Abstract

Phosphogypsum (PG) is a residue of the phosphate fertilizer industry that has relatively high concentrations of harmful radioactive materials. The reduction in concentration of the radionuclides from PG was investigated. The removal process is based on leaching of radionuclides using suitable organic extractants. The studied radionuclides were 226Ra, 210Pb, 238U and 40K. The factors affect the leaching process such as type of leaching materials, contact time, concentration of the desired solvent, liquid to solid ratio, and temperature were studied. Based on the experimental results, about 71.1, 76.4, 62.4, and 75.7% of 226Ra, 210Pb, 238U and 40K respectively were successfully removed from the PG. The reduction in the concentration of radionuclides was accompanied by reduction in the concentration of rare earth elements (∑REE) equals to 69.8%. Using the desired organic extractant under optimum conditions for treatment of the PG waste leads to obtain a decontaminated product that can be safely used in many industrial applications.

Similar content being viewed by others

Introduction

Many important industries such as manufacture of wallboard, plaster of Paris, blackboard, chalk and roadwork were based on gypsum. The gypsum is generally used to include all substances of calcium sulfate, whatever the amount of water of crystallization. A number of types of gypsum products [such as phosphogypsum (PG)] are used allover the world [1]. PG is a by-product in the manufacture of phosphoric acid by acidulation of phosphate rock with 70% sulfuric acid as in the following reaction:

The amount of PG exceeds the mass of the product, because this amount was produced in the ranges from 4.5 to 5.5 tons per ton P2O5 in terms of dry matter depending on the method of production. This PG is mostly disposed off without any treatment, which represents serious disposal problems with the phosphoric acid production unit. In totally new building products, such as cements, enormous amounts of PG could be used [2, 3].

Phosphogypsum is a technologically enhanced naturally occurring radioactive material (TE-NORM) that contains radionuclides from 238U and 232Th decay series which are of most radiotoxicity. Rare earth elements and barium are also enriched in the PG [1]. Lokshin et al. [4]. mentioned that during production of phosphoric acid with sulfuric acid, the main part of lanthanides passes to CaSO4·2H2O phase. PG contains relatively high amounts of 226Ra that decays into 222Rn through α-transformation. Radon exhalation from PG may pose a health risk to workers on a stack or people living in houses equipped with PG panels [5–8].

Until now only a few papers have been published on the solvent extraction of radium. A method for the extraction of radium into a mixture of 2-thenoyltrifluoroacetone (HTTA) and tributyl phosphate (TBP) or trioctylphosphine oxide (TOPO) in n-hexane or cyclohexane with regard to the pH, TBP and TOPO concentrations was studied. The formation of mixed complexes of Ra(TTA)2(TBP)2 and Ra(TTA)2(TOPO)2 occurs and the overall extraction constants of both complexes were calculated. The results show that the substitution of n-hexane by cyclohexane has practically no effect on the extraction of radium and the more electronegative TOPO is much more effective than TBP. Further, n-hexane or cyclohexane is more suitable solvents than CCl4 [9, 10]. The extraction of radium and barium into a mixture of 1-phenyl-3-methyl-4-benzoylpyrazol-5-one (HPy) and TOPO in n-hexane or cyclohexane as a function of pH and TOPO concentration was investigated. It was found that the synergistic enhancement of the extraction is caused by the formation of mixed complexes of M(Py)2(TOPO)3. From the calculation of the overall extraction constants of both complexes, the extraction of barium is higher than that of radium and the theoretical separation factor of (Ba/Ra) is equal to 4.6 and 8.5 for n-hexane and cyclohexane, respectively [11].

El-Afifi et al. [12] performed physical and chemical treatment on PG containing 226Ra. The physical treatment was based on the particle size separation (dry and wet fractionation), whereas the chemical treatment was carried out using leaching solutions (single and sequential leaching processes). The results showed that the particle size separation affected the distribution of radionuclides in PG. High enrichment factors were obtained in the wet fractionation which equal 3.1 and 3.9 compared to the PG bulk for 226Ra and 210Pb respectively. The chemical leaching conditions of PG waste were optimized. In the single chemical leaching, 40% of total 226Ra in PG was removed, while about 87% of 226Ra was removed in the sequential leaching.

