Abstract

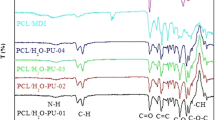

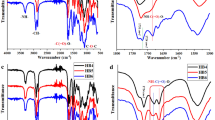

Biocompatible and biodegradable polyurethanes were prepared with fixed aliphatic diisocyanate level and varying ratios of isosorbide, and PCL diol via a simple one-shot polymerization without a catalyst. The successful synthesis of the polyurethanes was confirmed by gel permeation chromatography, 1H-nuclear magnetic resonance and Fourier transform-infrared spectroscopies and the thermal properties were determined by differential scanning calorimetry and showed glass transition temperatures of around 30–35 °C. The degradation tests were performed at 37 °C in phosphate buffer solution (approx. pH 7.3) and showed a mass loss of around 5 % after 12 weeks, except for the polymer with the highest isosorbide content which showed an initial rapid mass loss. The in vitro cytocompatibility test results following culture of osteoblasts on the polymer surface showed that relative cell number on all of the polyurethane films after 5 days of cultured on polymer films was lower compared to the proliferation rate on the optimized tissue culture plastic. These polymers offer significant promise due to the simplicity of the synthesis and the controlled degradation.

Similar content being viewed by others

References

Hollinger JO, Battistone GC. Biodegradable bone repair materials: synthetic polymers and ceramics. Clin Orthop Relat Res. 1986;207:290–305.

Kohn J, Abramson S, Langer R. In: Ratner BD, Hoffman AS, Schoen FJ, Lemons JL, editors. Biomaterials sciences an introduction to materials in medicine [chapter 2]. London: Elsevier; 2006.

Yang S, Leong K, Du Z, Chua C. The design of scaffolds for use in tissue engineering. Part I. Traditional factors. Tissue Eng. 2001;7(6):679–89.

Loh XJ, Tan YX, Li Z, Teo LS, Goh SH, Li J. Biodegradable thermogelling poly(ester urethane)s consisting of poly(lactic acid)—thermodynamics of micellization and hydrolytic degradation. Biomaterials. 2008;29:2164–72.

Rivera-Armenta JL, Heinze T, Mendoza-Martinez AM. New polyurethane foams modified with cellulose derivatives. Eur Polymer J. 2004;40:2803–12.

Tanaka H, Adachi F, Kunimura M, Kurachi K. Poly(ester-urethane)s synthesized using polyoxalate diols. Polymer Eng Sci. 2005;45:163–73.

Borkenhagen M, Stoll RC, Neuenschwander P, Suter UW, Aebischer P. In vivo performance of a new biodegradable polyester urethane system used as a nerve guidance channel. Biomaterials. 1998;19:2155–65.

Marcos-Fernandez A, Abraham GA, Valentin JL, San Roman J. Synthesis and characterization of biodegradable non-toxic poly(ester-urethane-urea)s based on poly(epsilon-caprolactone) and amino acid derivatives. Polymer. 2006;47:785–98.

Riboldi SA, Sampaolesi M, Neuenschwander P, Cossu G, Mantero S. Electrospun degradable polyester urethane membranes: potential scaffolds for skeletal muscle tissue engineering. Biomaterials. 2005;26:4606–15.

Stankus JJ, Guan JJ, Fujimoto K, Wagner WR. Microintegrating smooth muscle cells into a biodegradable, elastomeric fiber matrix. Biomaterials. 2006;27:735–44.

Loh XJ, Tan KK, Li X, Li J. The in vitro hydrolysis of poly(ester urethane)s consisting of poly[(R)-3-hydroxybutyrate] and poly(ethylene glycol). Biomaterials. 2006;27:1841–50.

Lamba MK, Woodhouse KA, Cooper SL. Polyurethanes in biomedical applications. Washington, DC: CRC Press; 1998.

Gogolewski S. Biomedical polyurethanes. In: Arshady R, editor. Desk reference of functional polymers. Syntheses and application. Am Chem Soc: Washington, DC; 1996. p. 657–698.

Sinclair TM, Kerrigan CL, Buntic R. Biodegradation of the polyurethane foam covering of breast implants. Plast Reconstr Surg. 1993;92:1003–13.

Heijkants RGJC, van Calck RV, van Tienen TG, de Groot JH, Uma PB, Pennings AJ, Veth RPH, Schouten AJ. Uncatalyzed synthesis, thermal and mechanical properties of polyurethanes based on poly(-caprolactone) and 1,4-butanediisocyanate with uniform hard segment. Biomaterials. 2005;26:4219–28.

Hassan MK, Mauritz KA, Storey RF, Wiggins JS. Biodegradable aliphatic thermoplastic polyurethane based on poly(ε-caprolactone) and l-lysinediisocyanate. J Polym Sci Polym Chem. 2006;44:2990–3000.

