Abstract

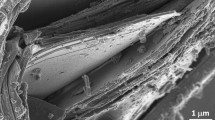

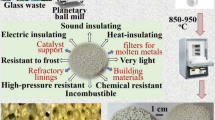

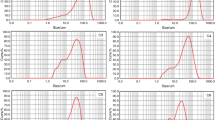

Waste soda-lime glass, alone or mixed with wastes from the manufacturing of glass fibers, was successfully converted into partially crystallized glass foams by a particularly simple and economic processing, consisting of a direct heating of glass powders at temperatures from 900 to 1050 °C. The foaming operated by the oxidation of SiC, inserted as powder additive, was found to depend on a complex combination of processing temperature, soaking time, tendency of the investigated glasses toward devitrification, and amount of MnO2, acting as oxidation promoter. Selected combinations led to foams with a good microstructural homogeneity and mechanical strength, suitable for application as aggregates in lightweight concrete.

Similar content being viewed by others

References

A. Mueller, S.N. Sokolova, V.I. Vereshagin, Construct. Build. Mater. 22, 703 (2008). doi:10.1016/j.conbuildmat.2007.06.009

G. Scarinci, G. Brusatin, E. Bernardo, in Cellular ceramics, structure, manufacturing, properties and applications, ed. by M. Scheffler, P. Colombo (Wiley-VCH, Weinheim, 2005), pp. 158–176

P. Colombo, G. Brusatin, E. Bernardo, G. Scarinci, Curr. Opin. Solid. State. Mater. Sci. 7, 225 (2003). doi:10.1016/j.cossms.2003.08.002

E. Bernardo, G. Scarinci, S. Hreglich, Glass Sci. Technol. 78, 7 (2005)

W.O. Lytle, U.S. Patent 2,215,223, 1940

B.K. Demidovich, Production and application of glass foam (Nauka i Tekhnika, Minsk, 1972)

E.H. Haux, U.S. Patent 2,191,658, 1940

W.D. Ford, U.S. Patent 2,691,248, 1954

J. Hurley, Glass research and development final report: a UK market survey for foam glass. (WRAP, The Waste and Resources Action Programme, 2003), http://www.wrap.org.uk/downloads/AUKMarketSurveyForFoamGlass.ed91e9c7.358.pdf, Accessed 8 Jan 2009

E. Bernardo, R. Cedro, M. Florean, S. Hreglich, Ceram. Int. 33, 963 (2007). doi:10.1016/j.ceramint.2006.02.010

http://www.sasil-life.com/pagine_UK/default_uk.html, Accessed 12 March 2009

http://www.enco.ch/glass.htm, Accessed 8 January 2009

A. Saburit Llaudis, M.J. Orts Tari, F.J. García Ten, E. Bernardo, P. Colombo, Ceram. Int. (2008). doi:10.1016/j.ceramint.2008.10.022

J.E. Post, Proc. Natl. Acad. Sci. USA 96, 3447 (1999). doi:10.1073/pnas.96.7.3447

K.L. Berg, S.E. Olsen, Metall. Mater. Trans. 31B, 477 (2000)

G. Brusatin, G. Scarinci, L. Zampieri, P. Colombo, in Proceedings of the XIXth International Congress on Glass—ICG XIX, vol. 2 (Society of Glass Technology, Edinburgh, 2001), pp. 17–18

D.U. Tulyaganov, H.R. Fernandes, S. Agathopoulos, J.M.F. Ferreira, J. Porous. Mater. 13, 133 (2006)

H. Hojaji, Mater. Res. Soc. Proc. 136, 185 (1989)

A.A. Ketov, in Proceedings of the International Symposium on Recycling and Reuse of Glass Cullet, ed. by R.K. Dhir et al. (Thomas Telford Books, Dundee, 2001), pp. 84–91

E. Bernardo, F. Albertini, Ceram. Int. 32, 603 (2006). doi:10.1016/j.ceramint.2005.04.019

Ducman V, Kovačević M (1997). Key Eng. Mater. 132–136:2264. doi:10.4028/www.scientific.net/KEM.132-136.2264

L.J. Gibson, M.F. Ashby, Cellular solids, structure and properties (Cambridge University Press, Cambridge, 1999), pp. 175–231

E. Bernardo, P. Colombo, in Ceramic science and technology, ed. by R. Riedel, I.-W. Chen, vol. 1 (Wiley-VCH, Weinheim, 2008), pp. 407–442

E. Bernardo, J. Eur. Ceram. Soc. 27, 2415 (2007). doi:10.1016/j.jeurceramsoc.2006.10.003

W. Höland, G.G. Beall, Glass–ceramic technology (The American Ceramic Society, Westerville, 2002), pp. 110–119

http://webmineral.com/data/Bustamite.shtml, Accessed 17 March 2009

S. Fotiadou, M.C. Limbachiya, A.N. Fried, J.J. Roberts, in Sustainable waste management and recycling of glass waste, ed. by M.C. Limbachiya, J. Roberts (Thomas Telford Ltd, London, 2004), pp. 305–312

M.J.M. Moons, K. Van Breugel, in Sustainable waste management and recycling of glass waste, ed. by M.C. Limbachiya, J. Roberts (Thomas Telford Ltd, London, 2004), pp. 197–204

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Bernardo, E., Scarinci, G., Bertuzzi, P. et al. Recycling of waste glasses into partially crystallized glass foams. J Porous Mater 17, 359–365 (2010). https://doi.org/10.1007/s10934-009-9286-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10934-009-9286-3