Abstract

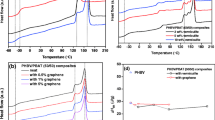

Manufacturing of plastics by biodegradable polymers can reduce the environmental impact and limit the recourse to non-renewable resources. Physical, chemical and mechanical properties of biodegradable polymers cannot often be comparable with petroleum-based plastics. However, the modification of bioplastics by physical and chemical routes can improve their performance. In this work, Poly(HydroxyButyrate) PHB is reprocessed by the dispersion of graphene nano-platelets as well as by the dispersion of Amino-Functionalized Nano-Silica (A-fnSiO2). Modification of the PHBs after compounding and pelletizing was evaluated by Fourier Transform Infrared. Thermal analysis was performed by Differential Scanning Calorimetry after extrusion and compression moulding. Hardness and scratch performance of the polymers were measured on compression molded substrates by pencil and progressive and constant load scratch tests. Chemical resistance was evaluated on compression molded substrates by dipping in aggressive acidic, basic and saline aqueous solutions. In conclusion, the PHBs modified by the graphene nanoplatelets were found to be very promising, featuring good chemical inertness, hardness and mechanical strength.

Similar content being viewed by others

References

Chudnovsky A, Zhou Z, Zhang H, Sehanobish K (2012) Lifetime assessment of engineering thermoplastics. Int J Eng Sci 59:108–139

Wang L, Wang Y-N, Huang Z-G, Weng Y-X (2015) Heat resistance, crystallization behavior, and mechanical properties of polylactide/nucleating agent composites. Mater Des 66:7–15

Mohanty AK, Misra M, Hinrichsen G (2000) Biofibers, biodegradable polymers and biocomposites—an overview. Macromol Mater Eng 276(277):1–24

Mathew AP, Oksman K, Sain M (2005) Mechanical properties of biodegradable cellulose (MCC). J Appl Polym Sci 97:2014–2025

Oksman K, Skrifvars M, Selin JF (2003) Natural fibres as reinforcement in polylactic acid (PLA) composites. Compos Sci Technol 63:1317–1324

Huda MS, Drzal LT, Mohanty AK, Misra M (2006) Chopped glass and recycled newspapers as reinforcement fibers in injection molded poly(lactic acid) (PLA) composites: a comparative study. Compos Sci Technol 66:1813–1824

Shibata M, Ozawa K, Teramoto N, Yosomiya R, Takeishi H (2003) Biocomposites made from short abaca fiber and biodegradable polyesters. Macromol Mater Eng 288:35–43

Bravo A, Toubal L, Koffi D, Erchiqui F (2015) Development of novel green and biocomposite materials: tensile and flexural properties and damage analysis using acoustic emission. Mater Des 66:16–28

Abdellaoui H, Bensalah H, Echaabi J, Bouhfid R, Qaiss A (2015) Fabrication, characterization and modelling of laminated composites based on woven jute fibres reinforced epoxy resin. Mater Des 68:104–113

Mohanty AK, Khan MA, Sahoo S, Hinrichsen G (2000) Effect of chemical modification on the performance of biodegradable jute–yarn/biopol composites. J Mater Sci 35:2589–2595

Bodros E, Pillin I, Montrelay N, Baley C (2007) Could biopolymers reinforced by randomly scattered flax fibre be used in structural applications? Compos Sci Technol 67(3–4):462–470

Lee SG, Choi SS, Park WH, Cho D (2003) Characterization of surface modified flax fibers and their biobased composites with PHB. Macromol Symp 197:89–99

Wong S, Shanks R, Hodzik A (2002) Properties of poly(3-hydroxybutyric acid) composites with flax fibres modified by plasticizer absorption. Macromol Mater Eng 287:647–655

Singh S, Mohanty AK, Sugie T, Takai Y, Hamada H (2008) Renewable resource based biobased composites from natural fiber and polyhydroxybutyrate-co-valerate (PHBV) bioplastic. Compos A 39:875–886

Melo JDD, Carvalho LFM, Medeiros AM, Souto CRO, Paskocimas CA (2012) A biodegradable composite material based on polyhydroxybutyrate (PHB) and carnauba fibers. Compos B 43:2827–2835

Pankova YN, Shchegolikhin AN, Iordanskii AL, Zhulkina AL, Ol’khov AA, Zaikov GE (2010) The characterization of novel biodegradable blends based on polyhydroxybutyrate: the role of water transport. J Mol Liq 156:65–69

Medvecky L, Sopcak T (2012) Preparation and properties of octacalcium phosphate-polyhydroxybutyrate thin film composites. Mater Lett 68:157–160

Noohom W, Jack KS, Martin D, Trau M (2009) Understanding the roles of nanoparticle dispersion and polymer crystallinity in controlling the mechanical properties of HA/PHBV nanocomposites. Biomed Mater 4:015003

Ojijo V, Ray SS (2013) Processing strategies in bionanocomposites. Prog Polym Sci 38:1543–1589

Ahmadi-Moghadam B, Sharafimasooleh M, Shadlou S, Taheri F (2015) Effect of functionalization of graphene nanoplatelets on the mechanical response of graphene/epoxy composites. Mater Des 66:142–149

Li Y, Pan D, Chen S, Wang Q, Pan G, Wang T (2013) In situ polymerization and mechanical, thermal properties of polyurethane/graphene oxide/epoxy nanocomposites. Mater Des 47:850–856

