Abstract

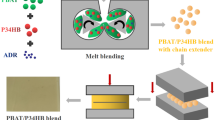

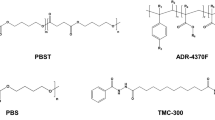

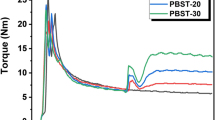

Two biodegradable polyesters, poly(butylene adipate-co-terephthalate) (PBAT) and poly(butylene succinate) (PBS) were melt-compounded in a twin screw extruder to fabricate a novel PBS/PBAT blend. The compatibility of the blend was attributed to the transesterification reaction that was confirmed by Fourier transform infrared spectroscopy. The Gibbs free energy equation was applied to explain the miscibility of the resulting blend. Dynamic mechanical analysis of the blends exhibits an intermediate tanδ peak compared to the individual components which suggests that the blend achieved compatibility. One of the key findings is that the tensile strength of the optimized blend is higher than each of the blended partner. Rheological properties revealed a strong shear-thinning tendency of the blend by the addition of PBAT into PBS. The phase morphology of the blends was observed through scanning electron microscopy, which revealed that phase separation occurred in the blends. The spherulite growth in the blends was highly influenced by the crystallization temperature and composition. In addition, the presence of a dispersed amorphous phase was found to be a hindrance to the spherulite growth, which was confirmed by polarizing optical microscopy. Furthermore, the increased crystallization ability of PBAT in the blend systems gives the blend a balanced thermal resistance property.

Similar content being viewed by others

References

Wu D, Yuan L, Laredo E, Zhang M, Zhou W (2012) Ind Eng Chem Res 51:2290–2298

Tokiwa Y, Calabia BP (2007) J Polym Environ 15:259–267

Zhang K, Mohanty AK, Misra M (2012) ACS Appl Mater Interfaces 4:3091–3101

Ouyang W, Huang Y, Luo H, Wang D (2012) J Polym Environ 20:1–9

Yu T, Luo F, Zhao Y, Wang D, Wang F (2011) J Appl Polym Sci 120:692–700

John J, Mani R, Bhattacharya M (2002) J Polym Sci A Polym Chem 40:2003–2014

Nanda MR, Misra M, Mohanty AK (2011) Macromol Mater Eng 296:719–728

Huang P, Zhong Z, Zheng S, Zhu W, Guo Q (1999) J Appl Polym Sci 73:639–647

Varughese KT, Nando GB, De PP, De SK (1988) J Mater Sci 23:3894–3902

Nesarikar AR, Carr SH, Khait K, Mirabella FM (1997) J Appl Polym Sci 63:1179–1187

Singh D, Malhotra VP, Vats JL (1999) J Appl Polym Sci 71:1959–1968

Tang W, Murthy NS, Mares F, McDonnell ME, Curran SA (1999) J Appl Polym Sci 74:1858–1867

Kotliar AM (1981) J Polym Sci Macromol Rev 16:367–395

Jayakannan M, Anilkumar P (2004) J Polym Sci A Polym Chem 42:3996–4008

Chen HL (1995) Macromolecules 28:2845–2851

Aravind I, Ahn KH, Ranganathaiah C, Thomas S (2009) Ind Eng Chem Res 48:9942–9951

Focarete ML, Scandola M, Dobrzynski P, Kowalczuk M (2002) Macromolecules 35:8472–8477

Aravind I, Eichhorn KJ, Komber H, Jehnichen D, Zafeiropoulos NE, Ahn KH, Grohens Y, Stamm M, Thomas S (2009) J Phys Chem B 113:1569–1578

Liu B, Bhaladhare S, Zhan P, Jiang L, Zhang J, Liu L, Hotchkiss AT (2011) Ind Eng Chem Res 50:13859–13865

Fujimaki T (1998) Polym Degrad Stab 59:209–214

Soccio M, Lotti N, Gigli M, Finelli L, Gazzano M, Munari A (2012) Polym Int 61:1163–1169

Huang CL, Jiao L, Zhang JJ, Zeng JB, Yang KK, Wang YZ (2012) Polym Chem 3:800–808

Kim SW, Lim JC, Kim DJ, Seo KH (2004) J Appl Polym Sci 92:3266–3274

Myriant Technologies websites. http://www.myriant.com/succinicpage.htm. Accessed on Febraury 2013

Yoo ES, Im SS (1999) J Polym Sci B Polym Phys 37:1357–1366

Wang J, Zheng L, Li C, Zhu W, Zhang D, Xiao Y, Guan G (2012) Polym Test 31:39–45

Qiu Z, Ikehara T, Nishi T (2003) Polymer 44:2503–2508

Kim YJ, Park OO (1999) J Polym Environ 7:53–66

Gu SY, Zhang K, Ren J, Zhan H (2008) Carbohydr Polym 74:79–85

Gan Z, Abe H, Kurokawa H, Doi Y (2001) Biomacromolecules 2:605–6013

Sykacek E, Hrabalova M, Frech H, Mundigler N (2009) Compos Part A Appl Sci Manuf 40:1272–1282

