Abstract

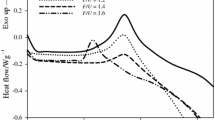

The influence of the preconditioning at different temperatures on the cure kinetics of melamine–urea–formaldehyde resins coated on stone wool was investigated under acidic conditions using differential scanning calorimetry and thermogravimetry. The higher pre-treatment temperature was applied, to which resin-coated stone wool was exposed, the lower was the mass loss during the experiment. Kinetic model parameters were determined in two different manners, with the parameters being independent of preconditioning temperature and dependent on the latter. The apparent orders of reaction were approximately two (all of them being within the range 0.96–2.33), which would imply that cross-linking predominantly proceeds via the bimolecular reaction of either melamine or urea and formaldehyde. Nonetheless, the apparent orders of reaction decreased as a function of preconditioning temperature. The apparent activation energies varied less with preconditioning temperature, assuming values between 64.2 and 78.5 kJ mol−1. The applicability of nth-order reaction kinetic models was consequently validated for two other dynamic thermal regimes.

Similar content being viewed by others

References

Poljanšek I, Likozar B, Krajnc M. Kinetics of hydroxymethyl phenols formation by in-line FTIR spectroscopy. J Appl Polym Sci. 2007;106:878–88.

Higuchi M, Honda T, Tajima S, Sakata I. Behavior and polymeric structures of melamine–urea–formaldehyde resin adhesives. 3. Polymeric structure deduced from the behavior of a cured resin toward acid-hydrolysis. Mokuzai Gakkaishi. 1992;38:374–81.

Scheepers ML, Gelan JM, Carleer RA, Adriaensens PJ, Vanderzande DJ, Kip BJ, Brandts PM. Investigation of melamine–formaldehyde cure by fourier-transform raman-spectroscopy. Vib Spectrosc. 1993;6:55–69.

Jones FN, Chu GB, Samaraweera U. Recent studies of self-condensation and co-condensation of melamine–formaldehyde resins—cure at low-temperatures. Prog Org Coat. 1994;24:189–208.

Braun D, Unvericht R. Model investigation of the co-condensation of melamine and phenol components in MPF thermoset molding materials. Angew Makromol Chem. 1995;226:183–95.

Kim S, Kim HJ, Kim HS, Lee YK, Yang HS. Thermal analysis study of viscoelastic properties and activation energy of melamine-modified urea–formaldehyde resins. J Adhes Sci Technol. 2006;20:803–16.

Cai XL, Riedl B, Wan H, Zhang SY, Wang XM. A study on the curing and viscoelastic characteristics of melamine–urea–formaldehyde resin in the presence of aluminium silicate nanoclays. Compos A. 2010;41:604–11.

Kissinger HE. Reaction kinetics in differential thermal analysis. Anal Chem. 1957;29:1702–6.

Siimer K, Christjanson P, Kaljuvee T, Pehk T, Saks I. Thermal behaviour of hydroxymethyl compounds as models for adhesive resins. J Therm Anal Calorim. 2009;97:459–66.

Jiang JX, Yang YL, Li C, Li JZ. Effect of three boron flame retardants on thermal curing behavior of urea formaldehyde resin. J Therm Anal Calorim. 2011;105:223–8.

Lu X, Pizzi A. Curing conditions effects on the characteristics of thermosetting adhesives-bonded wood joints part 2: hot postcuring improvement of UF particleboards and its temperature forecasting model. Holz Roh Werkstoff. 1998;56:393–401.

Carvalho Luisa MH, Costa Mario Rui PFN, Costa Carlos AV. A very simple empirical kinetic model of the acid-catalyzed cure of urea–formaldehyde resins. J Appl Polym Sci. 2006;102:5977–87.

Vazquez G, Lopez-Suevos F, Gonzalez-Alvarez J, Antorrena G. Curing process of phenol–urea–formaldehyde–tannin (PUFT) adhesives—kinetic studies by DSC and DMA. J Therm Anal Calorim. 2005;82:143–9.

He GB, Riedl B. Phenol–urea–formaldehyde cocondensed resol resins: their synthesis, curing kinetics, and network properties. J Polym Sci Pol Phys. 2003;41:1929–38.

Ghaemy M, Sarrafi Y, Karimi M. Curing kinetics of DGEBA/UF resin system used as laminates in impregnated decorative paper. Iran Polym J. 2010;19:661–8.

Winnik MA, Pinenq P, Kruger C, Zhang JX, Yaneff PV. Crosslinking vs interdiffusion rates in melamine–formaldehyde cured latex coatings: a model for waterborne automotive basecoat. J Coating Technol. 1999;71:47–60.

Kandelbauer A, Wuzella G, Mahendran A, Taudes I, Widsten P. Using isoconversional kinetic analysis of liquid melamine–formaldehyde resin curing to predict laminate surface properties. J Appl Polym Sci. 2009;113:2649–60.

Kandelbauer A, Wuzella G, Mahendran A, Taudes I, Widsten P. Model-free kinetic analysis of melamine–formaldehyde resin cure. Chem Eng Sci. 2009;152:556–65.

Park BD, Jeong HW. Cure kinetics of melamine–formaldehyde resin/clay/cellulose nanocomposites. J Ind Eng Chem. 2010;16:375–9.

Singru RN, Gurnule WB. Thermogravimetric study of 8-hydroxyquinoline 5-sulfonic acid–melamine-formaldehyde terpolymer resins-II. J Therm Anal Calorim. 2010;100:1027–36.

Kohl WS, Frei J, Trethewey BR. Characterization of the cure process in melamine–formaldehyde laminating resins using high-pressure differential scanning calorimetry. Tappi J. 1996;79:199–205.

Friedman HL. Kinetics of thermal degradation of char-forming plastics from thermogravimetry. Application to a phenolic plastic. J Polym Sci Pol Sym. 1964;6:183–95.

Flynn JH, Wall LA. General treatment of the thermogravimetry of polymers. J Res NBS. 1966;70A:487–523.

Ozawa TA. New method of analyzing thermogravimetric data. B Chem Soc Jpn. 1965;38:1881–6.

Acknowledgements

The provision of financial support for the conduct of the research and preparation of the article by Slovenian Research Agency (Programs P2-0152, P1-0134 and P2-0145) is acknowledged.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Likozar, B., Korošec, R.C., Poljanšek, I. et al. Curing kinetics study of melamine–urea–formaldehyde resin. J Therm Anal Calorim 109, 1413–1422 (2012). https://doi.org/10.1007/s10973-011-1883-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-011-1883-0