Abstract

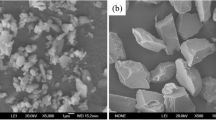

An improved gel-casting procedure was successfully exploited to produce porous ceramic bodies having controlled porosity features in terms of mean pore size, total pore volume as well as pore geometry. The gel-casting process in which a natural gelatine for food industry is used as gelling agent was firstly set-up to prepare dense alumina and zirconia components. Then, commercial PE spheres, sieved to select proper dimensional ranges, were added to the starting slurries as pore-forming agent. Both alumina and zirconia porous bodies were then produced, having a porosity ranging between 40 and 50 vol%. The fired components were characterised by spherical pores surrounded by highly dense ceramic walls and struts, having a homogeneous and fine microstructure. Their mean pore size was directly dependent on the sieved fraction of the starting PE spheres selected as pore-forming phase.

Similar content being viewed by others

References

O.O. Omatete, M.A. Janney, R.A. Strehlow, Am. Ceram. Soc. Bull. 70, 1641 (1991)

A.C. Young, O.O. Omatete, M.A. Janney, P.A. Menchhofer, J. Am. Ceram. Soc. 74, 612 (1991). doi:10.1111/j.1151-2916.1991.tb04068.x

I. Santacruz, M.I. Nieto, R. Moreno, Ceram. Int. 31, 439 (2005). doi:10.1016/j.ceramint.2004.06.007

J. Sun, L. Gao, Ceram. Int. 29, 971 (2003). doi:10.1016/S0272-8842(03)00050-6

E. Adolfsson, J. Am. Ceram. Soc. 89, 1897 (2006). doi:10.1111/j.1551-2916.2006.01040.x

B. Chen, Z. Zhang, J. Zhang, M. Dong, D. Jiang, Mater. Sci. Eng. A 435–436, 198 (2006). doi:10.1016/j.msea.2006.07.028

S. Padilla, M. Vallet-Regì, M.P. Ginebra, F.J. Gil, J. Eur. Ceram. Soc. 25, 375 (2005). doi:10.1016/j.jeurceramsoc.2004.02.017

W. Zhang, H. Wang, Z. Jin, Mater. Lett. 59, 250 (2005). doi:10.1016/j.matlet.2004.07.059

Q. Zhang, M. Gu, Mater. Sci. Eng. A 399, 3510 (2005). doi:10.1016/j.msea.2005.04.021

J.K. Park, J.S. Lee, S.I. Lee, J Porous Mater. 9, 203 (2002). doi:10.1023/A:1020939018359

M.A. Janney, O.O. Omatete, C.A. Walls, S.D. Nunn, R.J. Ogle, G. Westmoreland, J. Am. Ceram. Soc. 81, 581 (1998)

E. Gregorovà, W. Pabst, J. Stetina, J. Eur. Ceram. Soc. 26, 1185 (2006). doi:10.1016/j.jeurceramsoc.2005.01.046

I. Santacruz, C. Baudìn, M.I. Nieto, R. Moreno, J. Eur. Ceram. Soc. 23, 1785 (2003). doi:10.1016/S0955-2219(03)00011-6

Y. Chen, Z. Xie, J. Yang, Y. Huang, J. Eur. Ceram. Soc. 19, 271 (1999). doi:10.1016/S0955-2219(98)00201-5

L.J. Vandeperre, A.M. De Wilde, J. Luyten, J. Mater. Process. Technol. 135, 312 (2003). doi:10.1016/S0924-0136(02)00862-2

F.S. Ortega, F.A.O. Valenzuela, C.H. Scaracchio, V.C. Pandolfelli, J. Eur. Ceram. Soc. 23, 75 (2003). doi:10.1016/S0955-2219(02)00075-4

S. Dhara, P. Bhargava, J. Am. Ceram. Soc. 84, 3048 (2001)

C.H. Schilling, P. Tomasik, C. Li, M. Sikora, Mater. Sci. Eng. A 336, 219 (2002). doi:10.1016/S0921-5093(01)01959-1

O. Lyckfeldt, J. Brandt, S. Lesca, J. Eur. Ceram. Soc. 20, 2551 (2000). doi:10.1016/S0955-2219(00)00136-9

A.R. Studart, U.T. Gonzenbach, E. Tervoort, L.J. Gauckler, J. Am. Ceram. Soc. 89, 1771 (2006). doi:10.1111/j.1551-2916.2006.01044.x

S. Bhattacharjee, L. Besra, B.P. Singh, J. Eur. Ceram. Soc. 27, 47 (2007). doi:10.1016/j.jeurceramsoc.2006.01.023

R.L. Menchavez, M. Fuji, H. Takegami, M. Takahashi, Mater. Lett. 61, 754 (2007). doi:10.1016/j.matlet.2006.05.072

S. Padilla, J. Romàn, M. Vallet, Regi. J. Mater. Sci. Mater. Med. 13, 1193 (2002). doi:10.1023/A:1021162626006

H.R. Ramay, M. Zhang, Biomaterials 24, 3293 (2003). doi:10.1016/S0142-9612(03)00171-6

H.T. Wang, X.Q. Liu, G.Y. Meng, Mater. Res. Bull. 32, 1705 (1997). doi:10.1016/S0025-5408(97)00152-9

Y. Gu, X. Liu, G. Meng, D. Peng, Ceram. Int. 25, 705 (1999). doi:10.1016/S0272-8842(99)00005-X

C. Ha, Y. Jung, J. Kim, C. Jo, U. Paik, Mater. Sci. Eng. A 337, 212 (2002). doi:10.1016/S0921-5093(02)00034-5

G.Y. Onada, E.G. Liniger, Phys. Rev. Lett. 64, 2727 (1990). doi:10.1103/PhysRevLett.64.2727

Acknowledgments

The Authors wish to thank the European Community and the Italian Inter-University National Consortium on Material Science and Technology (INSTM) to have partially supported this research in the frame of the IP NanoKer and Prisma Projects, respectively.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Lombardi, M., Naglieri, V., Tulliani, JM. et al. Gelcasting of dense and porous ceramics by using a natural gelatine. J Porous Mater 16, 393–400 (2009). https://doi.org/10.1007/s10934-008-9212-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10934-008-9212-0