Abstract

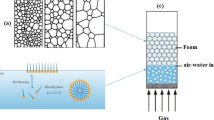

In this study we investigated the role of the water content of extrudates had in foaming capacity and searched for the water content giving the greatest expansion of starch extrudates. Porous structures based on potato amylopectin starch were prepared by extrusion followed by a microwave foaming process. Starch was first extruded with water, in order to incorporate water in the granular structure and achieve gelatinization. Extrudates were conditioned at humidities ranging from 11% to 97%. The water content in the starch extrudates was studied by a water vapor sorption isotherm study. Extrudates were analyzed with light microscopy and wide angle X-ray scattering studies to determine degree of crystallinity. In the second step, extrudates were foamed in a microwave oven. As the water started to boil, it acted as a blowing agent, leaving a porous closed-cell starch structure. The densities and the expansion ratios of the foamed samples are determined. Porosity was studied with environmental scanning electron microscopy. Mechanical properties as a function of the surrounding humidity were analyzed with dynamic mechanical analysis. We found that the maximal degree of expansion was in extrudates conditioned at 33% and 54% RH and having water content of 11.2% and 13.4%, respectively. This level of water is sufficient to expand the extrudate to a maximum level but not high enough to plasticize the starch and cause cell collapse after treatment.

Similar content being viewed by others

References

Swinkels JJM (1985) Starch/Stärke 37:1

Zobel HF (1988) Starch-Stärke 40:44

Buleon A, Colonna P (1998) Int J Biol Macromol 23:85

Lourdin D, Della Valle G, Colonna P (1995) Carbohydr Polym 27:261

Shogren RL, Fanta GF, Doane WM (1993) Starch-Stärke 45:276

Griffin GJL (1977) U.S. patent No. 4.021.388

French D (1984) Organization of starch granules. In: Whistler RL, Bemiller JN, Paschall EF (eds) Starch chemistry amd technology 2nd edition. Academic Press, New York, USA, 184–247

Blanshard JMV(1987) Starch granule structure and function: a physiochemical approach. In: Galliard T (ed) Starch: properties and potential.8 edn. New York, Wiley, 16–54

Shogren RL et al (1998) Polymer 39(25):6649

Glenn GM, Irving DW (1995) Cereal Chem 72:155

Sjöqvist M, Gatenholm P (2005) J Polym Environ 13:29

Stading M, Rindlav-Westling Å, Gatenholm P (2001) Carbohydr Polym 45:209

Trommsdorff U, Tomka I (1995) Macromolecules 28:6128

Kokini JL, Cocero AM, Madeka H, Degraaf E (1994) Trends Food Sci Technol 5:281

Trommsdorff U, Tomka I (1995) Macromolecules 28:6128

Ernoult V, Moraru CI, Kokini JL (2002) Cereal Chem 79:265

Chinnaswammy R, Hanna MA (1988) Cereal Chem 65:138

Willett JL, Shogren RL (2002) Polymer 43:5935

Buffler CR (1993) Microwave cooking and processing: engineering fundamentals for the food scientist. New York, Van Nostrand Reinhold

Moraru CI, Kokini JL (2003) Compr Rev Food Sci Safety 2:120

Singh J, Singh N (1999) J Food Eng 42:161

Boischot C, Moraru CI, Kokini JL (2003) Cereal Chem 80:56

Kokini JL, Lai LS, Chedid LL (2002) Food Technol 46:124

Hofvander P, Persson PT, Tallberg A, Wikström O (1992) Swedish patent SE 9004096 5

ASTM (2001) E104-85 Standard practice for maintaining constant relative humidity by means of aqueous solutions. Annual Book of ASTM Standards

Segnini S, Pedreschi F, Dejmek P (2004) Int J Food Properties 7:37

Sala RM, Tomka I (1992) Sorption Angew Makromol Chem 199:45

Slade L, Levine H (1991) Crit Rev Food Sci Nutr 30:115

Couchmann PR, Karasz FE (1978) Macromolecules 11:117

Brinke G, Karasz FE, Elllis TS (1983) Macromolecules 16:244

Acknowledgments

This work was funded by SCA Hygiene Products and KK foundation, through the Marchal program. Lyckeby stärkelsen is gratefully acknowledged for material supply. We appreciate our discussions with Dr Shabira Abbas at SCA and Dr Karin Svegmark. Thanks to Camilla Bemm at SCA for ESEM images and to Anne-Mari Olsson and Dr Lennart Salmén at STFI for help with DMA measurements.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sjöqvist, M., Gatenholm, P. Effect of Water Content in Potato Amylopectin Starch on Microwave Foaming Process. J Polym Environ 15, 43–50 (2007). https://doi.org/10.1007/s10924-006-0039-y

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10924-006-0039-y