Izhar U, Schwalb H, Borman JB, Hellener GR, Hotoveli-Salomon A, Marom G, Stern T, Cohn D. Novel synthetic selectively degradable vascular prostheses: a preliminary implantation study. J Surg Res. 2001;95:152–60.

Gorna K, Gogolewski S. Biodegradable polyurethanes for implants. II. Invitro degradation and calcification of materials from poly(ε-caprolactone)–poly(ethyleneoxide) diols and various chain extenders. J Biomed Mater Res. 2002;60:592–606.

Cohn D, Stern T, Gonzalez MF. EpsteinJ. biodegradable poly(ethyleneoxide)/poly(ε-caprolactone) multiblock copolymers. J Biomed Mater Res. 2002;59:273–81.

Saad GR, Lee YJ, Seliger H. Synthesis and characterization of biodegradable poly(ester-urethanes) based on bacterial poly(R-3-hydroxybutyrate). J Appl Polym Sci. 2002;83:703–18.

Gorna K, Gogolewski S. Novel biodegradable polyurethanes for medical applications. In: Agrawal CM, Parr JE, Lin ST, editors. Synthetic bioresorbable polymers for implants. ASTM STP 1396. West Conshohocken: American Society for Testing and Material and Materials; 2000. p. 39–57.

Skarja GA, Woodhouse KA. Structure-property relationships of degradable polyurethane elastomers containing an amino acid-based chain extender. J Appl Polym Sci. 2000;75:1522–34.

Fenouillot AF, Rousseau G, Colomines R, et al. Polymers from renewable 1, 4: 3, 6-dianhydrohexitols(isosorbide, isomannide and isoidide): a review. Prog Polym Sci. 2010;35:578–622.

Kricheldorf HR. ‘‘Sugar diols’’ as building blocks of polycondensates. Polym Rev. 1997;37:599–631.

Noordover BAJ, Duchateau R, van Benthem RATM, et al. Enhancing the functionality of biobased polyestercoating resins through modification with citric acid. Biomacromolecules. 2007;8:3860–70.

Noordover BAJ, van Staalduinen VG, Duchateau R, et al. Co- and terpolyesters based on isosorbide and succinic acid for coating applications: synthesis and characterization. Biomacromolecules. 2006;7:3406–16.

Bourbonnais G. Les molecules de la vie: Les glucides. London: Chapman and Hill; 2003. p. 67–83.

Tamion R, Marsais F, Ribereau P. Quequiner. Asymmetric synthesis with new chiral auxiliaries derived from isosorbide. Tetrahedron: Asymmetry. 1993;4:2415–8.

Kumar S, Ramachandran U. The synthesis and applications of asymmetric phase-transfer catalysts derived from isomannide and isosorbide. Tetrahedron. 2005;61:4141–8.

Tamion R, Marsais F, Queguiner G. Base induced ring opening of a sugar derivative O-carbamate. Tetrahedron Lett. 1995;36:2761–4.

Besset C, Binauld S, Ibert M, et al. Copper-catalyzed vs. thermal step growth polymerization of starch derived R-azide-x-alkyne dianhydrohexitol stereoisomers: to click or not to click? Macromolecules. 2010;43:17–9.

Stoss P, Hemmer R. 1,4:3,6-Dianhydrohexitols. Adv Carbohydr Chem Biochem. 1991;49:93–173.

Malhotra SV, Kumar V, East A, Jaffe M. Applications of corn-based chemistry. Bridge-Wash-Nat Acad Eng. 2007;37:17–24.

Langer R. Biomaterials: status, challenges, and perspectives. AIChE J. 2000;46:1286–9.

Gorna K, Gogolewski S. Biodegradable porous polyurethane scaffolds for tissue repair and regeneration J Biomed Mater Res A. doi:10.1002/jbm.a.

Rivera-Armenta JL, Heinze TH, Mendoza-Martínez AM. New polyurethane foams modified with cellulose derivatives. Eur Polymer J. 2004;40:2803–12.

Hummel DO, Ellinghorst G, Khatchatryan A, Stenzenberger HD. Segmented copolyethers with urethane and urea or semicarbazide links for blood circulation systems II. Die Angewandte Makromolekulare Chemie. 1979;82:129–48.

Luo N, Wang DN, Ying SK. Hydrogen-bonding properties of segmented polyether poly(urethane urea) copolymer. Macromolecules. 1997;30:4405–9.

Yang YS, Lee LJ, Lo SKT, Menardi PJ. Monitoring the cure of unsaturated polyester resins by pressure DSC and FTIR-PLC. J Appl Polym Sci. 1989;37:2313–30.

Sarkar D, Yang JC, Gupta AS, Lopina ST. Synthesis and characterization of l-tyrosine based polyurethanes for biomaterial applications. J Biomed Mater Res. 2009;09:263–71.

Geoghegan M, Krausch G. Wetting at polymer surfaces and interfaces. Prog Polym Sci. 2003;28:261–302.

