Abstract

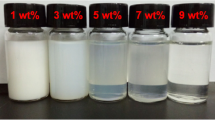

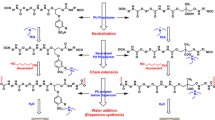

A series of maleated cottonseed oil polyol (MAHCSO) based, DMPA (dimethylol propionic acid) free, catalyst free waterborne polyurethane dispersions (PUDs) were synthesized. Four different tertiary amines, were employed as neutralizing agents to investigate the role of countercation on the physico-chemical properties of PUDs and their corresponding cured films. The developed PUDs were characterized by particle size analysis, zeta potential distribution, viscosity and storage stability and the cured film samples were characterized by FT-IR (ATR), DMTA (Dynamic mechanical and thermal analysis), UTM (Universal testing machine) and contact angle analyses. It was found that the waterborne PUD with countercation having more number of hydroxy alkyl chains exhibit a larger particle size, a less negative zeta potential, higher viscosity and lower storage stability, where as the corresponding cured film possesses lower thermal stability, mechanical strength and poor surface properties.

Synopsis: Cottonseed oil based ionisable polyol was synthesized by insitu ring opening hydrolysis of epoxy cotton seed oil (ECSO) followed by maleanisation to introduce carboxylic groups. The maleated polyol was used as ionic soft segment to synthesize four types of waterborne polyurethane dispersions (PUDs) using different neutralizing agents.

Similar content being viewed by others

References

Gonzalez-Alvarez MJ, Paternoga J, Breul K, Cho H, Roshandel MZ, Soleimani M, Winnik MA (2017) Understanding particle formation in surfactant-free waterborne coatings prepared by emulsification of pre-formed polymers. Polym Chem 8(19):2931–2941. https://doi.org/10.1039/C7PY00387K

Gogoi S, Karak N (2014) Biobased biodegradable waterborne hyperbranched polyurethane as an ecofriendly sustainable material. ACS Sustain Chem Eng 2(12):2730–2738. https://doi.org/10.1021/sc5006022

Santamaria-Echart A, Ugarte L, García-Astrain C, Arbelaiz A, Corcuera MA, Eceiza A (2016) Cellulose nanocrystals reinforced environmentally-friendly waterborne polyurethane nanocomposites. Carbohydr Polym 151:1203–1209. https://doi.org/10.1016/j.carbpol.2016.06.069

Xia Y, Larock RC (2011) Soybean oil–isosorbide-based waterborne polyurethane–urea dispersions. ChemSusChem 4(3):386–391. https://doi.org/10.1002/cssc.201000411

Wang H, Zhou Y, He M, Dai Z (2015) Effects of soft segments on the waterproof of anionic waterborne polyurethane. Colloid Polym Sci 293(3):875–881. https://doi.org/10.1007/s00396-014-3472-9

Zhang C, Madbouly SA, Kessler MR (2015) Biobased polyurethanes prepared from different vegetable oils. ACS Appl Mater Interfaces 7(2):1226–1233. https://doi.org/10.1021/am5071333

Meier MA, Metzger JO, Schubert US (2007) Plant oil renewable resources as green alternatives in polymer science. Chem Soc Rev 36(11):1788–1802. https://doi.org/10.1039/B703294C

Lu Y, Larock RC (2009) Novel polymeric materials from vegetable oils and vinyl monomers: preparation, properties, and applications. ChemSusChem 2(2):136–147. https://doi.org/10.1002/cssc.200800241

Khanderay JC, Gite VV (2017) Vegetable oil-based polyurethane coatings: recent developments in India. Green Mater 1─14. https://doi.org/10.1680/jgrma.17.00009

Bakhshi H, Yeganeh H, Mehdipour-Ataei S, Solouk A, Irani S (2013) Polyurethane coatings derived from 1, 2, 3-triazole-functionalized soybean oil-based polyols: studying their physical, mechanical, thermal, and biological properties. Macromolecules 46(19):7777–7788. https://doi.org/10.1021/ma401554c

Islam MR, Beg MDH, Jamari SS (2014) Development of vegetable-oil-based polymers. J Appl Polym Sci 131(18). https://doi.org/10.1002/app.40787

Petrović ZS, Cvetković I, Hong D, Wan X, Zhang W, Abraham TW, Malsam J (2010) Vegetable oil-based triols from hydroformylated fatty acids and polyurethane elastomers. Eur J Lipid Sci Technol 112(1):97–102. https://doi.org/10.1002/ejlt.200900087

Guo A, Cho Y, Petrović ZS (2000) Structure and properties of halogenated and nonhalogenated soy-based polyols. J Polym Sci A Polym Chem 38(21):3900–3910. https://doi.org/10.1002/1099-0518(20001101)38:21<3900::AID-POLA70>3.0.CO;2-E

