Abstract

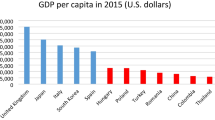

This paper provides novel empirical evidence on productivity growth in the manufacturing sector in Chile, Colombia, Mexico and Peru. Relying on plant-level data, we first decompose productivity and productivity growth into plant-level growth and market allocation forces. While the average productivity of the survivors is higher than the overall contribution of reallocation forces, during recessions the inverse is true and reallocation gives a positive, albeit small, contribution to aggregate productivity growth. Next we analyze how policy measures can determine allocative efficiency levels and growth, and find important scope for action on education, financial regulation, and structural reforms.

Similar content being viewed by others

Notes

We use the term firm or establishment interchangeably even if our empirical analysis will rely on establishment-level information.

This was driven by confidentiality restrictions imposed by the various countries for accessing firm-level data.

Only information on manufacturing firms is available. Furthermore, the Mexican dataset makes it impossible to distinguish between single-product and multi-product firms. It is thus assumed that the observed establishments operate in a single sector.

These statistics are for 2005. In 2009 the survey covers 90% of manufacturing sales in Mexico. The difference is attributable to Maquilladoras, which are excluded from our dataset. After cleaning (see Appendix 1) our dataset contains 70% of total value added in the manufacturing sector in 2009.

This is the threshold for 2012, and it changes yearly on the basis of the producer price index.

Many studies have used this plant level dataset for research purposes (e.g. Pavcnik 2002; Levinsohn and Petrin 2003). The sample covers the quasi-totality of value added in the manufacturing sector as a whole. Even though the information is at the plant level, more than 95% of the plants produced for single-plant firms in 1996, the only year displaying both firm and plant level information.

In 2011 the stratification methodology and the output threshold for firms to be included in the census changed, translating into a decrease in the sample size and in particular in the number of large firms included in the sample. For this reason the dynamic decompositions and econometric analysis below will be restricted to the years 2007–2010.

Until 2007, the EAM was updated on the basis of mini-surveys that were conducted by DANE’s regional offices; starting in 2008, the central DANE cross referenced its sample with other sources of information (Superintendence of Companies, Chambers of Commerce, Free Export Zones, and the exporter’s database).

To be able to compare Colombian, Mexican, and U.S. data in the descriptive statistics, we constructed a conversion table between the SCIAN/NAICS 2002 and ISIC 3.1 classifications. This is discussed in greater detail in the data appendix.

The absence of firm- or plant-specific prices affects the measurement of real output, intermediate consumption, and value added. As described in the Appendix 1, we follow a standard strategy in the literature, and deflate firm-level observables with industry-level price indexes. Real value added can therefore be written as:

$$ VA_{ijt} = \frac{{P_{ijt}^{q} Q_{ijt} }}{{P_{jt}^{q} }} - \frac{{P_{ijt}^{m} M_{ijt} }}{{P_{jt}^{m} }} $$where firm i operates in sector j at time t, and \( P_{.}^{q} \) and \( P_{.}^{m} \) are, respectively, the price charged for one unit of output and paid for one unit of intermediate material inputs. If firm i sells at prices lower than the industry ones, real output is estimated to be lower than it actually is. Similarly, if industry-level prices rose faster than firm-specific ones, the firm’s output growth will be underestimated. The same holds true for material inputs. The bias in the measurement or real value added and labor productivity (growth) will ultimately depend on the correlation between (changes in) price levels of materials and output and their deviation between industry- and firm-level.

The subscript for the country is omitted to simplify the notation.

An important part of the literature computes this decomposition using output instead of employment weights. It is mostly the case, however, that output weights are used when productivity is estimated as total factor productivity (Bartelsman et al. 2009, 2013). As we are focusing our analysis on labor productivity only, we prefer using employment weights. In our context, the weights measure the extent to which the labor input is allocated across plants.

It is still true, however, that decomposing labor productivity rather than TFP cannot account for the differences in capital intensity across firms and countries. These may reflect in differences in the intensity of use and in the cost of labor which profit maximizing firms will adjust to, and in differences between LP- and TFP-based measures of allocative efficiency as a consequence.