The present work aims to purify the PG, a by-product from the wet process phosphoric acid in Egypt, and to minimize the environmental pollution during storage, transportation and usage. The main goal is to decrease its radioactive nuclides such as 226Ra, 210Pb, 238U, and 40K to the acceptable level using suitable and commercial organic extractants. The extracted radionuclides can be easily recovered from the solvent and introduced in many useful processes. The decontaminated product can be safely used in many industrial applications to prepare low cost products.

Experimental

Materials and apparatus

Samples of PG (of density equals 2.29 g/cm3) were provided from the Sebaiya rock, Red Sea Coast, Egypt, by (the wet process phosphoric acid plant) Abu-Zaabal Company for Fertilizers and Chemicals. TBP, trioctyl phosphine oxide (TOPO), triphenyl phosphine oxide (TPPO), and di-ethyl-hexyl phosphoric acid (DEHPA) were provided by Loba Chemie PVT. LTD, as well as kerosene, benzene, toluene, and n-hexane were provided by El-Nasr Chemicals Company, Egypt. Metertech UV/VIS SP8001 Spectrophotometer, China, was used for measuring the concentrations of major oxides, fluorine, uranium, thorium and total rare earth elements (∑REE) [13, 14]. The γ-ray spectrometer was used for radiometric determination of radionuclides. The different radionuclides in PG samples were identified and quantified using HPGe detector (2201-Oxford, USA, the detector was shielded by lead shield) with relative efficiency of 30% and resolution (FWHM) of 1.95 keV at 1.332 MeV for 60Co. The counting time is 7,200 s (2 h). The uncertainty of the measurements was about ±7% for all radionuclides. The acquisition spectra were processed by 8 k MCA and Genie 2000 software (MCA with 8192-channel is connected with IBM personal computer). Energy calibration was performed using several certified sealed point sources of known γ-energy lines, namely, 22Na, 60Co, 133Ba and 137Cs (Amersham, England). The efficiency as a function of the γ-energy (in keV) for the HPGe detector was determined using reference materials (IAEA 312, 313 and 314) with known activity concentrations provided by the Analytical Quality Control Services (AQCS), International Atomic Energy Agency (IAEA), Vienna, Austria [15–17].

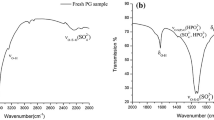

An accurate 50 g of PG was stored in plastic container for radiometric measurements. Activity concentrations of 226Ra, 238U, 210Pb and 40K in the PG were determined from the measured net count rate (c/s) of 186.2 keV (yield per decay of 3.3%), 352 keV (37.1%), 46.2 keV (4%), and 1461 keV (10.7%) respectively. A spectrum containing the peaks of the investigated nuclides was shown in Fig. 1.

Analysis of the phosphogypsum

Morphologically, the PG is yellowish brown color and relatively soft grains [18–20]. Chemically, the PG mainly consists of SO3, CaO with low contents of SiO2, Fe2O3, and P2O5 as well as traces of Na2O, K2O, TiO2, F and 20.8% ignition loss (L.O.I.). It has traces from U and Th (measured by Arsenazo III method) as well as some trace elements (TE) such as Cr, Co, Cu, Cd, Zn, Zr, Pb, Rb, Ba, Sn, and Sr (measured using XRF) in addition to radionuclides such as 226Ra, 210Pb, 238U and 40K. The chemical analysis of PG is seen in Table 1.

Pretreatment of the PG

After dryness and grinding of PG, the bulk sample was carefully quartered into different homogenous smaller samples for chemical and radiometric analysis as well as work’s experiments. One kg of the bulk PG was fractionated into six homogeneous fractions with different particle sizes ranging from 400 to 44 μm to show the effect of particle size on the distribution of radionuclides in these samples. The portions were prepared for the radiometric measurements and the results were shown in Table 2.

