Abstract

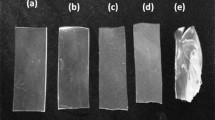

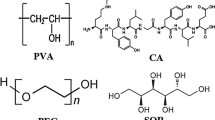

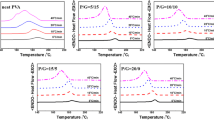

In this work, high-alcoholysis polyvinyl alcohol (PVA) films were fabricated by melt processing and the plasticizing effect of compound polyol plasticizers on PVA were investigated with X-ray diffraction (XRD), differential scanning calorimetry (DSC), rheological measurements, mechanical tests etc. Hydrogen bonding interactions occurred between PVA and plasticizer. With the increase of plasticizer, the flowability of PVA was improved and reached the maximum value at the plasticizer of 20%. Glass transition temperature (T g) and melting point (T m) decreased with the increase of plasticizer content. For the heterogeneous nucleation effect of plasticizer, new polymorph of PVA formed. The viscosity was sensitive to the shear rates. The incorporation of plasticizers into PVA resulted in the increase of elongation at break and impact strength, as well as the decrease of tensile strength.

Similar content being viewed by others

References

Finch CA (1992) Polyvinyl alcohol–development, Chaps. 1–3 and 12–18

Nakano N, Yamane S, Toyosima K (1989) Poval (polyvinyl-alcohol), Chap. 3. Japan Polymer Society, Kyoto, Japan, p 19

Lee WJ, Youn YN, Yun YH, Yoon SD (2007) J Polym Environ 15:35–42

Julinová M, Dvořáčková M, Kupec J, Hubáčková J, Kopčilová M, Hoffmann J, Alexy P, Nahálková A, Vašková I (2008) J Polym Environ 16:241–249

DeMerlis CC, Schoneker DR (2003) Food Chem Toxicol 41:319

Jayasekara R, Harding I, Bowater I, Christie GBY, Lonergan GT (2003) J Polym Environ 11:49–56

Chiellini E, Corti A, Solaro R (1999) Polym Degrad Stab 64:305–312

Jecu L, Gheorghe A, Rosu A, Raut I, Grosu E, Ghiurea M (2010) J Polym Environ 18:284–290

Kuang T, Du Z (1991) China patent ZL 86104040

Fujio M, Kenichi Y, Hiroshi K (1962) Japan patent 37009768

Jang J, Lee DK (2003) Polymer 44:8139–8146

Salzburg H, Reinking K, Kleiner F (1985) U.S.P. 4, 529, 666

Chen N, Li L, Wang Q (2007) Plast Rubber Compos 36:283–290

Xiang AM, Liu WC, Zhao QH, Kang ZY (2003) China Plastics 02:17–20

Nishino T, Kani S, Gotoh K, Nakamae K (2002) Polymer 43:2869

Ohhashi S, Yasumura K, Hayashi A, Fukushima M (1975) Japan patent 50035426

Haralabakopoulos AA, Tsiourvas D, Paleos CM (1996) J Appl Polym Sci 62:1597

Hiroshi N, Nobuo D, Takeaki M (1998) Polymer 36:3045

Piao D, Toshio K (1982) Sen’i Gakkaishi 38:43

Cheng LH, Karim AA, Seow CC (2006) J Food Sci E: Food Eng Phys Prop 71:62–67

Mohsin M, Hossin A, Haik Y (2011) Mater Sci Eng A 528:925–930

Paranhos CM, Soares BG, Oliveira RN, Pessan LA, Freitas DS, Windmoller D, Machado JC (2007) J Appl Polym Sci 105:899–902

Minus ML, Chae HG, Kumar S (2006) Polymer 47:3705–3710

Acknowledgments

This work was supported by the Scientific and Technological Development Project of Beijing Municipal Commission of Education (KZ201010011011).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wu, W., Tian, H. & Xiang, A. Influence of Polyol Plasticizers on the Properties of Polyvinyl Alcohol Films Fabricated by Melt Processing. J Polym Environ 20, 63–69 (2012). https://doi.org/10.1007/s10924-011-0364-7

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10924-011-0364-7