Abstract

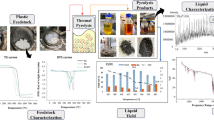

The inappropriate disposal of plastic waste causes serious environmental problems. Nowadays, alternative processes are being studied for the sustainable reutilization of plastics. One of these options is the cracking into shorter liquid hydrocarbon fractions, while maintaining its basic chemical structure. The energetic potential from the original plastics structure remains and the fractions can be used as fuels and chemical precursors. This research addresses the kinetic study of thermal cracking of polypropylene (PP) and high- and low-density polyethylene (HDPE and LDPE) in a batch reactor. The kinetics of the reaction can be described as a first-order rate with the lowest activation energy using PP, followed by HDPE and LDPE with values of 367.28 kJ/mol, 453.37 kJ/mol and 457.96 kJ/mol, respectively. The yield obtained for the liquid fraction is highest for LDPE, with a value of 72% at 390 °C, followed by HDPE and PP with 69% and 62% at 375 °C. The liquid fractions obtained from the process were characterized according to ASTM standards, obtaining that LDPE and HDPE fractions have similar properties to diesel, while PP is closer to gasoline. The fractions were also analyzed by means of gas chromatography identifying the main products of the reaction and establishing a possible reaction mechanism.

Similar content being viewed by others

References

Adnan SJ, Jan MR (2017) Recovery of valuable hydrocarbons from waste polystyrene using zinc supported catalysts. J Polym Environ 25:759–769. https://doi.org/10.1007/s10924-016-0858-4

Monteiro RCP, Ivar do Sul JA, Costa MF (2018) Plastic pollution in islands of the Atlantic Ocean. Environ Pollut 238:103–110. https://doi.org/10.1016/j.envpol.2018.01.096

Ritchie H, Roser M (2020) Plastic Pollution. OurWorldInData.org https://doi.org/https://doi.org/10.1142/9781786347435_0005

Andrady AL, Neal MA (2009) Applications and societal benefits of plastics. Philos Trans R Soc B Biol Sci 364:1977–1984. https://doi.org/10.1098/rstb.2008.0304

Plastics Europe (2019) Plastics - the Facts 2019. An Analysis of European Plastics Production, Demand and Waste Data. Bruselas, Belgica

Cheng L, Gu J, Wang Y et al (2020) Polyethylene high-pressure pyrolysis: better product distribution and process mechanism analysis. Chem Eng J 385:123866. https://doi.org/10.1016/j.cej.2019.123866

Martínez Urreaga J, González-Sánchez C, Martínez-Aguirre A et al (2015) Sustainable eco-composites obtained from agricultural and urban waste plastic blends and residual cellulose fibers. J Clean Prod 108:377–384. https://doi.org/10.1016/j.jclepro.2015.06.001

Thompson RC, Moore CJ, Saal FSV, Swan SH (2009) Plastics, the environment and human health: current consensus and future trends. Philos Trans R Soc B Biol Sci 364:2153–2166. https://doi.org/10.1098/rstb.2009.0053

de Camargo RV, Saron C (2020) Mechanical-chemical recycling of low-density polyethylene waste with polypropylene. J Polym Environ 28:794–802. https://doi.org/10.1007/s10924-019-01642-5

Patil L, Varma AK, Singh G, Mondal P (2018) Thermocatalytic degradation of high density polyethylene into liquid product. J Polym Environ 26:1920–1929. https://doi.org/10.1007/s10924-017-1088-0

Eriksson O, Finnveden G (2009) Plastic waste as a fuel - CO2-neutral or not? Energy Environ Sci 2:907–914. https://doi.org/10.1039/b908135f

Mrowiec B (2017) Plastic pollutants in water. Ios-Pib 28:51–55. https://doi.org/10.1515/OsZn-2017-0030

Lebreton LCM, Van Der Zwet J, Damsteeg JW et al (2017) River plastic emissions to the world’s oceans. Nat Commun 8:1–10. https://doi.org/10.1038/ncomms15611

Leal Filho W, Saari U, Fedoruk M et al (2019) An overview of the problems posed by plastic products and the role of extended producer responsibility in Europe. J Clean Prod 214:550–558. https://doi.org/10.1016/j.jclepro.2018.12.256