Nevertheless, our measure of aggregate productivity remains the result of summing (with weights) plant-level technical efficiencies. Petrin and Levinsohn (2012) show that growth in this measure may substantially differ from aggregate productivity growth calculated as the difference between changes in aggregate final demand and in aggregate expenditure in inputs of production. The implications for aggregate productivity growth and its decomposition are further discussed in the next sessions.

It cannot be excluded that the higher average firm productivity in Mexico is related to the sample composition, which includes relatively bigger firms than in the other countries here analyzed.

We prefer to express the covariance as percentage of aggregate productivity because direct comparisons of their level across sectors could be misleading, due to differences in measurement and sampling across countries (e.g. Bartelsman et al. 2004).

It is indeed the case that, in presence of entry and exit, a change in the static OP covariance may not correspond to a change in allocative efficiency. This happens, for example, when a firm displaying below-mean productivity and below-mean-size exits the market: the covariance term decreases, and the unweighted average productivity increases, but this would not correspond to a “true” reduction in allocative efficiency and increase in within-firm productivity. The proposed dynamic decomposition does not suffer of this caveat.

In light of change in stratification methodology in 2011, the Peruvian sample is restricted to the 2007–2010 period to estimate the dynamic decompositions. Only the decomposition of the growth in productivity levels (rather than log-levels) is proposed. This is coherent with the strategy followed for the static decomposition, itself motivated by Van Biesebroeck (2008).

The choice of using an excluded-country as benchmark has been criticized before. Ciccone and Papaioannou (2007, 2010) show that the further away the benchmark country (in our case, the U.S.) is from the true frictionless economy, the larger the bias towards zero in the policy coefficient. The estimates further suffer from an “amplification” bias, whereby the policy has a stronger (respectively, weaker) effect on the dependent variable for countries which have more similar (resp., different) industrial structure and regulations to the benchmark country ones. The sign of the resulting joint bias is a priori unknown. Ciccone and Papaioannou (2007, 2010) proposed instead to instrument the U.S. industry-level term with cross-country industry and policy information. As a result, the instrumented industry term varies with the “global” component of the U.S. industrial features only, and not with U.S. “idiosyncratic” features. As our sample is composed by few countries, the resulting instrument may be mis-specified and we decided not to follow on this path.

The sample is unbalanced due to the different data access we could obtain across country. In this econometric analysis, we restrict the sample to begin in 2000, in order for at least two countries to always be present. This results in 684 country-industry-year observations, which decrease to 501 in some specifications, due to missing values for the average number of years of schooling in the countries. The dependent variable is taken in hyperbolic log-sine transformation to allow for negative values. The resulting coefficients are therefore interpretable as semi-elasticities. Explanatory variables which are not dummies are standardized over the available years and country-sectors. Errors are both robust and clustered at the industry-country level.

Competition on the product market stimulates innovation, too, although the relationship is often non-linear (Aghion et al. 2004, 2005, 2009). We therefore estimated how changes in regulatory measures correlate to productivity growth, depending on the degree of intensity of sectors in R&D spending (from the OECD ANBERD database), the only proxy of innovation at our disposal. Neither changes in the supply of education, nor in the structural reform index, nor in the financial development indicators of our choice (court interventionism and length of insolvency procedures) were found to significantly change productivity growth differently in R&D intensive vs non-R&D intensive sectors (results available on request). Many an explanation could motivate the lack of statistical correlation. For instance, few firms in each sector invest in R&D, R&D expenditure displays strong serial correlation, or the productivity-enhancing effect of R&D may take time to manifest itself.

The ease of plants to access to credit is negatively correlated to the plants external dependence from finance (see Raddatz 2006).

The index of structural reforms is taken from Lora (2012) and summarizes several policy measures related to competition in the product and input markets. The indicator for product complexity is taken from Nunn (2007) and refers to the percentage of inputs in the industry which are neither traded in organized exchanges nor reference priced. The sectors displaying the highest complexity are: motor vehicles and other transportation equipment, electrical machinery, computers, electronic and optical equipment, and machinery not elsewhere classified; the sectors displaying the lowest complexity are: coke and oil extraction, tobacco, food and beverages, rubber and plastics, and pulp and paper.

