Abstract

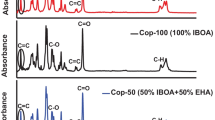

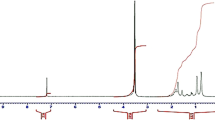

Reversible addition-fragmentation chain transfer polymerization at 70 °C in N,N-dimethylformamide was used to prepare poly(N-isopropylacrylamide-co-N,N-dimethylacrylamide) copolymers in various compositions to afford well-defined polymers with pre-determined molecular weight, narrow molecular weight distribution, and precise chain end structure. The copolymer compositions were determined by 1H NMR spectroscopy. The reactivity ratios of N-isopropylacrylamide (NIPAM) and N,N-dimethylacrylamide (DMA) were calculated as r NIPAM = 0.838 and r DMA = 1.105, respectively, by the extended Kelen–Tüdös method at high conversions. The lower critical solution temperature of PNIPAM can be altered by changing the DMA content in the copolymer chain. Differential scanning calorimetry and thermogravimetric analysis at different heating rates were carried out on these copolymers to understand the nature of thermal degradation and to determine its kinetics. Different kinetic models were applied to estimate various parameters like the activation energy, the order, and the frequency factor. These studies are important to understand the solid state polymer degradation of N-alkyl substituted polymers, which show great potential in the preparation of miscible polymer blends due to their ability to interact through hydrogen bonding.

Similar content being viewed by others

References

Schild HG. Poly(N-isopropylacrylamide): experiment, theory and application. Prog Polym Sci. 1992;17:163–249.

Yin X, Hoffman AS, Stayton PS. Poly(N-isopropylacrylamide-co-propylacrylic acid) copolymers that respond sharply to temperature and pH. Biomacromolecules. 2006;7:1381–5.

Lynch I, Blute IA, Zhmud B, Macartain P, Tosetto M, Allen LT, Byrne HJ, Farrell GF, Keenan AK, Gallagher WM, Dawson KA. Correlation of the adhesive properties of cells to N-isopropylacrylamide/N-tert-butylacrylamide copolymer surfaces with changes in surface structure using contact angle measurements, molecular simulations, and Raman spectroscopy. Chem Mater. 2005;17:3889–98.

Schmaljohann D. Thermo- and pH-responsive polymers in drug delivery. Adv Drug Deliv Rev. 2006;58:1655–70.

Chilkoti A, Chen G, Patrick S, Hoffman AS. Site-specific conjugation of a temperature-sensitive polymer to a genetically engineered protein. Bioconjugate Chem. 1994;5:504–7.

Okhapkin IM, Makhaeva EE, Khokhlov AR. Water solutions of amphiphilic polymers: nanostructure formation and possibilities for catalysis. Adv Polym Sci. 2006;195:177–210.

Wu G, Li Y, Han M, Liu X. Novel thermo-sensitive membranes prepared by rapid bulk photo-grafting polymerization of N,N-diethylacrylamide onto the microfiltration membranes nylon. J Membr Sci. 2006;283:13–20.

Heskins M, Guillet JE. Solution properties of poly(N-isopropylacrylamide). J Macromol Sci Chem A. 1968;2:1441–55.

Fournier D, Hoogenboom R, Thijs HML, Paulus RM, Schubert US. Tunable pH- and temperature-sensitive copolymer libraries by reversible addition-fragmentation chain transfer copolymerizations of methacrylates. Macromolecules. 2007;40:915–20.

Cao Z, Liu W, Gao P, Yao K, Li H, Wang G. Toward an understanding of thermoresponsive transition behavior of hydrophobically modified N-isopropylacrylamide copolymer solution. Polymer. 2005;46:5268–77.

Garbern JC, Hoffman AS, Stayton PS. Injectable pH- and temperature-responsive poly(N-isopropylacrylamide-co-propylacrylic acid) copolymers for delivery of angiogenic growth factors. Biomacromolecules. 2010;11:1833–9.

Schild HG, Tirrell DA. Microheterogeneous solutions of amphiphilic copolymers of N-isopropylacrylamide. An investigation via fluorescence methods. Langmuir. 1991;7:1319–24.

Ringsdorf H, Venzmer J, Winnik FM. Fluorescence studies of hydrophobically modified poly(N-isopropylacrylamides). Macromolecules. 1991;24:1678–86.

Kotsuchibashi Y, Ebara M, Yamamoto K, Aoyagi T. Tunable stimuli-responsive self-assembly system that forms and stabilizes nanoparticles by simple mixing and heating/cooling of selected block copolymers. Polym Chem. 2011;2:1362–7.

Maeda Y, Yamabe M. A unique phase behavior of random copolymer of N-isopropylacrylamide and N-diethylacrylamide in water. Polymer. 2009;50:519–23.

Ashbaugh HS, Paulaitis ME. Monomer hydrophobicity as a mechanism for the LCST behavior of poly(ethylene oxide) in water. Ind Eng Chem Res. 2006;45:5531–7.

Mori H, Iwaya H, Nagai A, Endo T. Controlled synthesis of thermoresponsive polymers derived from l-proline via RAFT polymerization. Chem Commun. 2005;4872–4874.