Huysman S, De Schaepmeester J, Ragaert K et al (2017) Performance indicators for a circular economy: a case study on post-industrial plastic waste. Resour Conserv Recycl 120:46–54. https://doi.org/10.1016/j.resconrec.2017.01.013

Hazrat MA, Rasul MG, Khan MMK (2015) A study on thermo-catalytic degradation for production of clean transport fuel and reducing plastic wastes. Procedia Eng 105:865–876. https://doi.org/10.1016/j.proeng.2015.05.108

Ajibola AA, Omoleye JA, Efeovbokhan VE (2018) Catalytic cracking of polyethylene plastic waste using synthesised zeolite Y from Nigerian kaolin deposit. Appl Petrochemical Res 8:211–217. https://doi.org/10.1007/s13203-018-0216-7

Chandrasekaran SR, Kunwar B, Moser BR et al (2015) Catalytic thermal cracking of postconsumer waste plastics to fuels. 1. Kinetics and optimization. Energy Fuels 29:6068–6077. https://doi.org/10.1021/acs.energyfuels.5b01083

Das S, Paney S (2007) Pyrolysis and Catalytic Cracking of Municipal Plastic Waste for Recovery of Gasoline Range Hydrocarbons Pyrolysis and Catalytic Cracking of Municipal Plastic Waste for Recovery of Gasoline Range Hydrocarbons. Thesis Natl Inst Technol Rourkela 10–55

Ragaert K, Delva L, Van Geem K (2017) Mechanical and chemical recycling of solid plastic waste. Waste Manag 69:24–58. https://doi.org/10.1016/j.wasman.2017.07.044

Anuar Sharuddin SD, Abnisa F, Wan Daud WMA, Aroua MK (2017) Energy recovery from pyrolysis of plastic waste: study on non-recycled plastics (NRP) data as the real measure of plastic waste. Energy Convers Manag 148:925–934. https://doi.org/10.1016/j.enconman.2017.06.046

Vas JP, Ramya AL, Dsilva E, Serrao FD (2017) Production of high grade liquid fuel for ci engine by thermo-catalytic cracking of waste plastic. Energy Power 7:81–87. https://doi.org/10.5923/j.ep.20170703.05

Miandad R, Barakat MA, Aburiazaiza AS et al (2017) Effect of plastic waste types on pyrolysis liquid oil. Int Biodeterior Biodegrad 119:239–252. https://doi.org/10.1016/j.ibiod.2016.09.017

Liu W, Wang C, Herold F et al (2019) Oxidative dehydrogenation on nanocarbon: effect of heteroatom doping. Appl Catal B Environ. https://doi.org/10.1016/j.apcatb.2019.117982

Bockhorn H, Hentschel J, Hornung A, Hornung U (1999) Environmental engineering: stepwise pyrolysis of plastic waste. Chem Eng Sci 54:3043–3051. https://doi.org/10.1016/S0009-2509(98)00385-6

Vargas DC, Alvarez MB, Hidrobo Portilla A et al (2016) Kinetic study of the thermal and catalytic cracking of waste motor oil to diesel-like fuels. Energy Fuels 30:9712–9720. https://doi.org/10.1021/acs.energyfuels.6b01868

ASTM:D1298–12b (2012) Standard Test Method for Density, Relative Density, or API Gravity of Crude Petroleum and Liquid Petroleum Products by Hydrometer Method. ASTM Int 99:1–8. https://doi.org/10.1520/D1298-12B.2

ASTM D445–06 (2008) Standard Test Method for Kinematic Viscosity of Transparent and Opaque Liquids (and Calculation of Dynamic Viscosity). Man Hydrocarb Anal 6th Ed 1–10

ASTM D92 (2005) Standard Test Method for Flash and Fire Points by Cleveland Open Cup Tester. Annu B ASTM Stand i:3–7. https://doi.org/https://doi.org/10.1520/D3638-12.2