For Colombia a more disaggregated producer price index time series was available from 2006 onwards only, at the time of writing.

This is a synthetic sector covering hardware- and software-producing industries, including computer and electronics production, software publishing, telecommunications, data processing, Internet publishing, web portals, computer system designs, and related services.

References

Aghion, P., Bloom, N., Blundell, R., Griffith, R., & Howitt, P. (2005). Competition and innovation: An inverted-U relationship. Quarterly Journal of Economics, 120(2), 701–728.

Aghion, P., Blundell, R., Griffith, R., Howitt, P., & Prantl, S. (2004). Entry and productivity growth: Evidence from microlevel panel data. Journal of the European Economic Association, 2(3), 265–276.

Aghion, P., Blundell, R., Griffith, R., Howitt, P., & Prantl, S. (2009). The effects of entry on incumbent innovation and productivity. The Review of Economics and Statistics, 91(1), 20–32.

Alcalá, F., & Ciccone, A. (2004). Trade and productivity. The Quarterly Journal of Economics, 119(2), 613–646.

Altomonte, C., & Békés, G. (2009). Trade complexity and productivity. KITeS working papers 016.

Amaral, P., & Quintin, E. (2010). Limited enforcement, financial intermediation, and economic development: A quantitative assessment. International Economic Review, 51(3), 785–811.

Andrews, D., & Cingano, F. (2014). Public policy and resource allocation: Evidence from firms in OECD countries. Economic Policy, 29(78), 253–296.

Angrist, J. D., & Pischke, S. (2008). Mostly harmless econometrics: An empiricist’s companion. Princeton: Princeton University Press.

Antras, P., & Helpman, E. (2004). Global sourcing. Journal of Political Economy, 112(3), 552–580.

Antras, P., & Yeaple, S. R. (2014). Multinational firms and the structure of international trade. Handbook of international economics. Elsevier.

Arnold, J. M., Javorcik, B., & Mattoo, A. (2011a). Does service liberalization benefit manufacturing firms? Evidence from the Czech Republic. Journal of International Economics, 85(1), 136–146.

Arnold, J. M., Javorcik, B., & Mattoo, A. (2015). Services reform and manufacturing performance: Evidence from India. The Economic Journal, 126(590), 1–39.

Arnold, J. M., Nicoletti, G., & Scarpetta, S. (2011b). Regulation, resource reallocation and productivity growth. EIB Papers, 16(1), 90–115.

Baily, M. N., Hulten, C., Campbell, D., Bresnahan, T., & Caves, R. E. (1992). Productivity dynamics in manufacturing plants. Brookings papers on economic activity: Microeconomics, pp. 187–267.

Banerjee, A. V., & Duflo, E. (2005). Growth theory through the lens of development economics. In P. Aghion & S. N. Durlauf (Eds.), Handbook of economic growth (Vol. 1, pp. 473–552). Elsevier.

Bartelsman, E., Gautier, P. A., & Wind, J. (2016). Employment protection, technology choice, and worker allocation. International Economic Review, 57, 787–826.

Bartelsman, E., Haltiwanger, J., & Scarpetta, S. (2004). Microeconomic evidence of creative destruction in industrial and developing countries. IZA Discussion Papers 1374, Institute for the Study of Labor (IZA), Bonn, Germany.

Bartelsman, E., Haltiwanger, J., & Scarpetta, S. (2009). Measuring and analyzing cross-country differences in firm dynamics. In T. Dunne, J. Bradford Jensen, & M. J. Roberts (Eds.), Producer dynamics: New evidence from micro data (pp. 15–76). Chicago: University of Chicago Press.

Bartelsman, E., Haltiwanger, J., & Scarpetta, S. (2013). Cross-country differences in productivity: The role of allocation and selection. American Economic Review, 103(1), 305–334.

Barth, J. R., Caprio, G., & Levine, R. (2012). The evolution and impact of bank regulations. Policy Research Working Paper No. 6288. World Bank.