The results indicate that most activity levels of 226Ra, 210Pb, 238U and 40K are enriched in the fines particle sizes of PG comparable to that found in the bulk of PG [21]. The distribution of radionuclides content into the different portions was determined in which about 45.4, 53.3, 47, 27.8% of total 226Ra, 210Pb, 238U and 40K respectively were incorporated into coarse portion (<125–400 μm). On the other hand, about 54.6, 46.7, 53, 72.2% of total 226Ra, 210Pb, 238U and 40K respectively were captured into the fine portion (88–44 μm). The distribution of radionuclides decreases with particle size greater than 88 μm. Therefore, for the preparation of PG samples to undergo leaching process, the particle size of PG should be 63 μm (because the radionuclides were concentrated in this size). It is clear that, the fractionation process can be considered as a physical separation of the most interested radionuclides (226Ra, 210Pb, 238U and 40K) in the PG.

The results for distribution of radioactive nuclides under fractionation of PG into fine size are considered as positive results in comparison with those reported by Al-Masri et al. [9], Attallah [21], Bolivar et al. [22] and Reguigui [23] for characterization of radioactive materials in PG waste.

Analytical procedure

The principle for leaching process is that the active agents present in a solid matter are extracted and dissolved in a liquid (usually, but not always a solvent), either in nature or through an industrial process. In general, leaching is the process in which inorganic, organic contaminants or radionuclides are released from the solid phase into the water phase under the influence of mineral dissolution [24–27]. The removal of radionuclides from PG by leaching is essentially important in many industries. The amount of the removed radionuclides depends on many factors such as type of leaching materials and conditions of the process.

In different 250 mL measuring beakers, a known amount of PG (100 g) was taken, with the addition of known volume of diluent at room temperature and mixed for a known time. Other processes were performed by using suitable organic extractants in the desired diluent at the same standard conditions. The factors affect the desired leaching materials (such as contact time, concentration of solvent, liquid: solid ratio, as well as temperature) were optimized.

Total rare earth elements (∑REE) were determined by Arsenazo-III method [13]. In weakly acidic solution, the reagent was violet, whereas their complex with the rare earth elements was green. To the acidic sample solution (pH ≈ 1) 1 mL of 1% ascorbic acid solution was added. After few minutes, 1 mL of the format buffer and 2 mL of arsenazo-III solution were added. The solution was diluted with water to ≈20 mL and the pH was adjusted to ≈2.6. The solution was transferred and diluted with distilled water in 25 mL standard flask. The absorbance was measured at 650 nm against reagent blank solution.

For the analysis of the radionuclides, an accurate weight of 50 g of the sample was initially counted (C o) before leaching. After each leaching process, the solution was separated by centrifugation from the solid. The produced solid residue was dried and radiometrically counted (Cf) again for 226Ra, 210Pb, 238U and 40K.

The removal efficiency (E) of radionuclides and ∑REE can be calculated as follow:

where, C o is the initial radionuclides count (or ∑REE concentration) of the received PG waste and C f is the final radionuclides count (or ∑REE concentration) of the treated PG. The removal efficiency (E) was expressed as leaching percent (%) of waste materials.

Results and discussion

Effect of leaching materials

A series of experiments were carried out using different types of organic solvents. In one experiment, no organic extractant was added to show the effect of diluent type. In the other experiments suitable organic extractants were dissolved in the desired diluent. Under certain conditions of time, temperature, and concentration of reagents, the processes were performed and the results were summarized as follow:

Type of the diluent

The effect of type of diluent was studied by using kerosene, toluene, benzene and n-hexane in leaching of PG. The process was carried out on 100 g PG at: temperature = 25 °C; reaction time = 1 h; and diluent: solid ratio = 1:1. The results are plotted in Fig. 2.

By the addition of n-hexane, benzene, toluene, or kerosene, the removal efficiency (E) % for 226Ra increases gradually to reach 15.7, 20.8, 25.4, or 30.1 respectively. In case of 210Pb, the removal efficiency increases to 13.1, 14, 19.1, or 34.7 by n-hexane, toluene, benzene or kerosene respectively. On the other hand, the uptake of 40K decreases with benzene, kerosene, toluene, or n-hexane with values of 46.2, 42.4, 41.6 or 28.4 respectively. For the removal of 238U, the E% reaches higher value by the addition of kerosene then decreases slightly in case of benzene, toluene, or n-hexane corresponding to 24.3, 22.4, 16.8, and 11.3 respectively. It is clear that, the E% for ∑REE increases from 13% by n-hexane to reach 30% with kerosene.

