ti–6Al–4V. J Mater Sci Mater Med. 2010;21:2511–21.

Lusquiños F, Pou J, Arias JL, Boutinguiza M, León B, Pérez-Amor M, Driessens FCM, Merry JC, Gibson I, Best S, Bonfield W. Production of calcium phosphate coatings on Ti–6Al–4V obtained by Nd: yttrium–alluminium–garnet laser cladding. J Appl Phys. 2001;90:4231–6.

Lusquiños F, De Carlos A, Pou J, Arias JL, Boutinguiza M, León B, Pérez-Amor M, Driessens FCM, Hing K, Gibson I, Best S, Bonfield W. Calcium phosphate coatings obtained by Nd:YAG laser cladding: physicochemical and biologic properties. J Biomed Mater Res A. 2003;64:630–7.

Lusquiños F, Pou J, Boutinguiza M, Quintero F, Soto R, León B, Pérez-Amor M. Main characteristics of calcium phosphate coatings obtained by laser cladding. Appl Surf Sci. 2005;247:486–92.

De Carlos A, Lusquiños F, Pou J, León B, Pérez-Amor M, Driessens FCM, Hing K, Best S, Bonfield W. In vitro testing of Nd:YAG laser processed calcium phosphate coatings. J Mater Sci Mater Med. 2006;17:1153–60.

Wang DG, Chen CZ, Ma J, Zhang G. In situ synthesis of hydroxyapatite coating by laser cladding. Colloids Surf B. 66:155–62.

Weidong Z, Qibin L, Min Z, Xudong W. Biocompatibility of a functionally graded bioceramic coating made by wide-band laser cladding. J Biomed Mater Res A. 2008;87:429–33.

Stevens MM, George JH. Exploring and engineering the cell surface interface. Science. 2005;310:1135–8.

Kokubo T, Kushitani H, Sakka S, Kitsugi T, Yamamuro T. Solutions able to reproduce in vivo surface-structure changes in bioactive glass ceramic A-W. J Biomed Mater Res. 1990;24(6):721–34.

Kokubo T, Takadama H. How useful is SBF in predicting in vivo bone bioactivity? Biomaterials. 2006;27(15):2907–15.

Kasemo B. Biological surface science. Surf Sci. 2002;500:656–77.

Assender H, Bliznyuk V, Porfyrakis K. How surface topography relates to materials properties. Science. 2002;297:973–6.

Paital SR, Cao Z, He W, Dahotre NB. Wetting effects on in vitro bioactivity and in vitro biocompatibility of laser micro-textured Ca–P coating. Biofabrication. 2010;2:1–14.

Wei D, Zhou Y, Jia D, Wang Y. Structure of calcium titanate/titania bioceramic composite coatings on titanium alloy and apatite deposition on their surfaces in a simulated body fluids. Surf Coat Technol. 2007;201:8715–22.

Coreño J, Coreño O. Evaluation of calcium titanate as apatite growth promoter. J Biomed Mater Res. 2005;75A:478–84.

Kunze J, Müller L, Macak JM, Greil P, Schmuki P, Müller FA. Time-dependent growth of biomimetic apatite on anodic TiO2 nanotubes. Electrochem Acta. 2008;53:6995–7003.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Paital, S.R., Bunce, N., Nandwana, P. et al. Laser surface modification for synthesis of textured bioactive and biocompatible Ca–P coatings on Ti–6Al–4V. J Mater Sci: Mater Med 22, 1393–1406 (2011). https://doi.org/10.1007/s10856-011-4321-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10856-011-4321-8