Bassanini, A., Nunziata, L., & Venn, D. (2009). Job protection legislation and productivity growth in OECD countries. Economic Policy, 24(58), 349–402.

Bloom, N., Draca, M., & van Reenen, J. (2016). Trade induced technical change? The impact of Chinese imports on innovation, IT and productivity. Review of Economic Studies, 83(1), 87–117.

Bourlès, R., Cette, G., Lopez, J., Mairesse, J., & Nicoletti, G. (2013). Do product market regulations in upstream sectors curb productivity growth? Panel data evidence For OECD countries. The Review of Economics and Statistics, 95(5), 1750–1768.

Bravo-Biosca, A., Criscuolo, C., & Menon, C. (2016). What drives the dynamics of business growth? Economic Policy, 31(88), 703–742.

Buera, F. J., Kaboski, J. P., & Shin, Y. (2011). Finance and development: A tale of two sectors. American Economic Review, 101(5), 1964–2002.

Byrne, D., Fernald, J., & Reinsdorf, M. (2016). Does the United States have a productivity slowdown or a measurement problem? Brookings Papers on Economic Activity.

Ciccone, A., & Papaioannou, E. (2007). Red tape and delayed entry. Journal of the European Economic Association, 5(2–3), 444–458.

Ciccone, A., & Papaioannou, E. (2010). Estimating cross-industry cross-country models using benchmark industry characteristics. Economics Working Papers No 504, Department of Economics and Business, Universitat Pompeu Fabra.

Cristea, A., Hummels, D., Puzzello, L., & Avetisyan, M. (2013). Trade and the greenhouse gas emissions from international freight transport. Journal of Environmental Economics and Management, 65(1), 153–173.

Davis, S. J., & Haltiwanger, J. (1992). Gross job creation, gross job destruction, and employment reallocation. The Quarterly Journal of Economics, 107(3), 819–863.

de la Fuente, A. (2010). Infrastructures and productivity: An updated survey. UFAE and IAE Working Papers 831.

Decker, R., Haltiwanger, J., Jarmin, R. S., & Miranda, J. (2017). Declining dynamism, allocative efficiency, and the productivity slowdown. American Economic Review, 107(5), 322–326.

Delgado, M., Henderson, D. J., & Parmeter, C. F. (2014). Does education matter for economic growth? Oxford Bulletin of Economics and Statistics, 76(3), 334–359.

Eaton, J., Kortum, S., & Kramarz, F. (2011). An anatomy of international trade: Evidence from French firms. Econometrica, 79(5), 1453–1498.

Fernald, J. (2015). Productivity and potential output before, during and after the great recession. NBER Macroeconomics Annual, 29(1), 1–51.

Foster, L., Grim, C., & Haltiwanger, J. (2016a). Reallocation in the great recession: Cleansing or not? Journal of Labor Economics, 34(S1), S293–S331.

Foster, L., Grim, C., Haltiwanger, J., & Wolf, Z. (2016b). Firm-level dispersion in productivity: Is the devil in the details? American Economic Review, American Economic Association, 106(5), 95–98.

Foster, L., Haltiwanger, J., & Krizan, C. J. (2001). Aggregate productivity growth. Lessons from microeconomic evidence. In C. R. Hulten, E. R. Dean, & M. J. Harper (Eds.), New developments in productivity analysis (pp. 303–372). Chicago: University of Chicago Press.

Foster, L., Haltiwanger, J., & Syverson, C. (2008). Reallocation, firm turnover, and efficiency: Selection on productivity or profitability? American Economic Review, 98(1), 394–425.

Foster, L., Haltiwanger, J., & Syverson, C. (2016c). The slow growth of new plants: Learning about demand? Economica, 83(329), 91–129.

Gómez-Salvador, R., Messina, J., & Vallanti, G. (2004). Gross job flows and institutions in Europe. labor Economics, 11(4), 469–485.

Grossman, G. M., & Helpman, E. (2003). Outsourcing versus FDI in industry equilibrium. Journal of the European Economic Association, 1(2–3), 317–327.

