Abstract

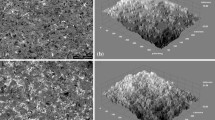

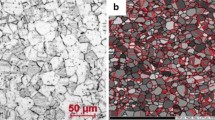

This study reports on the biocompatibility of 316 LVM steel blasted with small and rounded ZrO2 particles or larger and angular shaped Al2O3 particles. The effect of blasting on the in vitro corrosion behavior and the associated ion release is also considered. Surface of Al2O3 blasted samples was rougher than that of ZrO2 blasted samples, which was also manifested by a higher surface area. Compared to the polished alloy, blasted steels exhibited a lower corrosion resistance at the earlier stages of immersion, particularly when using Al2O3 particles. With increasing immersion time, blasted samples experienced an improvement of the corrosion resistance, achieving impedance values typical of passive alloys. Blasting of the alloy led to an increase in Fe release and the leaching of Ni, Mn, Cr and Mo. On all surfaces, ion release is higher during the first 24 h exposure and tends to decrease during the subsequent exposure time. Despite the lower corrosion resistance and higher amount of ions released, blasted alloys exhibit a good biocompatibility, as demonstrated by culturing osteoblastic cells that attached and grew on the surfaces.

Similar content being viewed by others

References

Disegi JA, Eschbach L. Stainless steel in bone surgery. Injury. 2000;31:2–6.

Sivakumar M, Dhanadurai KSK, Rajeswari S, Thulasiraman V. Failures in stainless steel orthopaedic implant devices: a survey. J Mater Sci Lett. 1995;14:351–4.

Amel-Farzad H, Peivandi MT, Yusof-Sani SMR. In-body corrosion fatigue failure of a stainless steel orthopaedic implant with a rare collection of different damage mechanisms. Eng Fail Anal. 2007;14:1205–7.

Savarino L, Maci GS, Greco M, Baldini N, Giunti A. Metal ion release from fracture fixation devices: a potential marker of implant failure. J Biomed Mater Res B Appl Biomater. 2008;86:389–95.

Jones DM, Marsh JL, Nepola JV, Jacobs JJ, Skipor AK, Urban RM, Gilbert JL, Buckwalter JA. Focal osteolysis at the junctions of a modular stainless-steel femoral intramedullary nail. J Bone Jt Surg Am. 2001;83:537–48.

French HG, Cook SD, Haddad RJ Jr. Correlation of tissue reaction to corrosion in osteosynthetic devices. J Biomed Mater Res. 1984;18:817–28.

Haynes DR, Crotti TN, Haywood MR. Corrosion of and changes in biological effects of cobalt chrome alloy and 316 L stainless steel prosthetic particles with age. J Biomed Mater Res. 2000;49:167–75.

Steinemann SG. Metal implants and surface reactions. Injury. 1996;27(Suppl3):SC16–22.

Guo HX, Lu BT, Luo JL. Interaction of mechanical and electrochemical factors in erosion-corrosion of carbon steel. Electrochim Acta. 2005;51:315–23.

Jiang XP, Wang XY, Li JX, Li DY, Man CS, Shepard MJ, Zhai T. Enhancement of fatigue and corrosion properties of pure Ti by sandblasting. Mater Sci Eng A. 2006;429:30–5.

Aparicio C, Gil FJ, Fonseca C, Barbosa M, Planell JA. Corrosion behaviour of commercially pure titanium shot blasted with different materials and sizes of shot particles for dental implant applications. Biomaterials. 2003;24:263–73.

Wennerberg A, Albrektsson T, Andersson B. Bone tissue response to commercially pure titanium implants blasted with fine and coarse particles of aluminum oxide. Int J Oral Maxillofac Implants. 1996;11:38–45.

Goldberg VM, Stevenson S, Feighan J, Davy D. Biology of grit-blasted titanium alloy implants. Clin Orthop Relat Res. 1995;319:122–9.