From the results, it is clear that, kerosene is a more suitable diluent in removal of radionuclides and ∑REE from PG.

Type of the organic extractant

A series of experiments were performed to investigate the effect of different solvents on the removal efficiency of radionuclides and ∑REE from PG. The best solvent was optimized in term of its costs, and ability for radionuclides removal in a good quality. Different types of organic extractants, such as TBP, TOPO, TPPO and DEHPA, dissolved in kerosene were experimented. Using 0.1 M from each solvent, the processes were carried out at: room temperature (25 °C); contact time = 1 h; liquid: solid ratio = 1. The results were graphically presented in Fig. 3.

The results show that, the highest E% values were obtained by using TBP and TOPO. By the addition of TBP, about 42.2, 51.3, 38.7, 47.3 and 46% of 226Ra, 210Pb, 238U, 40K and ∑REE were removed. In case of TOPO, the removal efficiency (E) % of 226Ra, 210Pb, 238U, 40K and ∑REE became 49.9, 38.2, 33.6, 53.8 and 38% respectively. The difference in E% for 226Ra between TBP and TOPO is 7.7%. The effectiveness of the extraction of radium can be further increased by using a more electronegative donor ligand than TBP and a less polar solvent. These results are in agreement with those reported by Sebesta and Havlik [12].

It can be concluded that, the dilution of organic extractant in the suitable diluent such as kerosene has a good effect on the E% of the radionuclides and ΣREE. The type of organic extract and its ability to dilute in kerosene affect the E% to be in the following order:

-

TOPO > TBP > TPPO > DEHPA for 226Ra

-

TBP > TOPO > DEHPA > TPPO for 238U

-

TBP > DEHPA > TPPO > TOPO for 210Pb

-

TOPO > TBP > DEHPA > TPPO for 40K

-

TBP > DEHPA > TOPO > TPPO for ∑REE

Under these conditions the solvent TBP in kerosene is a suitable one due to its low cost and its ability to reduce the radionuclides and ΣREE from PG.

Optimization of leaching with TBP in kerosene

The leaching conditions for treatment of PG using TBP in kerosene are optimized. In this concern, some factors which affect the leachability such as contact time, concentration and volumes of solvent as well as the temperature have been investigated.

Effect of contact time

The effect of reaction time on the leachability of radioactive materials and ΣREE content in the PG was studied. The contact time was ranged between “0.5 to 8″ hours. 100 g of the homogenized (63 μm) PG was agitated at room temperature (25 °C) with 100 mL of 0.1 M of TBP in kerosene (liquid: solid ratio = 1). The results were plotted in Fig. 4.

It is clear that there is a gradual increase in the leachability of radionuclides through the first 2 h, then a very slight increase of E% (less than 1%) for 226Ra and 210Pb at 4 h (as those have higher activity concentration than 238U and 40K) followed by an appreciable decrease up to 8 h. In general, for leaching process, the extracted solid matter must be prepared in the way that the extracted substance can be solved (by the solvent) in short time; this was achieved by grinding the PG to a fine particle size. After grinding, the capillary ways in PG become short so that only a short distance has to be overcome by diffusion and a direct contact of solvent and extracted substance becomes possible in an appreciable time [26–28]. At time of 2 h, E% for 226Ra, 210Pb, 238U, 40K, and ΣREE equals 48.3, 55.7, 40.9, 53.1 and 49 respectively. After this time the particles of PG were saturated with solvent and exceed the fine size. Therefore, agitation time of 2 h was chosen as a sufficient contact time for leaching of PG under using TBP in kerosene.

Effect of TBP concentration

Different concentrations of TBP from 0.05 to 1 M were investigated to show the effect of TBP concentration on the E% of radionuclides and ΣREE. The mixture was agitated for 2 h at room temperature (25 °C) with an equal ratio of organic extractant and PG (L: S = 1:1), and the results were diagrammatically shown in Fig. 5.

