Abstract

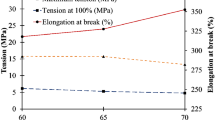

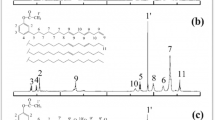

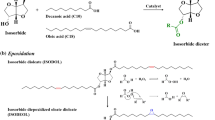

The use of alternative plasticizers with low toxicity and good compatibility with polyvinyl chloride (PVC) has become more attractive in the recent years in contrast with the phthalate derivatives. In this study, an additive derived from castor oil (methyl acetyl ricinoleate—MAR) was tested as a plasticizer for PVC. MAR was added to PVC in a range of 50–90 PHR and the increase of the plasticizer content had a great effect on maximum tension and tension at 100% of PVC samples. Moreover, the elongation at break also increased with the increase of plasticizer content. The good miscibility with PVC and therefore efficient plasticization action of MAR were proved by the DMA results, since narrow peaks of tan (δ) curves were observed. Moreover, the increase of MAR content reduced the Tg values of the samples [from 8.2 °C (50 PHR) to − 25.6 °C (90 PHR)]. PVC samples obtained using this bio-based plasticizer demonstrated good rheological properties [the increase of plasticizer content increased the MFI from 3.977 (50 PHR) up to 44.244 g.10 min−1 (90 PHR)] and proved to be thermally stable up to 200 °C. Finally, the MAR PVCs presented lower densities and lower hardness when compared with those produced from traditional plasticizes which are important aspects for the manufactories and consumers of PVC. In that sense, MAR proved to be a suitable plasticizer for PVC which may find a broad range of applications in the electric wires, carpets, hoses, shoes and construction industry, among many others.

Similar content being viewed by others

References

Burgess RH (1981) Manufacture and processing of PVC. CRC Press, Boca Raton

Wang J, Shu Z-J, Chen Z (2013) The protective effect of a fire-retardant coating on the insulation failure of PVC cable. Eng Fail Anal 34:1–9. https://doi.org/10.1016/j.engfailanal.2013.07.010

Chino S, Kato S, Seo J, Ataka Y (2009) Study on emission of decomposed chemicals of esters contained in PVC flooring and adhesive. Build Environ 44:1337–1342. https://doi.org/10.1016/j.buildenv.2008.07.003

Pearson R (1982) PVC as a food packaging material. Food Chem 8:85–96. https://doi.org/10.1016/0308-8146(82)90004-8

Bidoki SM, Wittlinger R (2010) Environmental and economical acceptance of polyvinyl chloride (PVC) coating agents. J Clean Prod 18:219–225. https://doi.org/10.1016/j.jclepro.2009.10.006

Arkema Inc. (2009) Arkema Inc introduces cost-effective tin stabilizers for rigid PVC pipe applications. Addit Polym 6:2–3. https://doi.org/10.1016/S0306-3747(09)70095-8

Patrick SG (2004) PVC compounds and processing. Rapra Technology Limited, Shawbury

Shah BL, Shertukde VV (2003) Effect of plasticizers on mechanical, electrical, permanence, and thermal properties of poly(vinyl chloride). J Appl Polym Sci 90:3278–3284. https://doi.org/10.1002/app.13049

Titow WV (1984) PVC technology, 4th edn. Rapra Technology Ltd, London

Wypych G (2013) Handbook of plasticizers. William Andrew, Toronto

Suarez Palacios OY, Narváez Rincón PC, Corriou J-P et al (2014) Multicriteria optimization of production conditions for a new phthalate-free PVC plasticizer. J Ind Eng Chem 20:1985–1992. https://doi.org/10.1016/j.jiec.2013.09.021

Jaakkola JJK, Knight TL (2008) The role of exposure to phthalates from polyvinyl chloride products in the development of asthma and allergies: a systematic review and meta-analysis. Environ Health Perspect 116:845–853. https://doi.org/10.1289/ehp.10846

Fenollar O, García D, Sánchez L et al (2009) Optimization of the curing conditions of PVC plastisols based on the use of an epoxidized fatty acid ester plasticizer. Eur Polym J 45:2674–2684. https://doi.org/10.1016/j.eurpolymj.2009.05.029

Yin B, Aminlashgari N, Yang X, Hakkarainen M (2014) Glucose esters as biobased PVC plasticizers. Eur Polym J 58:34–40. https://doi.org/10.1016/j.eurpolymj.2014.06.008

Mehta B, Kathalewar M, Sabnis A (2015) Cyclic carbonated soyabean oil as plasticizer for PVC for replacing di-octyl phthalate. J Polym Mater 32:17–29

Dutta K, Das S, Kundu PP (2014) Epoxidized esters of palm kernel oil as an effective plasticizer for PVC: a study of mechanical properties and effect of processing conditions. Int Polym Process 29:495–506. https://doi.org/10.3139/217.2922

Jia P, Xia H, Tang K et al (2018) Plasticizers Derived from biomass resources: a short review. Polymers 10:1303

Pandey D, Vatsa J (2010) Castor oil derivatives as potential plasticizers. Int R J Pharm Sci 01:51

Khiratkar AG, Balinge KR, Patle DS et al (2018) Transesterification of castor oil using benzimidazolium based Brønsted acid ionic liquid catalyst. Fuel 231:458–467

Chaudhary BI, Sczekalla B, Ghosh-Dastidar A et al (2011) Purified acetylated derivatives of castor oil and compostions including same. 15

Chaudhary BI, Sczekalla B, Meerbote M, Cheng Y (2010) Acetylated derivatives of castor oil and their blends with epoxidized fatty acid esters. 19