Aparicio C, Gil FJ, Thams U, Muñoz F, Padrós A, Planell JA. Osseointegration of grit-blasted and bioactive titanium implants: histomorphometry in minipigs. Key Eng Mater. 2001;254–256:737–40.

Bordji K, Jouzeau JY, Mainard D, Payan E, Delagoutte JP, Netter P. Evaluation of the effect of three surface treatments on the biocompatibility of 316 L stainless steel using human differentiated cells. Biomaterials. 1996;17:491–500.

Otsubo F, Kishitake K, Akiyama T, Terasaki T. Characterization of blasted austenitic stainless steel and its corrosion resistance. J Therm Spray Technol. 2003;12:555–9.

Multigner M, Frutos E, González-Carrasco JL, Jiménez JA, Marín P, Ibáñez J. Influence of the grit blasting of 316 LVM steel on the subsurface microstructure: implications on the magnetic and mechanical properties. Mater Sci Eng C. 2009;29:1357–60.

Multigner M, Ferreira S, Frutos E, Jaafar M, Ibáñez J, Marin P, Pérez-Prado T, et al. Superficial severe plastic deformation of 316 LVM stainless steel through grit blasting: effects on its microstructure and subsurface mechanical properties. Surf Coat Technol. 2010;205:1830–7.

Frutos E, Multigner M, González-Carrasco JL. Novel approaches to determine residual stresses by ultramicroindentation techniques: application to sand blasted austenitic stainless steel. Acta Mater. 2010;58:4191–8.

Boukamp BA. ‘Equivalent Circuit’ AC-Immittance Data Analysis System, Version 4.51, University of Twente, The Netherlands, 1993.

Yamamoto A, Hiromoto S. Effect of inorganic salts, amino acids and proteins on the degradation of pure magnesium in vitro. Mater Sci Eng. 2009;29:1559–68.

Guyton AC, Hall JE. Textbook of Medical Physiology, 11th Edition, Elsevier Sauders, 2006, p.292.

Mansfeld F, Wang Y. Development of ‘‘stainless’’ aluminum alloys by surface modification. Mater Sci Eng A. 1995;198:51–61.

Barsoukov E, Macdonald JR, editors. Impedance spectroscopy, theory, experiment, and aplications. 2nd ed. NJ: Wiley-Interscience; 2005.

Goodwin JE, Sage W, Tilly GP. Study of erosion by solid particles. Proc Inst Mech Eng. 1969;184:279–92.

Hao L, Lawrence J, Phua YF, Chian KS, Lim GC, Zheng HY. Enhanced human osteoblast cell adhesion and proliferation on 316 LS Stainless Steel by means of CO2 laser surface treatment. J Biomed Mater Res Part B Appl Biomater. 2005;73B:148–56.

Anselme K, Linez P, Bigerelle M, Le Maguer D, Le Maguer A, Hardouin P, Hildebrand HF, et al. The relative influence of the topography and chemistry of Ti6Al4 V surfaces on osteoblastic cell behaviour. Biomaterials. 2000;21:1567–77.

Rosa AL, Beloti MM. Effect of cpTi surface roughness on human bone marrow cell attachment, proliferation, and differentiation. Braz Dent J. 2003;14:16–21.

Saldaña L, González-Carrasco JL, Rodríguez M, Munuera L, Vilaboa N. Osteoblast response to plasma-spray porous Ti6Al4 V coating on substrates of identical alloy. J Biomed Mater Res A. 2006;77:608–17.

Kim HJ, Kim SH, Kim MS, Lee EJ, Oh HG, Oh WM, Park SW, et al. Varying Ti-6Al-4V surface roughness induces different early morphologic and molecular responses in MG63 osteoblast-like cells. J Biomed Mater Res A. 2005;74:366–73.

Anselme K, Bigerelle M. Statistical demonstration of the relative effect of surface chemistry and roughness on human osteoblast short-term adhesion. J Mater Sci Mater Med. 2006;17:471–9.