Griliches, Z., & Haim, R., (1995). Firm productivity in Israeli industry 1979–1988. Journal of Econometrics, 65(1), 175–203.

Haltiwanger, J., Kulick, R. B., & Syverson, C. (2018). Misallocation measures: The distortion that ate the residual. NBER Working Paper N. 24199.

Haltiwanger, J., Scarpetta, S., & Schweiger, H. (2014). Cross country differences in job reallocation: The role of industry, firm size and regulations. labor Economics, 26(C), 11–25.

Harrison, A. E., Martin, L. A., & Nataraj, S. (2013). Learning versus stealing: How important are market-share reallocations to India’s productivity growth? World Bank Economic Review, 27(2), 202–228.

Hsieh, C. T., & Klenow, P. J. (2009). Misallocation and manufacturing TFP in China and India. Quarterly Journal of Economics, 124(4), 1403–1448.

Inter-American Development Bank. (2010). The age of productivity. Washington, DC: Palgrave MacMillan.

International Monetary Fund. (2014). Regional economic outlook update: Western hemisphere—Latin America and the Caribbean. Technical Report.

Le Mouel, M., Marcolin, L., & Squicciarini, M. (2016). Investment in organisational capital: Methodology and panel estimates. SPINTAN Working Paper, p. 21.

Levinsohn, J., & Petrin, A. (2003). Estimating production functions using inputs to control for unobservables. The Review of Economic Studies, 70(2), 317–341.

Lileeva, A., & Trefler, D. (2010). Improved access to foreign markets raises plant-level productivity for some plants. Quarterly Journal of Economics, 125(3), 1051–1099.

Lora, E. (2012). Structural reforms in Latin America: What has been reformed and how to measure it (updated version). Inter-American Development Bank Working Paper Series, p. 346.

Madsen, J. B. (2014). Human capital and the world technology frontier. The Review of Economics and Statistics, 96(3), 676–692.

McGowan, M. A., & Andrews, D. (2015). Skill mismatch and public policy in OECD Countries. OECD Economics Department Working Papers 1210, OECD Publishing.

Melitz, M. J. (2003). The impact of trade on intra-industry reallocations and aggregate industry productivity. Econometrica, Econometric Society, 71(6), 1695–1725.

Melitz, M. J., & Polanec, S. (2015). Dynamic Olley–Pakes productivity decomposition with entry and exit. The Rand Journal of Economics, 46(2), 362–375.

Midrigan, V., & Xu, D. Y. (2014). Finance and misallocation: Evidence from plant-level data. American Economic Review, 104(2), 422–458.

Nicoletti, G., & Scarpetta, S. (2003). Regulation, productivity and growth: OECD evidence. Economic Policy, 18(36), 9–72.

Nishida, M., Petrin, A., & Polanec, S. (2014). Exploring reallocation’s apparent weak contribution to growth. Journal of Productivity Analysis, 42, 187–210.

Nishida, M., Petrin, A., Rotemberg, M., & White, T. K. (2013). Are we undercounting reallocation’s contribution to growth? Working Papers 13-55r, Center for Economic Studies, U.S. Census Bureau.

Nunn, N. (2007). Relationship-specificity, incomplete contracts and the pattern of trade. Quarterly Journal of Economics, 122(2), 569–600.

Olley, G. S., & Pakes, A. (1996). The dynamics of productivity in the telecommunications equipment industry. Econometrica, 64(6), 1263–1297.

Pages, C., Pierre, G., & Scarpetta, S. (2009). Job creation in Latin America: Recent trends and policy challenges. Washington, DC: World Bank.

Pavcnik, N. (2002). Trade liberalization, exit, and productivity improvements: Evidence from Chilean plants. Review of Economic Studies, 69(1), 245–276.

Petrin, A., & Levinsohn, J. (2012). Measuring aggregate productivity growth using plant level data. The Rand Journal of Economics, 43(4), 705–725.

Prichett, L. (2006). Does learning to add up add up? The returns to schooling in aggregate data. In E. Hanushek, F. Welch (Eds.), Handbook of the economics of education (Vol. 1). North Holland.