Savvashe PB, Kadam PG, Mhaske ST (2015) Ester-amide based on ricinoleic acid as a novel primary plasticizer for poly(vinyl chloride). J Appl Polym Sci 132:1–12

Chen J, Li K, Wang Y et al (2017) Synthesis and properties of a novel environmental epoxidized glycidyl ester of ricinoleic acetic ester plasticizer for poly(vinyl chloride). Polymers 9:640

Feng G, Jia P, Zhang L et al (2015) Synthesis of a novel phosphorus-containing plasticizer based on castor oil and its application for flame retardancy of polyvinyl chloride. Korean J Chem Eng 32:1201–1206

Jia P, Zhang M, Liu C et al (2015) Effect of chlorinated phosphate ester based on castor oil on thermal degradation of poly (vinyl chloride) blends and its flame retardant mechanism as secondary plasticizer. RSC Adv 5:41169–41178

Jia P-Y, Bo C-Y, Zhang L-Q et al (2015) Synthesis of castor oil based plasticizers containing flame retarded group and their application in poly (vinyl chloride) as secondary plasticizer. J Ind Eng Chem 28:217–224. https://doi.org/10.1016/j.jiec.2015.02.017

Jia P, Hu L, Zhang M, Zhou Y (2016) TG-FTIR and TG-MS analysis applied to study the flame retardancy of PVC–castor oil-based chlorinated phosphate ester blends. J Therm Anal Calorim 124:1331–1339

Jia P, Hu L, Feng G et al (2017) Design and synthesis of a castor oil based plasticizer containing THEIC and diethyl phosphate groups for the preparation of flame-retardant PVC materials. RSC Adv 7:897–903

ISO 527-1:1993 (1993) Determination of tensile properties

ISO 1133-1:2011 (2011) Determination of the melt mass-flow rate (MFR) and melt volume-flow rate (MVR) of thermoplastics

Pocius AV (2012) Adhesion and adhesives technology. https://doi.org/10.3139/9783446431775

ISO 868:2003 (2003) Determination of indentation hardness by means of a durometer (Shore hardness)

Jia P, Zhang M, Hu L et al (2015) Synthesis and application of phosphaphenanthrene groups-containing soybean-oil-based plasticizer. Ind Crops Prod 76:590–603

Unar IN, Soomro S, Aziz A S (2010) Effect of various additives on the physical properties of polyvinylchloride resin. Pakistan J Anal Environ Chem 11:44

Shenoy AV, Saini DR, Nadkarni VM (1983) Rheology of poly(vinyl chloride) formulations from melt flow index measurements. J Vinyl Addit Technol 5:192–197. https://doi.org/10.1002/vnl.730050409

Gil N, Saska M, Negulescu I (2006) Evaluation of the effects of biobased plasticizers on the thermal and mechanical properties of poly(vinyl chloride). J Appl Polym Sci 102:1366–1373. https://doi.org/10.1002/app.24132

Senake Perera M, Ishiaku U, Ishak M Z (2001) Characterisation of PVC/NBR and PVC/ENR50 binary blends and PVC/ENR50/NBR ternary blends by DMA and solid state NMR. Eur Polym J 37:167–178. https://doi.org/10.1016/S0014-3057(00)00085-9

Coltro L, Pitta JB, Madaleno E (2013) Performance evaluation of new plasticizers for stretch PVC films. Polym Test 32:272–278. https://doi.org/10.1016/j.polymertesting.2012.11.009

Mehta B, Kathalewar M, Sabnis A (2014) Benzyl ester of dehydrated castor oil fatty acid as plasticizer for poly(vinyl chloride). Polym Int 63:1456–1464

Una IN, Soomro SA, Aziz S (2010) Effect of various additives on the physical properties of polyvinylchloride resin. Pakistan J Anal Environ Chem 11:44–50

Feldman D (1984) Degradation and stabilisation of PVC. Springer, Dordrecht

Starnes WH (2002) Structural and mechanistic aspects of the thermal degradation of poly(vinyl chloride). Prog Polym Sci 27:2133–2170. https://doi.org/10.1016/S0079-6700(02)00063-1

McNeill IC, Memetea L, Cole WJ (1995) A study of the products of PVC thermal degradation. Polym Degrad Stab 49:181–191. https://doi.org/10.1016/0141-3910(95)00064-S

Altenhofen da Silva M, Adeodato Vieira MG, Gomes Maçumoto AC, Beppu MM (2011) Polyvinylchloride (PVC) and natural rubber films plasticized with a natural polymeric plasticizer obtained through polyesterification of rice fatty acid. Polym Test 30:478–484. https://doi.org/10.1016/j.polymertesting.2011.03.008

Janajreh I, Alshrah M, Zamzam S (2015) Mechanical recycling of PVC plastic waste streams from cable industry: a case study. Sustain Cities Soc 18:13–20. https://doi.org/10.1016/j.scs.2015.05.003

Jia P, Zhang M, Hu L et al (2015) Synthesis and application of environmental castor oil based polyol ester plasticizers for poly(vinyl chloride). ACS Sustain Chem Eng 3:2187–2193

Acknowledgements

This work is funded by ERDF Funds through Operational Competitiveness Programme—COMPETE in the frame of the Project GREENPEC—FCOMP-01-0202-FEDER-34132 and developed in the scope of the Project CICECO-Aveiro Institute of Materials (Ref. FCT UID/CTM/50011/2013), financed by national funds through the FCT/MEC and when applicable co-financed by FEDER under the PT2020 Partnership Agreement.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Gama, N.V., Santos, R., Godinho, B. et al. Methyl Acetyl Ricinoleate as Polyvinyl Chloride Plasticizer. J Polym Environ 27, 703–709 (2019). https://doi.org/10.1007/s10924-019-01383-5

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10924-019-01383-5