Lisa T, Tim GM, Raju A, Francois M, Ranjith J, Ian G, Pathiraja AG. Thermoplastic biodegradable polyurethanes: the effect of chain extender structure on properties and in-vitro degradation. Biomaterials. 2007;28:5407–17.

Zhang C, Zhang N, Wen X. Synthesis and characterization of biocompatible, degradable, light-curable, polyurethane-based elastic hydrogels. J Biomed Mater Res. 2007;82A:637–50.

Castner DG, Ratner BD. Biomedical surface science: foundations to frontiers. Surf Sci. 2002;500:28–60.

Pai AS, Rubinstein I, Onyuksel H. PEGylated phospholipid nanomicelles interact with b-amyloid(1–42) and mitigate its b-sheet formation, aggregation and neurotoxicity in vitro. Peptides. 2006;27:2858–66.

Gogolewski S, Pennings AJ, Lommen E, Wildevuur CHRH, Nieuwenhuis P. Growth of a neo-artery induced by a biodegradable polymeric vascular prosthesis. Makromol Chem, Rapid Commun. 1983;4:213–9.

Gogolewski S, Galletti G. Degradable, microporous vascular prosthesis from segmented polyurethane. Colloid Polym Sci. 1986;264:854–8.

Gogolewski S, Walpoth B, Rheiner P. Polyurethane microporous membranes as pericardial substitutes. Colloid Polym Sci. 1987;265:971–7.

Gogolewski S, Pennings AJ. An artificial skin based on biodegradable mixtures of polylactides and polyurethanes for full-thickness skin wound covering. Makromol Chem Rapid Commun. 1983;4:675–80.

Lelah MD, Cooper SL. Polyurethanes in medicine. Boca Raton: CRC; 1986.

Katarzyna G, Sylwester G. Biodegradable polyurethanes for implants. II. In vitro degradation and calcification of materials from poly(ε-caprolactone)–poly(ethylene oxide) diols and various chain extenders. J Biomed Mater Res. 2002;60:592–606.

Aitken RR, Jeffs GMF. Thermoplastic polyurethane elastomers based on aliphatic diisocyanates: thermal transitions. Polymer. 1977;18:197–8.

Takahara A, Coury AJ, Hergenrother RW, Cooper SL. Effect of soft segment chemistry on the biostability of segmented polyurethanes. I. In vitro oxidation. J Biomed Mater Res. 1991;25:341–56.

Stokes K, Anderson JM, McVenes JM. Polyurethane elastomer biostability. J Biomater Appl. 1995;9:321–54.

Martins PALS, Filho ALS, Fonseca AMRM, Santos A, Santos L, Mascarenhas T, Jorge N, Ferreira AJM. Uniaxial mechanical behavior of the human female bladder. Int Urogynecol J. 2011;22:991–5.

Sharma B, Ubaghs L, Keul H, Hocker H, Loontjens T, van Benthem R. Synthesis and characterization of alternating poly(amide urethane)s from epsilon-caprolactone, diamines and diphenyl carbonate. Polymer. 2005;46:1775–83.

Martin DJ, Meijs GF, Renwick GM, McCarthy SJ, Gunatillake PA. The effect of average soft segment length on morphology and properties of a series of polyurethane elastomers. 1. Characterization of the series. J Appl Polym Sci. 1996;62:1377–86.

Kim Y, Kim S. Effect of chemical structure on the biodegradation of polyurethanes under composting conditions. Polym Degrad Stab. 1998;62:343–52.

Gupta D, Venugopal J, Prabhakaran MP, Dev VRG, Low S, Choon AT, Ramakrishna S. Aligned and random nanofibrous substrate for the in vitro culture of Schwann cells for neural tissue engineering. Acta Biomaterialia. 2009;5:2560–9.

Malafaya PB, Reis RL. Bilayered chitosan-based scaffolds for osteochondral tissue engineering: influence of hydroxyapatite on in vitro cytotoxicity and dynamic bioactivity studies in a specific double-chamber bioreactor. Acta Biomater. 2009;5:644–60.

Park HS, Seo JA, Lee HY, Kim HW, Wall IV, Gong MS, Knowles JC. Synthesis of elastic biodegradable polyesters of ethylene glycol and butylenes glycol from sebacic acid. Acta Biomater. 2012;8:2911–8.

Park HS, Gong MS, Knowles JC. Synthesis and biocompatibility properties of polyester containing various diacid based on isosorbide. J Biomater Appl. 2012;27:99–109.

Acknowledgments

This work was supported by WCU Program through the National Research Foundation of Korea (NRF) funded by the Ministry of Education, Science and Technology (No. R31-10069).

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Park, Hs., Gong, MS. & Knowles, J.C. Catalyst-free synthesis of high elongation degradable polyurethanes containing varying ratios of isosorbide and polycaprolactone: physical properties and biocompatibility. J Mater Sci: Mater Med 24, 281–294 (2013). https://doi.org/10.1007/s10856-012-4814-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10856-012-4814-0