Javadi A, Kramschuster AJ, Pilla S, Lee J, Gong S, Turng LS (2010) Polym Eng Sci 50:1440–1448

Jiang L, Liu B, Zhang J (2009) Ind Eng Chem Res 48:7594–7602

Jang MO, Kim SB, Nam B-U (2012) Polym Bull 68:287–298

Javadi A, Srithep Y, Lee J, Pilla S, Clemons C, Gong S, Turng LS (2010) Compos Part A Appl Sci Manuf 41:982–990

Qiu Z, Ikehara T, Nishi T (2003) Polymer 44:3095–3099

Li Y, Shimizu H (2009) ACS Appl Mater Interfaces 1:1650–1655

Huang X, Li C, Zheng L, Zhang D, Guan G, Xiao Y (2009) Polym Int 58:893–899

Kwei TK (1984) J Polym Sci B 22:307–313

Wang LH, Huang Z, Hong T, Porter RS (1990) J Macromol Sci Phys B 29:155–169

Takiyama E, Fujimaki T, Seki S, Hokari T, Hatano Y (1994) US patent no. 5310782

Takiyama E, Hatano Y, Fujimaki T, Seki S, Hokari T, Hosogane T, Harigai N (1995) US patent no. 5436056

Mittal V (2012) Functional polymer blends: synthesis, properties, and performance. CRC Press, New York, p 235

Joseph K, Thomas S, Pavithran C (1996) Polymer 37:5139–5149

Dobkowski Z (1986) Rheol Acta 25:195–198

Carrasco F, Pagès P, Gámez-Pérez J, Santana O-O, Maspoch ML (2010) Polym Degrad Stab 95:116–125

Corre YM, Bruzaud S, Audic JL, Grohens Y (2012) Polym Test 31:226–235

Siciliano A, Seves A, Maro TD, Cimmino S, Martuscelli E, Silvestre C (1995) Macromolecules 28:8065–8072

Liu AS, Liau WB, Chiu WY (1998) Macromolecules 31:6593–6599

Richards E, Rizvi R, Chow A, Naguib H (2008) J Polym Environ 16:258–266

Parulekar Y, Mohanty AK (2007) Macromol Mater Eng 292:1218–1228

Mark JE (2006) Physical properties of polymers handbook, 2nd edn. Spring Science, New york 293

Jain S, Redy MM, Mohanty AK, Misra M, Ghosh AK (2010) Macromol Mater Eng 295:750–762

Menard KP (1999) Dynamic mechanical analysis: a practical introduction, 2nd edn. CRC Press, New York, p 85

Mohanty S, Nayak SK (2012) J Polym Environ 20:195–207

Aravind I, Boumod A, Grohens Y, Thomas S (2010) Ind Eng Chem Res 49:3873–3882

Thomas S, Gupta BR, De SK (1987) J Vinyl Technol 9:71–85

ASTM Standard D648 (2007) Standard test method for deflection temperature of plastics under flexural load in edgewise position. ASTM International, West Conshohocken, PA. www.astm.org.

Kawamoto N, Saki A, Horikoshi T, Urushihara T, Tobita E (2007) J Appl Polym Sci 103:244–250

Lu SF, Chen M, Chen CH (2012) J Appl Polym Sci 123:3610–3619

Chrissafis K, Paraskevopoulos KM, Bikiaris DN (2005) Thermochim Acta 435:142–150

Di Y, Iannace S, Maio ED, Nicolais L (2005) Macromol Mater Eng 290:1083–1090

Bhatia A, Gupta RK, Bhattacharya SN, Choi HJ (2007) Korea Aust Rheol J 19:125–131

Li K, Peng J, Turng LS, Huang HX (2011) Adv Polym Technol 30:150–157

Wang L, Jing X, Cheng H, Hu X, Yang L, Huang Y (2012) Ind Eng Chem Res 51:10088–10099

Wang T, Li H, Wang F, Schultz JM, Yan S (2011) Polym Chem 2:1688

Acknowledgments

The authors acknowledge the Ontario Ministry of Agriculture and Food (OMAF) and Ministry of Rural Affairs (MRA)—University of Guelph Bioeconomy-industrial uses research, for their sponsorships. They also gratefully acknowledge the Ontario Research Fund, Research Excellence, round-4 (ORF RE04) from Ontario Ministry of Economic Development and Innovation (MEDI), Natural Sciences and Engineering Research Council (NSERC), Networks of Centers of Excellence (NCE) and AUTO21 project for their financial support to carry out this research work.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Muthuraj, R., Misra, M. & Mohanty, A.K. Biodegradable Poly(butylene succinate) and Poly(butylene adipate-co-terephthalate) Blends: Reactive Extrusion and Performance Evaluation. J Polym Environ 22, 336–349 (2014). https://doi.org/10.1007/s10924-013-0636-5

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10924-013-0636-5