Raddatz, C. (2006). Liquidity needs and vulnerability to financial underdevelopment. Journal of Financial Economics, 80(3), 677–722.

Rajan, R. G., & Zingales, L. (1998). Financial dependence and growth. American Economic Review, 88, 559–586.

Restuccia, D., & Rogerson, R. (2008). Policy distortions and aggregate productivity with heterogeneous plants. Review of Economic Dynamics, 11(4), 707–720.

Restuccia, D., & Rogerson, R. (2013). Misallocation and productivity. Review of Economic Dynamics, 16(1), 1–10.

Sarriera, J. M., Serebrisky, T., Araya, G., Briceño-Garmendia, C., & Schwartz, J. (2013). Benchmarking container port technical efficiency in Latin America and the Caribbean. IDB Working Paper Series 474.

Sianesi, B., & Van Reenen, J. (2003). The returns to education: Macroeconomics. Journal of Economic Surveys, 17, 157–200.

Straub, S. (2008). Infrastructure and growth in developing countries: Recent advances and research challenges. World Bank Policy Research Working Paper 4460.

Syverson, C. (2004). Product substitutability and productivity dispersion. Review of Economics and Statistics, 86(2), 534–550.

Syverson, C. (2008). Markets: Ready-mixed concrete. Journal of Economic Perspectives, 22(1), 217–234.

Syverson, C. (2017). Challenges to mismeasurement explanations for the US productivity slowdown. Journal of Economic Perspectives, 31(2), 165–186.

Van Biesebroeck, J. (2008). Aggregating and decomposing productivity. Review of Business and Economics, 53(2), 122–146.

Vandenbussche, J., Aghion, P., & Meghir, C. (2006). Growth, distance to frontier and composition of human capital. Journal of Economic Growth, 11(2), 97–127.

Yu, M., Ye, G., & Qu, B. (2013). Trade liberalisation, product complexity and productivity improvement: Evidence from Chinese firms. The World Economy, 36(7), 912–934.

Acknowledgements

The present analysis expresses only the authors’ views and does not necessarily reflect the official views of the institutions where the authors are affiliated. The authors retain all responsibilities for errors and omissions in this document. We are very grateful to Nathalie Gonzalez, Camilo Gutierrez Silva, Lucas Navarro, and Trang Thu Tran for their assistance in the cleaning of the country micro-level datasets and the implementation of the analytical code. We would also like to sincerely thank Giuseppe Berlingieri, Chiara Criscuolo, Joze Damijan, Jozef Konings, Mariagrazia Squicciarini, Otto Toivanen, Stijn Vanormelingen, and the participants to the 2014 EIED conference for the insightful discussions and feedback throughout the elaboration of this paper.

Author information

Authors and Affiliations

Corresponding author

Appendices

Appendix 1: Micro data construction

We have access to establishment-level panel data setsfor Chile (Encuesta National Industrial Annual—ENIA), Colombia (Encuesta Anual Manufacturera, EAM), Mexico (Encuesta Industrial Anual, EIA), as well as a firm-level panel of firms in Peru (Encuesta Económica Annual, EEA). This was possible thanks to the respective national institutes of statistics (DANE, INE, INEI, INEGI). These data sets contain accounting information on plants in the manufacturing sector for 1995–2007 for Chile, 2000–11 for Colombia, 2003–11 for Mexico, 2007–2012 for Peru. In this annex, we supplement the information on eligibility and coverage of the manufacturing surveys that was provided in the main text.

1.1 Data cleaning

As our analysis requires non-missing observations for value added and employment in particular, we dropped all observations without information for value added per employee and industry classification, as well as those reporting negative employment and value added. In a further effort to limit the extent of misreporting, we also dropped observations with positive value added but zero employment; as a consequence, we excluded the possibility of sole proprietorship, which we deemed more unlikely in manufacturing. We treated the presence of extreme values in the resulting sample by truncating the distribution of value added and growth in value added at 1 and 99%.

As value added was not directly reported in the data set, we constructed it as the sum between (deflated) revenues from sales, minus the (deflated) cost of raw (either domestic or imported) materials and the (deflated) cost of electricity. If any component of this sum is missing, the result is also missing.