Petrović ZS, Zhang W, Javni I (2005) Structure and properties of polyurethanes prepared from triglyceride polyols by ozonolysis. Biomacromolecules 6(2):713–719. https://doi.org/10.1021/bm049451s

Hao N, Wu J, Wan J, Liu Z (2017) Morphology and mechanical properties of UV-curable castor oil-based waterborne polyurethane/organic montmorillonite nanocomposites. Plast Rubber Compos 46(8):346–354. https://doi.org/10.1080/14658011.2017.1356974

Athawale VD, Nimbalkar RV (2011) Polyurethane dispersions based on sardine fish oil, soybean oil, and their interesterification products. J Dispers Sci Technol 32(7):1014–1022. https://doi.org/10.1080/01932691.2010.497459

Saalah S, Abdullah LC, Aung MM, Salleh MZ, Biak DRA, Basri M, Jusoh ER (2015) Waterborne polyurethane dispersions synthesized from jatropha oil. Ind Crop Prod 64:194–200. https://doi.org/10.1016/j.indcrop.2014.10.046

Kim B, Yang J, Yoo S, Lee J (2003) Waterborne polyurethanes containing ionic groups in soft segments. Colloid Polym Sci 281(5):461–468. https://doi.org/10.1007/s00396-002-0799-4

Yang CZ, Grasel TG, Bell JL, Register RA, Cooper SL (1991) Carboxylate-containing chain-extended polyurethanes. J Polym Sci Polym Phys 29(5):581–588. https://doi.org/10.1002/polb.1991.090290507

Bao LH, Lan YJ, Zhang SF (2006) Synthesis and properties of waterborne polyurethane dispersions with ions in the soft segments. J Polym Res 13(6):507–514. https://doi.org/10.1007/s10965-006-9073-7

Chen R, Zhang C, Kessler MR (2014) Anionic waterborne polyurethane dispersion from a bio-based ionic segment. RSC Adv 4(67):35476–35483. https://doi.org/10.1039/C4RA07519F

KosheelaDevi PP, Tuan Noor Maznee TI, Hoong SS, Nurul'Ain H, Norhayati MN, Srihanum A et al (2016) Performance of palm oil-based dihydroxystearic acid as ionizable molecule in waterborne polyurethane dispersions. J Appl Polym Sci 133(27). https://doi.org/10.1002/app.43614

Gaddam SK, Palanisamy A (2016) Anionic waterborne polyurethane dispersions from maleated cotton seed oil polyol carrying ionisable groups. Colloid Polym Sci 294(2):347–355. https://doi.org/10.1007/s00396-015-3787-1

Gaddam SK, Kutcherlapati SR, Palanisamy A (2017) Self-cross-linkable anionic waterborne polyurethane–silanol dispersions from cottonseed-oil-based phosphorylated Polyol as ionic soft segment. ACS Sustain Chem Eng 5(8):6447–6455. https://doi.org/10.1021/acssuschemeng.7b00327

Vogel AI, Tatchell AR, Furnis BS, Hannaford AJ, Smith PWG (1996) Vogel’s text book of practical organic chemistry5th edn. ELBS, London, p 703

Kumar Gaddam S, Palanisamy A (2017) Anionic waterborne polyurethane-imide dispersions from cottonseed oil based ionic polyol. Ind Crop Prod 96:132–139. https://doi.org/10.1016/j.indcrop.2016.11.054

Perez-Liminana MA, Aran-Ais F, Torró-Palau AM, Orgilés-Barceló AC, Martín-Martínez JM (2005) Characterization of waterborne polyurethane adhesives containing different amounts of ionic groups. Int J Adhes Adhes 25(6):507–517. https://doi.org/10.1016/j.ijadhadh.2005.02.002

Nanda AK, Wicks DA, Madbouly SA, Otaigbe JU (2005) Effect of ionic content, solid content, degree of neutralization, and chain extension on aqueous polyurethane dispersions prepared by prepolymer method. J Appl Polym Sci 98(6):2514–2520. https://doi.org/10.1002/app.22141

Li X, Hu J, Sun D, Zhang Y (2014) Nanosilica reinforced waterborne siloxane-polyurethane nanocomposites prepared via “click” coupling. J Coat Technol Res 11(4):517–531. https://doi.org/10.1007/s11998-013-9563-6

Acknowledgements

The authors gratefully acknowledge financial support for this work from the CSIR XII five-year-plan project “INTELCOAT” (CSC 0114). One of the authors Sashivinay Kumar Gaddam acknowledges the Council of Scientific and Industrial Research (CSIR) for granting a Senior Research Fellowship [Award 17-06/2012(i)EU-V].

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Gaddam, S.K., Palanisamy, A. Effect of counterion on the properties of anionic waterborne polyurethane dispersions developed from cottonseed oil based polyol. J Polym Res 25, 186 (2018). https://doi.org/10.1007/s10965-018-1580-9

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10965-018-1580-9