Saldaña L, Barranco V, González-Carrasco JL, Rodríguez M, Munuera L, Vilaboa N. Thermal oxidation enhances early interactions between human osteoblasts and alumina blasted Ti6Al4V alloy. J Biomed Mater Res A. 2007;81:334–46.

Misra RDK, Thein-Han WW, Pesacreta TC, Somani MC, Karjalainen LP. Biological significance of nanograined/ultrafine-grained structures: interaction with fibroblasts. Acta Biomater. 2010;6(8):3339–48.

Kunzler TP, Huwiler C, Drobek T, Vörös J, Spencer ND. Systematic study of osteoblast response to nanotopography by means of nanoparticle-density gradients. Biomaterials. 2007;28:5000–6.

Saldaña L, Barranco V, García-Alonso MC, Vallés G, Escudero ML, Munuera L, Vilaboa N. Concentration-dependent effects of titanium and aluminium ions released from thermally oxidized Ti6Al4V alloy on human osteoblasts. J Biomed Mater Res A. 2006;77:220–9.

Torralba JM, Jiménez-Morales A, Ruiz-Navas EM, Fogagnolo JB. Influence of the composition and processing conditions on the corrosion resistance of aluminium based composite materials. Bol Soc Esp Ceram V. 2002;43(2):196–9.

Mavrikakis M, Hammer B, Nørskov JK. Effect of strain on the reactivity of metal surfaces. Phys Rev Lett. 1998;81(13):2820–2.

Cigada A, Mazza B, Pedeferri P, Salvago G, Sinigaglia D, Zanini G. Stress corrosion cracking of cold-worked austenitic stainless steels. Corros Sci. 1982;22(6):559–78.

Mordyuk BN, Prokopenk GI, Vasylyev MA, Iefimov MO. Effect of structure evolution induced by ultrasonic peening on the corrosion behavior of AISI-321 stainless steel. Mater Sci Eng A. 2007;458:253–61.

Takada Y, Takahashi N, Okuno O. Electrochemical behaviour and released ions of the stainless steels used for dental magnetics attachments. In 6th International Conference on Magnetic Applications in Dentistry, March 1–20, 2007, S011.

Cieslik M, Reczynski W, Janus AM, Engvall K, Socha RP, Kotarba A. Metal release and formation of surface precipitate at stainless steel grade 316 and Hank’s solution interface-Inflammatory response and surface finisching effects. Corros Sci. 2009;51:1157–62.

Okazaki Y, Gotoh E. Comparison of metal release from various metallic biomaterials in vitro. Biomaterials. 2005;26:11–21.

Herting G, Walinder I, Leygraf C. Metal release from various grades of stainless steel exposed to synthetic body fluids. Corros Sci. 2007;49:103–11.

Reclaru L, Lüthy H, Ziegenhagen R, Eschler PY, Blatter A. Anisotropy of nickel release and corrosion in austenitic stainless steels. Acta Biomat. 2008;4:680–5.

Kanerva L, Förström L. Allergic nickel and chromate hand dermatitis induced by orthopedic metal implant. Contact Dermatitis. 2001;44:103–4.

Delescluse J, Dinet Y. Nickel allergy in Europe: the new European legislation. Dermatology. 1994;189(suppl 2):56–7.

Hanawa T. Metal ion release from metal implants. Mater Sci Eng C. 2004;24:745–52.

Acknowledgments

The authors wish to express their thanks for the financial support of Spanish’s Projects from Ministerio de Ciencia e Innovación (MAT2009-14,695-C04-02 and -04) and Fundación Mutua Madrileña. NV is supported by program I3SNS from Fondo de Investigaciones Sanitarias (Spain).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Galván, J.C., Saldaña, L., Multigner, M. et al. Grit blasting of medical stainless steel: implications on its corrosion behavior, ion release and biocompatibility. J Mater Sci: Mater Med 23, 657–666 (2012). https://doi.org/10.1007/s10856-012-4549-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10856-012-4549-y