The resulting sample has missing values for the Chilean Tobacco sector, the Colombian Office Equipment production sector, the Mexican Transportation Equipment sector, and the Tobacco, Oil, and Office, Communication and Medical Equipment producing sectors.

1.2 Industry classification and conversion

Each of the micro-level surveys used in this study follows a different industry classification. The Chilean ENIA, Colombian EAM and Peruvian EEA classify manufacturing plants according to a four-digit International Standard Industrial Classification (ISIC3 or ISIC4) classification specifically adapted to the Chilean and Colombian context, containing respectively 113, 142 and 125 sectors. The Mexican EIA uses a six-digit classification inspired by the North American Industry Classification System (NAICS) for 2002 and 2007 (Système de classification des industries de l’Amérique du Nord (SCIAN) 2002 and 2007), displaying 231 industries.

The use of different industry classifications would have hindered the cross-country comparison of descriptive statistics and productivity decompositions. We created a new industry classification for manufacturing, which could include all national classifications, on the basis of existing NAICS 2002-NAICS 2007, NAICS-SCIAN, ISIC3 (Colombia)-ISIC 3.1 (international), ISIC3.1-ISIC4 (international) and NAICS 2002-ISIC3.1 (international) conversion tables. The resulting classification we use contains 104 4-digit classes and is broadly inspired by the international ISIC 3.1 breakdown.

One ISIC 3.1 four-digit class and seven six-digit NAICS 2002 classes have no correspondence in the new classification.

In constructing this new industrial classification, we first converted the national classifications into either NAICS 2002 or ISIC 3.1. A one-to-many correspondence between a four-digit ISIC 3.1 and a six-digit NAICS 2002 code also resulted in the use of the ISIC 3.1 code (this happened for 281 of 473 U.S. NAICS manufacturing classes). In taking into consideration the numerous many-to-many correspondences between NAICS 2002 and ISIC 3.1, we followed these principles:

-

1.

When one of the multiple ISIC 3.1 codes corresponding to a single NAICS 2002 code was not classified as manufacturing in the ISIC 3.1 classification, we dropped this ISIC 3.1 code altogether. This happened for eight six-digit NAICS codes.

-

2.

When the NAICS 2002 classification was specific enough, we searched for the corresponding products in the ISIC 3.1. A description table for the ISIC 3.1 code can be found at http://unstats.un.org/unsd/statcom/doc02/isic.pdf.

-

3.

When in doubt about the attribution of a certain six-digit NAICS code to an ISIC code, we also took into consideration the meaning of the five- and four-digit NAICS codes.

-

4.

When the “predominant meaning” of an NAICS code was clear once aggregating two or more of the proposed four-digit ISIC codes in the NAICS-ISIC conversion table, we merged the different ISIC codes. We limited the number of cases in which this happened, as it reduced the number of final available industry codes. In most cases, the merged ISIC codes refer to the same two- or three-digit ISIC classes.

-

5.

We dropped seven NAICS six-digit codes, whose meaning could not be linked to any single ISIC or combination of ISIC codes.

1.3 Deflation

All financial information in the different manufacturing surveys is reported in nominal terms. We therefore deflate these values with an appropriate deflator in base 2005. We then convert them to thousands of U.S. dollars using the appropriate (yearly) exchange rate from the World Bank.

To deflate sales we use six-digit producer index prices for Mexico, 4 digit ones for Chile, and a manufacturing-level producer price index for Colombia and Peru.Footnote 25 For material inputs, we use the appropriate four-digit producer price index for Chile and for Mexico (the latter based on the CMAE—classification—Catálogo Mexicano de Actividades Económicas), and a manufacturing-wide deflator for Colombia and Peru. Expenditure for electricity, was deflated using the producer price index for the electricity sector in all countries but Peru, where this expenditure is not available. Finally, we used the consumer price index to deflate labor costs.

