Abstract

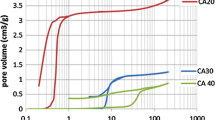

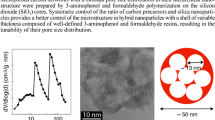

Porous carbons were synthesized from aqueous sodium carbonate catalysed solutions of the low cost precursors phenol and formaldehyde, applying ambient pressure drying without prior solvent exchange. Many of the samples are found to crack during drying, however, the resulting porous carbons show porosities up to 80%, specific surface areas up to 746 m2/g, and micropore volumes up to 0.29 cm3/g; the mesopore volume and external surface area of the derived carbons, however, is small indicating the dominance of macropores. An unusual gelation kinetic, i.e., the formation of precipitating flakes instead of the classical sol–gel-transition is observed; this is likely due to nuclei growth from a metastable state in the phase diagram and makes it challenging to reproduce samples with well defined properties. Nevertheless mechanically stable macroporous monoliths, that survive the ambient pressure drying without prior solvent exchange can be synthesized; the system presented, however, seems not to be suitable as base system for highly mesoporous carbon samples (aerogels, cryogels, xerogels) or large scale production of porous carbon materials.

Similar content being viewed by others

Notes

In most publications on gels derived from hydroxybenzols and aldehydes, the basic or acidic solutions added to control the reaction are denoted as “catalyst”; in fact using this denotation is strictly speaking not correct, because the pH-value changes as the polymerization reaction proceeds [34]. However, for convenience, we also denote the base or acid as “catalyst”.

Source: material safety data sheets from Merck KGaA.

Due to the fact, that the pH varies during the reaction, the P:C-ratio is the more suitable parameter to define the starting conditions. Indeed Na2CO3 is not a true “catalyst”.

References

R.W. Pekala, J. Mater. Sci. 24, 3221 (1989)

R.W. Pekala, F.M. Kong, J. Phys. 50, C433 (1989)

R.W. Pekala, C.T. Alviso, F.M. Kong, S.S. Hulsey, J. Non-Cryst. Solids 145, 90 (1992)

T. Yamamoto, T. Nishimura, T. Suzuki, H. Tamon, Drying Technol. 19, 1319 (2001)

A. Leonard, N. Job, S. Blacher, J.P. Pirard, M. Crine, W. Jomaa, Carbon 43, 1808 (2005)

N. Job, F. Sabatier, J.P. Pirard, M. Crine, A. Leonard, Carbon 44, 2534 (2006)

O. Czakkel, Microporous Mesoporous Mater. 86, 124 (2005)

N. Job, A. Thery, R. Pirard, J. Marien, L. Kocon, J.N. Rouzaud et al, Carbon 43, 2481 (2005)

W.C. Li, S.C. Guo, Carbon 38, 1520 (2000)

W.C. Li, A.H. Lu, S.C. Guo, J. Colloid Interface Sci. 254, 153 (2002)

W.C. Li, G. Reichenauer, J. Fricke, Carbon 40, 2955 (2002)

J. Gross, C.T. Alviso, J.K. Nielsen, R.W. Pekala, Mater. Res. Soc. Symp. Proc. 431, 123 (1996)

R.W. Pekala, J. Fricke, in Encyclopedia of Materials, vol. 7, ed. by J. Buschow, R.W. Cahn, M.C. Flemings, B. Ilschner, E. Kramer, S. Mahajan (Elsevier, Amsterdam, 2001), pp. 6502–6506

R. Brandt, Sauer katalysierte, unterkritisch getrocknete Resorcin-Formaldehyd-Aerogele und daraus abgeleitete Kohlenstoff-Aerogele, Ph.D. Thesis (University Würzburg, 2005)

G. Carlson, D. Lewis, K. McKinley, J. Richardson, T. Tillotson, J. Non-Cryst. Solids 186, 372 (1995)

D.C. Wu, R.W. Fu, Z.Q. Sun, Z.Q. Yu, J. Non-Cryst. Solids 351, 915 (2005)

S.R. Mukai, C. Tamitsuji, H. Nishihara, H. Tamon, Carbon 43, 2628 (2005)

C. Scherdel, G. Reichenauer, Microporous Mesoporous Mater. 126, 133 (2009)

R. Müller, in Kunststoff-Handbuch 10 Duroplaste, ed. by G.W. Becker, D. Braun (Hanser, München, 1988), p. 622

J. Falbe, M. Regitz, Römpp Chemie Lexikon (Thieme, Stuttgart, 1992)

A. Gardziella, L.A. Pilato, A. Knop, Phenolic Resins (Springer, Berlin, 2000), p. 4

S. Brunauer, P.H. Emmett, E. Teller, JACS 60, 309 (1938)

J. Rouquerol, P. Llewellyn, F. Rouquerol, Stud. Surf. Sci. Catal. 160, 49 (2007)

B.C. Lippens, J.H. De Boer, J. Catal. 4, 319 (1965)

G. Goerigk, H.G. Haubold, O. Lyon, J.P. Simon, J. Appl. Crystallogr. 36, 425 (2003)

P. Debye, H.R. Anderson, H. Brumberger, J. Appl. Phys. 28, 679 (1957)

G. Reichenauer, Adsorption 11, 467 (2005)

G. Porod, Colloid Polym. Sci. 124, 83 (1951)

C. Scherdel, Kohlenstoffmaterialien mit nanoskaliger Morphologie—Entwicklung neuartiger Syntheserouten, Ph.D. Thesis (University Würzburg, 2010)

N. Job, R. Pirard, J. Marien, J.P. Pirard, Carbon 42, 619 (2004)

E. Kumpinsky, Ind. Eng. Chem. Res. 34, 3096 (1995)

B.B. Mandelbrot, The Fractal Geometry of Nature (W. H. Freeman and Company, New York, 1982)

J. Livage, D. Roux, in Nanomaterials and Nanochemistry, ed. by C. Brechignac, P. Houdy, M. Lahmani (Springer, Berlin, 2007), pp. 383–394

R.W. Pekala, D.W. Schaefer, Macromol. 26, 5487 (1993)

R. Zhang, Y. Xu, Y.G. Lu, Z.H. Li, Q.H. Meng, K.X. Li et al., New Carbon Mater. 17, 31 (2002)

R. Zhang, W. Li, K.X. Li, C.X. Lu, L. Zhan, L.C. Ling, Microporous Mesoporous Mater. 72, 167 (2004)

C.J. Gommes, A.P. Roberts, Phys. Rev. E 77, 041409 (2008). doi:10.1103/PhysRevE.77.041409

G. Reichenauer, Stud. Surf. Sci. 160, 351 (2007)

Y. Hanzawa, H. Hatori, N. Yoshizawa, Y. Yamada, Carbon 40, 575 (2002)

N. Nishiyama, T. Zheng, Y. Yamane, Y. Egashira, K. Ueyama, Carbon 43, 269 (2005)

N. Liu, S. Zhang, R. Fu, M.S. Dresselhaus, G. Dresselhaus, Carbon 44, 2430 (2006)

Acknowledgment

This work was supported by the German ministry of research and education (BMBF, FKZ 03X0016D). The authors thank Dr. Guenter Goerigk and Ulla Vainio, PhD from the HASYLAB for their support.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Scherdel, C., Gayer, R., Slawik, T. et al. Organic and carbon xerogels derived from sodium carbonate controlled polymerisation of aqueous phenol-formaldehyde solutions. J Porous Mater 18, 443–450 (2011). https://doi.org/10.1007/s10934-010-9396-y

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10934-010-9396-y