Abstract

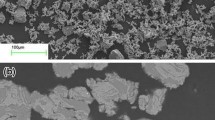

Shape memory alloys based on NiTi have found their main applications in manufacturing of new biomedical devices mainly in surgery tools, stents and orthopedics. Porous NiTi can exhibit an engineering elastic modulus comparable to that of cortical bone (12–17 GPa). This condition, combined with proper pore size, allows good osteointegration. Open cells porous NiTi was produced by self propagating high temperature synthesis (SHS), starting from Ni and Ti mixed powders. The main NiTi phase is formed during SHS together with other Ni–Ti compounds. The biocompatibility of such material was investigated by single culture experiment and ionic release on small specimen. In particular, NiTi and porous NiTi were evaluated together with elemental Ti and Ni reference metals and the two intermetallic TiNi3, Ti2Ni phases. This approach permitted to clearly identify the influence of secondary phases in porous NiTi materials and relation with Ni-ion release. The results indicated, apart the well-known high toxicity of Ni, also toxicity of TiNi3, whilst phases with higher Ti content showed high biocompatibility. A slightly reduced biocompatibility of porous NiTi was ascribed to combined effect of TiNi3 presence and topography that requires higher effort for the cells to adapt to the surface.

Similar content being viewed by others

References

Duerig T, Pelton A, Stockel. An overview of nitinol medical applications. Mater Sci Eng A Struct 1999; 273:149.

Elahinia M, Hashemi M, Tabesh M. Manufacturing and processing of NiTi implants: a review. Prog Mater Sci. 2012;57:911.

Greiner C, Oppenheimer SM, Dunand DC. High strength, low stiffness, porous NiTi with superelastic properties. Acta Biomater. 2005;1:705.

Alvarez K, Nakajima H. Metallic scaffold for bone regeneration. Materials. 2009;2:790.

Bansiddhi A, Sargeant TD, Stupp SI, Dunand DC. Porous NiTi for bone implants: a review. Acta Biomater. 2008;4:773.

Ou M, Watari F, Yokoama A, Matsuno H, Kawasaki T. Dissolution of nickel and tissue response observed by X-ray scanning analytical microscope. Biomaterials. 1999;20:747.

Es-Souni M, Es-Souni M, Fischer-Brandies H. Assessing the biocompatibility of NiTi shape memory alloys used for biomedical applications. Anal Bioanal Chem. 2005;381:557.

Bogdanski D, Koeller M, Mueller D, Muhr G, Bram M, Buchkremer HP, Stoever D, Choi D, Epple M. Easy assessment of the biocompatibility of NiTi alloys by in vitro cell culture experiments on a functionally graded Ni-NiTi-Ti material. Biomaterials. 2002;23:4549.

Vandenkerckhove R, Chandrasekaran M, Vermaut P, Portier R, Delaey L. Corrosion behaviour of a superelastic Ni–Ti alloy. Mater Sci Eng A Struct 2004; 378:532.

Shabalovskaya S, Shabalovskaya S, Van Humbeeck J. Critical overview of Nitinol surfaces and their modifications for medical applications. Acta Biomater. 2008;4:447.

Shabalovskaya S, Anderegg J, Van Humbeeck J. Recent observations of particulates in Nitinol. Mater Sci Eng A Struct 2008; 481:431.

Wever DJ, Veldhuizen AG, de Vries J, Busscher HJ, Uges DRA, van Horn JR. Cytotoxic, allergic and genotoxic activity of a nickel–titanium alloy. Biomaterials. 1997;18:1115.

Thierry B, Tabrizian M, Trépanier C, Savadogo O, Yahia LH. Effect of surface treatments and sterilization processes on the corrosion behavior of NiTi shape memory alloy. J Biomed Mater Res. 2000;51:685.

Rondelli G, Vicentini B, Cigada A. The corrosion behaviour of nickel titanium shape memory alloys. Corros Sci. 1990;30(8/9):805.

Shabalovskaya S, Anderegg J, Rondelli G, Vanderlinden W, De Feyter S. Comparative in vitro performances of bare Nitinol surfaces. Bio Med Mater Eng. 2008;18:1.

Zhao Y, Taya M, Kang Y, Kawasaki A. Compression behavior of porous NiTi shape memory alloy. Acta Mater. 2005;53:337.

Kaya M, Bugutekin A, Orhan N. Effect of solution treatment on thermal conductivity of porous NiTi shape memory alloy. Int J Thermophys. 2011;32:665.

Biswas A. Porous NiTi by thermal explosion mode of SHS: processing, mechanism and generation of single phase microstructure. Acta Mater. 2005;53:1415.

Zanotti C, Giuliani P, Bassani P, Zhang Z, Chrysanthou A. Comparison between the thermal properties of fully dense and porous NiTi SMAs. Intermetallics. 2010;18:14.

Papadopoulos NG, Dedoussis GV, Spanakos G, Gritzapis AD, Baxevanis CN, Papamichail M. An improved fluorescence assay for the determination of lymphocyte-mediated cytotoxicity using flow cytometry. J Immunol Methods. 1994;177:101.

Faulstich H, Zobeley S, Rinnerthaler G, Small JV. Fluorescent phallotoxins as probes for filamentous actin. J Muscle Res Cell Motil. 1988;5:370.

Plotkin L, Weinstein RS, Parfitt AM, Roberson PK, Manolagas SC, Bellido T. Prevention of osteocyte and osteoblast apoptosis by bisphosphonates and calcitonin. J Clin Invest. 1999;104:1363.

Liu Y, Peterson DA, Kimura H, Schubert D. Mechanism of cellular 3-(4,5-dimethylthiazol-2-yl)-2,5-diphenyltetrazolium bromide (MTT) reduction. J Neurochem. 1997;69:581.

Mazinanian N, Hedberg Y, Wallinder IO. Nickel release and surface characteristics of fine powders of nickel metal and nickel oxide in media of relevance for inhalation and dermal contact. Regul Toxicol Pharm 2013;65:135.

Anselme K. Osteoblast adhesion on biomaterials. Biomaterials. 2002;21:667.

Acknowledgments

The authors acknowledge G. Carcano, P. Giuliani and E. Bassani for technical support.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Bassani, P., Panseri, S., Ruffini, A. et al. Porous NiTi shape memory alloys produced by SHS: microstructure and biocompatibility in comparison with Ti2Ni and TiNi3 . J Mater Sci: Mater Med 25, 2277–2285 (2014). https://doi.org/10.1007/s10856-014-5253-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10856-014-5253-x