The concentration of organic extractant (TBP) in kerosene considered as an influencing factor on leaching of PG. The removal efficiency of radionuclides and ΣREE from PG increases with the concentration to reach maximum value at 0.5 M, then there is an appreciable decrease in E% after this value. The increase in the concentration after 0.5 M leads to decrease the dilution of TBP in kerosene which decreases its ability to leach the radionuclides [24, 25]. Therefore, the concentration of 0.5 M was taken to be a sufficient for leaching of PG. Under this concentration the E% for 226Ra, 210Pb, 238U, 40K, and ΣREE were 61.1, 68.4, 55, 64.7 and 61 respectively.

Effect of liquid/solid ratio

About 100 g of PG were agitated for 2 h with different volumes of (0.5 M) TBP in kerosene under room temperature (25 °C). The volumes of TBP solution range from 50 to 300 mL to 100 g of PG samples which corresponding to 0.5:1 up to 3:1 liquid: solid ratio. The values of removal efficiency of radionuclides and ΣREE were shown in Fig. 6.

The data show that there is a general increase in the E% of 226Ra, 210Pb, 238U, 40K, and ΣREE till liquid: solid ratio = 1. After this ratio the effect of L: S on the leaching process was reversible, i.e. by increasing liquid: solid ratio gradually, the leachability decreases. This behavior indicates that the leaching was affected by the viscosity of the solvent as the low viscosity of the solvent leads to low pressure drop and good mass transfer [25–27], therefore the dose of TBP in kerosene to the amount of PG for leaching of radionuclides and ΣREE must be equal one. It is observed that, equal liquid: solid ratio improves the leaching percent of 226Ra, 210Pb, 238U, 40K, and ΣREE to reach the values of 61.1, 68.4, 55, 64.7, and 61% respectively.

Effect of reaction temperature

To study the effect of temperature on the leaching process, samples of 100 g of the homogenized PG were agitated with 100 mL of (0.5 M) TBP in kerosene for 2 h. The temperature was varied between 25 and 75 °C, and the data were plotted between temperature and the E% for the waste materials in Fig. 7.

The data show that there is a remarkable increase in the E% of radionuclides as well as ΣREE occurs with temperature of 55 °C. In this concern, the leaching process should be performed at high temperatures because with increasing the temperature normally the viscosity of the solvent and the extract decreases. On the other hand the solubility of the extract in the solvent increases [25, 26]. Thus, 55 °C is the suitable temperature to give the best leaching percent of 226Ra, 210Pb, 238U, 40K, and ∑REE which equals 65.6, 72.8, 57.2, 70.4 and 68.5% respectively. As the temperature increases than 55 °C the leaching process does not effected.

Choice of the optimum conditions

From the previous results, the leaching of radionuclides and ΣREE from PG of homogeneous particle size (63 μm) using TBP in kerosene was optimized. Careful selection of the optimum values of these results would be primarily depending on the economic considerations, where the best conditions include:

-

1.

Contact time of 2 h.

-

2,

Concentration of TBP in kerosene: 0.5 M

-

3.

Liquid: solid ratio: 1:1 (TBP in kerosene vol./PG wt.).

-

4.

Temperature of 55 °C (depending on the vapor pressure of the used solvent).

This was indicated by analysis of the obtained organic solution which contains about 310 ± 3.8, 298 ± 5.4, 91.2 ± 3.5, 49.3 ± 1.1 Bq/l, and 270 ppm of 226Ra, 210Pb, 238U, 40K and ΣREE, corresponding to the removal of 65.6, 72.8, 57.2, 70.4 and 68.5% of these materials from the PG, respectively. Radium in the organic phase can be: easily stripped using suitable stripper then introduced in many useful processes.

Successive leaching processes

The PG samples of 63 μm particle size (treated by TBP in kerosene under the optimum experimental conditions of contact time, solvent concentration, liquid to solid ratio, as well as temperature those mentioned above) were subjected to undergo successive leaching process. The results are graphically plotted in Fig. 8.

The results show that, after two successive processes about 5.5% of 226Ra were removed in the second step which corresponds to remove about 71.1% of total 226Ra presents in PG. In the third step there is no removal of 226Ra as the PG was completely saturated with the solvent and so the remained 226Ra can’t be removed. For this purpose the E% of other radionuclides doesn’t increase in the third step. Therefore, in the 2nd step, the E% of 210Pb, 238U, 40K, and ΣREE was 76.4, 62.4, 75.7, and 69.8% respectively.