El Achaby M, Qaiss A (2013) Processing and properties of polyethylene reinforced by graphene nanosheets and carbon nanotubes. Mater Des 44:81–89

Gisario A, Barletta M, Conti C, Guarino S (2011) Springback control in sheet metal bending by laser-assisted bending: experimental analysis, empirical and neural network modelling. Opt Laser Eng 49:1372–1383

Xu Z, Liu Q, Finch JA (1997) Silanation and stability of 3-aminopropryl triethoxy silane on nanosized superparamagnetic particles: I. Direct silanation. Appl Surf Sci 120:269–278

Shukla SR, Harad AM (2006) Aminolysis of polyethylene terephthalate waste. Polym Degrad Stab 91:1850–1854

Hoang CN, Dang YH (2013) Aminolysis of poly(ethylene terephthalate) waste with ethylenediamine and characterization of α, ω-diamine products. Polym Degrad Stab 98:697–708

Song W, Zheng Z, Tang W, Wang X (2007) A facile approach to covalently functionalized carbon nanotubes with biocompatible polymer. Polymer 48:3658–3663

Yoon JT, Jeong YG, Lee SC, Min BG (2009) Influences of poly(lactic acid)-grafted carbon nanotube on thermal, mechanical, and electrical properties of poly(lactic acid). Polym Adv Technol 20:631–638

Amirian M, Chakoli AN, Sui JH, Cai W (2012) Enhanced mechanical and photoluminescence effect of poly(L-lactide) reinforced with functionalized multiwalled carbon nanotubes. Polym Bull 68:1747–1763

Olalde B, Aizpurua JM, Garcia A, Bustero I, Obieta I, Jurado MJ (2008) Singlewalled carbon nanotubes and multiwalled carbon nanotubes functionalized with poly(L-lactic acid): a comparative study. J Phys Chem C 112:10663–10667

Chen GX, Kim HS, Park BH, Yoon JS (2005) Controlled functionalization of multiwalled carbon nanotubes with various molecular-weight poly(L-lactic acid). J Phys Chem B 109:22237–22243

Wellen RMR, Rabello MS, Fechine GJM, Canedo EL (2013) The melting behaviour of poly(3-hydroxybutyrate) by DSC. Reproducibility study. Polym Test 32:215–220

Gunaratne LMWK, Shanks RA, Amarasinghe G (2004) Thermal history effects on crystallisation and melting of poly(3-hydroxybutyrate). Thermochim Acta 423:127–135

Chen C, Fei B, Peng S, Zhuang Y, Dong L, Feng Z (2002) Nonisothermal crystallization and melting behavior of poly(3-hydroxybutyrate) and maleated poly(3-hydroxybutyrate). Eur Polym J 38:1663–1670

Armentano I, Bitinis N, Fortunati E, Mattioli S, Rescignano N, Verdejo R, Lopez-Machado MA, Kenny JM (2013) Multifunctional nanostructured PLA materials for packaging and tissue engineering. Prog Polym Sci 38:1720–1747

Kirkland NT, Schiller T, Medhekar N, Birbilis N (2012) Exploring graphene as a corrosion protection barrier. Corros Sci 56:1–4

Liu J, Hua L, Li S, Yu M (2014) Graphene dip coatings: an effective anticorrosion barrier on aluminum. Appl Surf Sci. doi:10.1016/j.apsusc.2014.11.187

Conradi M, Kocijan A, Kek-Merl D, Zorko M, Verpoest I (2014) Mechanical and anticorrosion properties of nanosilica-filled epoxy-resin composite coatings. Appl Surf Sci 292:432–437

Bull SJ (1991) Failure modes in scratch adhesion testing. Surf Coat Technol 50:25–32

Chudnovsky A (2014) Slow crack growth, its modeling and crack-layer approach: a review. Int J Eng Sci 83:6–41

Jardret V, Morel P (2003) Viscoelastic effects on the scratch resistance of polymers: relationship between mechanical properties and scratch properties at various temperatures. Prog Org Coat 48:322–331

Barletta M, Pezzola S, Vesco S, Tagliaferri V, Trovalusci F (2014) Experimental evaluation of plowing and scratch hardness of aqueous two-component polyurethane (2K-PUR) coatings on glass and polycarbonate. Prog Org Coat 77:636–645

Barletta M, Rubino G, Tagliaferri V, Vesco S (2014) Design and manufacture of photoluminescent coatings on stainless steel substrates. Colloid Surface A 455:147–155

Venkatesh GS, Deb A, Karmarkar A, Chauhan SS (2012) Effect of nanoclay content and compatibilizer on viscoelastic properties of montmorillonite/polypropylene nanocomposites. Mater Des 37:285–291

Macchetta A, Pavan A, Savadori A (1989) Processing of viscoelastic data for engineering design with polymers. Mater Des 10:293–296

Dusunceli N, Colak OU (2008) The effects of manufacturing techniques on viscoelastic and viscoplastic behavior of high density polyethylene (HDPE). Mater Des 29:1117–1124

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Barletta, M., Trovalusci, F., Puopolo, M. et al. Engineering and Processing of Poly(HydroxyButyrate) (PHB) Modified by Nano-sized Graphene Nanoplatelets (GNP) and Amino-Functionalized Silica (A-fnSiO2). J Polym Environ 24, 1–11 (2016). https://doi.org/10.1007/s10924-016-0753-z

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10924-016-0753-z