Levenspiel O (2004) Chemical Reaction Engineering, 3rd ed. México

Yan G, Jing X, Wen H, Xiang S (2015) Thermal cracking of virgin and waste plastics of PP and LDPE in a semibatch reactor under atmospheric pressure. Energy Fuels 29:2289–2298. https://doi.org/10.1021/ef502919f

Panda K (2018) Thermo-catalytic degradation of different plastics to drop in liquid fuel using calcium bentonite catalyst. Int J Ind Chem 9:167–176. https://doi.org/10.1007/s40090-018-0147-2

Mills, Nigel; Jenkins, Mike; Kukureka S (2005) Plastics: Microstructure and Engineering Applications. In: Butterworth-Heinemann (ed) 4th ed. p 528

Ahmad I, Ismail Khan M, Khan H et al (2015) Pyrolysis study of polypropylene and polyethylene into premium oil products. Int J Green Energy 12:663–671. https://doi.org/10.1080/15435075.2014.880146

Ding F, Xiong L, Luo C et al (2012) Kinetic study of low-temperature conversion of plastic mixtures to value added products. J Anal Appl Pyrolysis 94:83–90. https://doi.org/10.1016/j.jaap.2011.11.013

Aguado J, Serrano DP, Escola JM (2008) Fuels from waste plastics by thermal and catalytic processes: a review. Ind Eng Chem Res 47:7982–7992. https://doi.org/10.1021/ie800393w

Rasul Jan M, Shah J, Gulab H (2013) Catalytic conversion of waste high-density polyethylene into useful hydrocarbons. Fuel 105:595–602. https://doi.org/10.1016/j.fuel.2012.09.016

Ballice L, Reimert R (2002) Classification of volatile products from the temperature-programmed pyrolysis of polypropylene (PP), atactic-polypropylene (APP) and thermogravimetrically derived kinetics of pyrolysis. Chem Eng Process 41:289–296. https://doi.org/10.1016/S0255-2701(01)00144-1

Kurort T, Sekiguchi Y, Ogawa T et al (2000) Thermal degradation of polystyrene. Nippon Kagaku Kaishi 1977:894–901. https://doi.org/10.1246/nikkashi.1977.894

Gao Z, Amasaki I, Kaneko T, Nakada M (2003) Calculation of activation energy from fraction of bonds broken for thermal degradation of polyethylene. Polym Degrad Stab 81:125–130. https://doi.org/10.1016/S0141-3910(03)00081-8

Levine SE, Broadbelt LJ (2009) Detailed mechanistic modeling of high-density polyethylene pyrolysis: low molecular weight product evolution. Polym Degrad Stab 94:810–822. https://doi.org/10.1016/j.polymdegradstab.2009.01.031

Al-Salem SM, Lettieri P (2010) Kinetic study of high density polyethylene (HDPE) pyrolysis. Chem Eng Res Des 88:1599–1606. https://doi.org/10.1016/j.cherd.2010.03.012

Acknowledgments

This research has been supported by the USFQ Poli Grant 2017. Grant Number HUBI 5508.

Author information

Authors and Affiliations

Contributions

Conceptualization: DAS; Methodology: YRL, JN. Formal analysis and investigation: YRL, ASTM. Writing—original draft preparation: YRL, JN, ASTM. Writing—review and editing: YRL, JN, DAS. Funding acquisition: DAS. Resources: YRL, JN, DAS. Supervision: DAS, JN.

Corresponding author

Ethics declarations

Conflict of interest

All authors confirm that they don’t have any conflict of interests regarding sources of funding, financial or non-financial interests.

Human Rights and Animal Participants

This research did not involve humans and/or animals, nor required consent of involved human participants.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

10924_2021_2150_MOESM1_ESM.docx

Supporting information corresponds to the experimental data and its application for determining the differential and integral methods as well as the Arrhenius analysis for HDPE and LDPE (DOCX 83 kb)

Rights and permissions

About this article

Cite this article

Rodríguez Lamar, Y., Noboa, J., Torres Miranda, A.S. et al. Conversion of PP, HDPE and LDPE Plastics into Liquid Fuels and Chemical Precursors by Thermal Cracking. J Polym Environ 29, 3842–3853 (2021). https://doi.org/10.1007/s10924-021-02150-1

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10924-021-02150-1