The results for the removal efficiency of radioactive materials are higher than those obtained by El-Afifi et al. [12]. for leaching of 226Ra and 210Pb from PG wastes using (2.5 M) HNO3 acid solution. The removal efficiency of 226Ra and 210Pb after two successive leaching steps was 51.3 and 45% respectively. Also these values are higher than those reported by El-Gamal [19] for the removal of 226Ra from PG by leaching with ammonium carbonate. The data in this work are considered as good results in comparison with those reported by Pulhani et al. [28]. for leaching of 226Ra and 238U from vertisol soil by ground water in which the probability of leaching was 77 and 40% for 226Ra and 238U respectively. In the work of Haridasan et al. [29]. for leaching of 226Ra from PG waste, the actual removal efficiency of 226Ra through 10 successive leaching steps was found to be 24 and 18% using distilled water and rainwater, respectively. Azouazi et al. [30]. carried out an extensive study on the leaching of PG with different aqueous solutions. The leaching percentages of radionuclides removed were 24.5–29.1 and 23.8–26.4% for 226Ra as well as 210Pb, respectively.

Conclusions

A successful leaching procedure of PG, a by-product from acidulation of the Sebaiya phosphate rock by the wet process phosphoric acid, has been developed in the present work. This was possible through leaching of radionuclides by using suitable organic extractants in applicable diluent. The corresponding relevant factors were studied and the conclusions can be summarized as follows:

Leaching of PG using organic extractants enhances the removal efficiency of the radioactive materials. Using kerosene as a diluent the E% was 30.1, 34.7, 24.3, 42.4 and 30 for 226Ra, 210Pb, 238U, 40K, and ∑REE respectively. By the addition of TBP the E% becomes 42.2, 51.3, 38.7, 47.3 and 46 respectively.

The best conditions for using TBP in kerosene are; agitation time: 2 h, 0.5 M of TBP, and liquid: solid ratio ≈1:1 at 55 °C. These conditions removed 71.1, 76.4, 62.4, 75.7 and 69.8% of 226Ra, 210Pb, 238U, 40K, and ΣREE from PG waste after two successive steps respectively.

Use of available TBP in kerosene (as a lower expensive source of organic solvent than TOPO) in the reduction of radioactive materials from PG waste is more economic to produce local material that can be used in the preparation of low cost products.

References

López R, Valero A, Nieto J (2007) Changes in mobility of toxic elements during the production of phosphoric acid in the fertilizer industry of Huelva (SW Spain) and environmental impact of phosphogypsum wastes. J Hazard Mater 148:745

Tayibi H, Choura M, Lopez F, Alguacil F, Delgado A (2009) Environmental impact and management of phosphogypsum. J Environ Manag 90:2377

El-Didamony H, Abd-El-Aleem S, Abd-El-Aziz M (2003) Untreated phosphogypsum as a set retarder for slag cement production. Ind Ceram 23:19

Lokshin E, Vershkova Y, Vershkov A, Tareeva O (2002) Leaching of lanthanides from phospho-hemihydrate with nitric acid. Russ J Appl Chem 75:1753

Rutherford P, Dudas M, Samek R (1994) Environmental impacts of phosphogypsum. Sci Tot Environ J 149:1

Stoulos S, Manolopoulou M, Papastefanou C (2004) Measurement of radon emanation factor from granular samples: effects of additives in cement. J Appl Radiat Isot 60:49

Misdaq M, Amghar A (2005) Radon and thoron emanation from various marble materials: impact on the workers. Radiat Meas 39:421

Villa M, Moreno H, Manjón G (2005) Determination of 226Ra and 224Ra activity concentration by liquid scintillation counting in sediments samples. Radiat Meas 39:543

Al-Masri M, Al-Bich F (2002) Polonium-210 distribution in Syrian phosphogypsum. J Radioanal Nucl Chem 251:431

Sebesta F, Havlik B (1975) Synergistic extraction of radium using 2-thenoyl-trifluoroactone and tributyl-phosphate or trioctyl-phosphine oxide. J Radioanal Nucl Chem 24:337

Ghose K, Sebesta F, Stary J (1975) Synergetic extraction of radium and barium using 1-phenyl-3-methyl-4-benzoylpyrazol-5-one and trioctyl phosphine oxide. J Radioanal Nucl Chem 24:345

El-Afifi E, Attallah M, Hilal M, El-Reefy S (2010) Treatment of TENORM waste: phosphogypsum produced in fertilizer industry. J Radioact 52:441

Marczenko Z (1986) Spectrophotometric determination of elements. Wiley, New York

Shapiro L and Brannock W (1975) Rapid analysis of silicates, carbonates and phosphates rocks. US Geological Survey Bulletin, Washington, p 1144-A.