For Colombia and Mexico capital investment is deflated using three-digit price indexes for investment from the U.S. Bureau of Labor Statistics (BLS), which we adjust by the exchange rate between US$ and the country currency. The BLS provides prices deflators for different types of investment: all capital goods, equipment, structures, land, intellectual property products, and inventories. We exploit the first three prices for, respectively, all investments, investment in machinery, and investment in buildings. Where available information and communications technology (ICT) capital investment was deflated using the price of gross output for the “information-communications-technology-producing industries” elaborated by the Bureau of Economic AnalysisFootnote 26 and adjusted by the exchange rate. We deflated investment in transportation equipment by the country-specific producer price index for the transportation sector.

1.4 Variable construction

The ideal measure of the capital stock embodied in the plants’ production would be the replacement value of capital. Unfortunately, this is not available in the micro-data surveys we have access to. We create instead a measure of the plants’ capital stock at book value, i.e. the depreciated value at which capital assets were purchased. We assume that the book value in the first year of the sample corresponds to the capital replacement value. We then construct the value of capital for the following years using the perpetuary inventory method (PIM) according to the following equality:

For \( t \in \left[ {1995, 2007} \right] \) for Chile, \( t \in \left[ {2001, 2011} \right] \) for Colombia, \( t \in \left[ {2004, 2011} \right] \) for Mexico. \( I_{ijt - 1} \) denotes investment, or the purchase of new capital goods (which is reported in the data sets), and \( K_{ijt} \) is the result of the calculation of capital stocks in the year. \( \delta_{jt} \) is the depreciation rate of capital. All surveys considered contain information on depreciation rates by type of capital. To limit the impact of possible misreporting, in the PIM we use the median of the two-digit sector depreciation rate from the data, where values above 100% and below 0% of capital stock were winsorized. Once we obtained a time series for the capital stock of each type of capital (buildings, equipment, ICT, and transportation, if available), we aggregated them into two variables, one for total capital and another for total capital except buildings and structures.

Appendix 2: Industry- and country-level framework data

The table below summarises the information exploited by this analysis in terms of policy levers potentially affecting allocative efficiency and average firm productivity in the economy, as well as the degree of exposure of manufacturing industries to those policies.

Variable | Definition | Source |

|---|---|---|

Country level | ||

Court involvement | The degree to which the banking supervisory authority is independent from court rulings. The higher this index is, the less independent the supervisory authority is | Barth et al. (2012) |

Accounting practices | The type of accounting practices used (the higher the better) | Barth et al. (2012) |

Resolving insolvency | Years needed to resolve insolvency | World Bank Doing Business |

Years of schooling | Years of schooling for population older than 25 year-old | UNESCO |

Cost of firing | Expected cost of firing (number of months) | Lora (2012) |

Structural reform index | Structural reform index. The higher, the more liberalised the country is | Lora (2012) |

Port efficiency | Technical efficiency of container ports | Sarriera et al. (2013) |

Industry level (USA) | ||

Tangibility | Sum of fixed assets and depreciation, divided by operating revenues. Median value among firms in the industry, 2000 | ORBIS© |

Financial dependence | Capital expenditure not funded by internal funds divided by total capital expenditure | Rajan and Zingales (1998) |

Low-skill intensity | Share of industry’s workforce with low-skilled occupation (ILO-based) | U.S. CPS |

Capital intensity | Total capital assets in the industry over employment | OECD STAN |

Product complexity | Proportion of industry’s value added which is priced neither through organized markets nor with reference prices (conservative approach). Values were converted from ISIC2 to ISIC3 using value added shares and the appropriate conversion table | Nunn (2007) |

Organisational capabilities | Industry’s investment in organizational capital divided by output. Investment is the sum over the wage bill of the industry’s employees who are performing organizational-intensive tasks on the job place | Le Mouel et al. (2016), OECD STAN |

Share of trade by sea | Share of trade value added in the industry transported by sea | Cristea et al. (2013) |

Rights and permissions

About this article

Cite this article

Brown, J.D., Crespi, G.A., Iacovone, L. et al. Decomposing firm-level productivity growth and assessing its determinants: evidence from the Americas. J Technol Transf 43, 1571–1606 (2018). https://doi.org/10.1007/s10961-018-9678-0

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10961-018-9678-0