Abstract

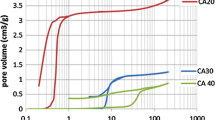

Porous carbons were synthesized from the low cost precursors phenol and formaldehyde in aqueous solution, catalysed with NaOH. The xerogels were ambient pressure dried without prior solvent exchange. For an excess of formaldehyde, the resulting carbon xerogels show porosities up to 90%, with a predominant fraction of macroporosity, specific surface areas up to 768 m2/g and mesopore volumes up to 0.59 cm3/g. Small-angle X-ray scattering reveals fractal behaviour for many samples. Relevant sodium impurities up to 3–4 wt% in the organic and carbon samples cannot be avoided, even by washing of the samples. As possible reason for the high sodium content, the formation of crown ether like calix [6] arene is assumed. Overall, the sodium impurities detected confine the use of this system to applications, where higher ash contents are uncritical.

Similar content being viewed by others

Notes

Source: material safety data sheets from Merck KGaA.

As the pH-value changes when the polymerization reaction proceeds [1], the base or acid used is not a true “catalyst”. However, for convenience, we also denote the base or acid as “catalyst”.

References

R.W. Pekala, J. Mater. Sci. 24, 3221 (1989)

R.W. Pekala, C.T. Alviso, F.M. Kong, S.S. Hulsey, J. Non-Cryst. Solids 145, 90 (1992)

R.W. Pekala, F.M. Kong, J. Phys. 50, C433 (1989)

O. Czakkel, Microporous Mesoporous Mater. 86, 124 (2005)

N. Job, F. Sabatier, J.P. Pirard, M. Crine, A. Leonard, Carbon 44, 2534 (2006)

N. Job, A. Thery, R. Pirard, J. Marien, L. Kocon, J.N. Rouzaud et al., Carbon 43, 2481 (2005)

A. Leonard, N. Job, S. Blacher, J.P. Pirard, M. Crine, W. Jomaa, Carbon 43, 1808 (2005)

T. Yamamoto, T. Nishimura, T. Suzuki, H. Tamon, Dry. Technol. 19, 1319 (2001)

J. Gross, C.T. Alviso, J.K. Nielsen, R.W. Pekala, Mater. Res. Soc. Symp. Proc. 431, 123 (1996)

W.C. Li, S.C. Guo, Carbon 38, 1520 (2000)

W.C. Li, A.H. Lu, S.C. Guo, J. Colloid Interface Sci. 254, 153 (2002)

W.C. Li, G. Reichenauer, J. Fricke, Carbon 40, 2955 (2002)

R.W. Pekala, J. Fricke, in Encyclopedia of Materials, vol. 7, ed. by J. Buschow, R.W. Cahn, M.C. Flemings, B. Ilschner, E. Kramer, S. Mahajan (Elsevier, Amsterdam, 2001), pp. 6502–6506

R. Brandt, Sauer katalysierte, unterkritisch getrocknete Resorcin-Formaldehyd-Aerogele und daraus abgeleitete Kohlenstoff-Aerogele, Ph.D. Thesis (University Würzburg, 2005)

G. Carlson, D. Lewis, K. McKinley, J. Richardson, T. Tillotson, J. Non-Cryst. Solids 186, 372 (1995)

D.C. Wu, R.W. Fu, Z.Q. Sun, Z.Q. Yu, J. Non-Cryst. Solids 351, 915 (2005)

S.R. Mukai, C. Tamitsuji, H. Nishihara, H. Tamon, Carbon 43, 2628 (2005)

C. Scherdel, R. Gayer, T. Slawik, G. Reichenauer, T. Scherb, J. Porous Mater. (2010). doi:10.1007/s10934-010-9396-y

C. Scherdel, G. Reichenauer, Microporous Mesoporous Mater. 126, 133 (2009)

R. Müller, in Kunststoff-Handbuch 10 Duroplaste, ed. by G.W. Becker, D. Braun (Hanser, München, 1988), p. 622

J. Falbe, M. Regitz, Römpp Chemie Lexikon (Thieme, Stuttgart, 1992)

A. Gardziella, L.A. Pilato, A. Knop, Phenolic Resins (Springer, Berlin, 2000)

D.R. Lide, Handbook of Chemistry and Physics, 74th edn. (CRC Press, Boca Raton, 1994), pp. 5-90–5-92

S. Brunauer, P.H. Emmett, E. Teller, JACS 60, 309 (1938)

J. Rouquerol, P. Llewellyn, F. Rouquerol, Stud. Surf. Sci. Catal. 160, 49 (2007)

W.D. Harkins, G. Jura, JACS 66, 1362 (1944)

B.C. Lippens, J.H. De Boer, J. Catal. 4, 319 (1965)

E.P. Barrett, L.G. Joyner, P.P. Halenda, JACS 73, 373 (1951)

G. Goerigk, H.G. Haubold, O. Lyon, J.P. Simon, J. Appl. Crystallogr. 36, 425 (2003)

P. Scherrer, Nachr. Ges. Wiss. Göttingen 2, 98 (1918)

K. Kinoshita, Carbon—Electrochemical and Physicochemical Properties, (Wiley, New York, 1988), chapter 2.1

T. Ko, Polym. Comp. 21, 745 (2000)

A. Gardziella, in Kunststoff-Handbuch 10 Duroplaste, ed. by G.W. Becker, D. Braun (Hanser, München, 1988), chapter 1.2

M.F. Grenier-Loustalot, S. Larroque, P. Grenier, D. Bedel, Polym. 37, 939 (1996)

D.C. Wu, R.W. Fu, S.T. Zhang, M.S. Dresselhaus, G. Dresselhaus, J. Non-Cryst. Solids 336, 26 (2004)

S. Cannizzaro, Justus Liebigs Ann. Chem. 88, 129 (1853)

N. Nishiyama, T. Zheng, Y. Yamane, Y. Egashira, K. Ueyama, Carbon 43, 269 (2005)

R. Brandt, J. Fricke, J. Non-Cryst. Solids 350, 131 (2004)

R. Brandt, R. Petricevic, H. Probstle, J. Fricke, J. Porous. Mater. 10, 171 (2003)

Acknowledgments

This work was supported by the German ministry of research and education (BMBF, FKZ 03X0016). The authors thank Dr. Guenter Goerigk and Ulla Vainio, PhD from the HASYLAB for their support.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Scherdel, C., Gayer, R. & Reichenauer, G. Porous organic and carbon xerogels derived from alkaline aqueous phenol–formaldehyde solutions. J Porous Mater 19, 351–360 (2012). https://doi.org/10.1007/s10934-011-9481-x

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10934-011-9481-x