Strachnov V, Valkovic V, Zeisler R, Dekner R (1991) Report on the intercomparison run IAEA-312: 226Ra, Th and U in soil. International Atomic Energy Agency (IAEA), Vienna

Strachnov V, Valkovic V, Zeisler R, Dekner R (1991) Report on the intercomparison run IAEA-313: 226Ra, Th and U in stream sediment. IAEA, Vienna

Strachnov V, Valkovic V, Zeisler R, Dekner R (1991) Report on the intercomparison run IAEA-314: 226Ra, Th and U in stream sediment. IAEA, Vienna

Jackson M (2009). Assessment of soil capping for phosphogypsum stack reclamation at fort Saskatchewan. M.Sc. Thesis, University of Alberta, Alberta

El-Gamal E (2007). Studies on the treatment of solid wastes produced during purification of phosphoric acid at phosphoric acid purification pilot plant in Egyptian Nuclear Materials Authority. M.Sc. Thesis, University of Al-Azhar, Cairo

Ramachandran V, Paroli R, Beaudoin J, Delgado A (2002) Handbook of thermal analysis of construction materials. Noyes Publications, New York

Attallah M (2006) Chemical studies on some radionuclides in industrial wastes. M.Sc. Thesis, University of Banha, Banha

Bolivar J, Garía R, León G (1996) On the fractionation of natural radioactivity in the production of phosphoric acid by the wet acid method. J Radioanal Nucl Chem 214:77

Reguigui N (2005) Radionuclide levels and temporal variation in phosphogypsum. J Radioanal Nucl Chem 264:719

Savoval M, Bart H, Seikova I (2005) Enhancement of mass transfer in solid-liquid extraction by pulsed electric field. J Univ Chem Technol Metall 40:329

Perry R, Green D (1988) Perry’s Chemical Engineers’ handbook, 6th edn. McGraw-Hill, New York

Chopey N (2004) Handbook of chemical engineering calculations, 3rd edn. McGraw-Hill, New York

Simpson N (2000) Solid-phase extraction: principles, techniques, and applications. Varian Associates, Inc., Harbor City

Pulhani V, Dafauti S, Hegde A (2007) Leaching of uranium, radium and thorium from vertisol soil by ground water. J Radioanal Nucl Chem 274:341

Haridasan P, Maniyan C, Pillai P, Khan A (2002) Dissolution characteristics of 226Ra from phosphogypsum. J Environ Radioact 62:287

Azouazi M, Ouahidi Y, Fakhi S, Andres Y, Abbe J, Benmansor M (2001) Natural radioactivity in phosphates, phosphogypsum and natural waters in Morocco. J Environ Radioact 54:231

Acknowledgments

The authors wish to thank the Abu-Zaabal Company for fertilizers and Chemicals for providing with the PG samples. The authors also thank the collaboration from Egyptian Nuclear Materials Authority and Atomic Energy Authority.

Open Access

This article is distributed under the terms of the Creative Commons Attribution Noncommercial License which permits any noncommercial use, distribution, and reproduction in any medium, provided the original author(s) and source are credited.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This is an open access article distributed under the terms of the Creative Commons Attribution Noncommercial License (https://creativecommons.org/licenses/by-nc/2.0), which permits any noncommercial use, distribution, and reproduction in any medium, provided the original author(s) and source are credited.

About this article

Cite this article

El-Didamony, H., Ali, M.M., Awwad, N.S. et al. Treatment of phosphogypsum waste using suitable organic extractants. J Radioanal Nucl Chem 291, 907–914 (2012). https://doi.org/10.1007/s10967-011-1547-3

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10967-011-1547-3