Teresa MG, Cristina ML, Iglesias E. Study of polymer–polymer complexes and blends of poly(N-isopropylacrylamide) with poly(carboxylic acid): 1. Poly(acrylic acid) and poly(methacrylic acid). Polymer. 1997;38:5091–6.

Saeed A, Georget DMR, Mayes AGJ. Solid-state thermal stability and degradation of a family of poly(N-isopropylacrylamide-co-hydroxymethylacrylamide) copolymers. Polym Sci Part A. 2010;48:5848–55.

Miller A. Field testing two instruments for remotely sensing water quality in the Tennessee Valley. Environ Sci Technol. 1994;28:16A.

e Silva MESR, Dutra ER, Mano V, Machado JC. Preparation and thermal study of polymers derived from acrylamide. Polym Degrad Stab. 2000;67:491–5.

Shibayama M, Mizutani S, Nomura S. Thermal properties of copolymer gels containing N-isopropylacrylamide. Macromolecules. 1996;29:2019–24.

Barker IC, Cowie JMG, Huckerby TN, Shaw DA, Soutar I, Swanson L. Studies of the “smart” thermoresponsive behavior of copolymers of N-isopropylacrylamide and N. N-dimethylacrylamide in dilute aqueous solution. Macromolecules. 2003;36:7765–70.

Chiefari J, Chong YK, Ercole F, Krstina J, Jeffery J, Le TPT, Mayadunne RTA, Meijs GF, Moad CL, Moad G, Rizzardo E, Thang SH. Living free-radical polymerization by reversible addition-fragmentation chain transfer: the RAFT process. Macromolecules. 1998;31:5559–62.

Cambre JN, Roy D, Gondi SR, Sumerlin BS. Facile strategy to well-defined water-soluble boronic acid (co)polymers. J Am Chem Soc. 2007;129:10348–9.

De P, Gondi SR, Roy D, Sumerlin BS. Boronic acid-terminated polymers: synthesis by RAFT and subsequent supramolecular and dynamic covalent self-assembly. Macromolecules. 2009;42:5614–21.

Tüdős F, Kelen T. Analysis of the linear methods for determining copolymerization reactivity ratios. V. Planning of experiments. J Macromol Sci Chem A. 1981;16:1283–97.

Moad G, Chong YK, Postma A, Rizzardo E, Thang SH. Advances in RAFT polymerization: the synthesis of polymers with defined end-groups. Polymer. 2005;46:8458–68.

Wang XS, Li XG, Yan D. Thermal decomposition kinetics of thermotropic poly(oxybenzoate-co-trimethylene terephthalate). J Appl Polym Sci. 2000;78:2025–36.

Jimenez A, Berenguer V, Lopez J, Sanchez A. Thermal degradation study of poly(vinyl chloride): kinetic analysis of thermogravimetric data. J Appl Polym Sci. 1993;50:1565–73.

Cooney JD, Day M, Wiles DM. Thermal degradation of poly(ethylene terephthalate): a kinetic analysis of thermogravimetric data. J Appl Polym Sci. 1983;28:2887–902.

Friedman HL. Kinetics of thermal degradation of char-forming plastics from thermogravimetry. Application to a phenolic plastic. J Polym Sci; Part C. 1963;6:183–95.

Kissinger HE. Reaction kinetics in differential thermal analysis. Anal Chem. 1957;29:1702–6.

Lai JT, Filla D, Shea R. Functional polymers from novel carboxyl-terminated trithiocarbonates as highly efficient RAFT agents. Macromolecules. 2002;35:6754–6.

Convertine AJ, Lokitz BS, Vasileva Y, Myrick LJ, Scales CW, Lowe AB, McCormick CL. Direct synthesis of thermally responsive DMA/NIPAM diblock and DMA/NIPAM/DMA triblock copolymers via aqueous room temperature RAFT polymerization. Macromolecules. 2006;39:1724–30.

Lai JJ, Nelson K, Nash MA, Hoffman AS, Yager P, Stayton PS. Dynamic bioprocessing and microfluidic transport control with smart magnetic nanoparticles in laminar-flow devices. Lab Chip. 2009;9:1997–2002.

Mori H, Kato I, Matsuyama M, Endo T. RAFT polymerization of acrylamides containing proline and hydroxyproline moiety: controlled synthesis of water-soluble and thermoresponsive polymers. Macromolecules. 2008;41:5604–15.

Mori H, Sutoh K, Endo T. Controlled radical polymerization of an acrylamide containing l-phenylalanine moiety via RAFT. Macromolecules. 2005;38:9055–65.

Feil H, Bae YH, Feijen J, Kim SW. Effect of comonomer hydrophilicity and ionization on the lower critical solution temperature of N-isopropylacrylamide copolymers. Macromolecules. 1993;26:2496–500.

Shinde VS, Girme MR, Pawar VU. Thermoresponsive polystyrene-b-poly(N-isopropyl-acrylamide) copolymers by atom transfer radical polymerization. Indian J Chem. 2011;50A:781–7.

Xie X, Hogen-Esch TE. Anionic synthesis of narrow molecular weight distribution water-soluble poly(N,N-dimethylacrylamide) and poly(N-acryloyl-N′-methylpiperazine). Macromolecules. 1996;29:1746–52.

Fox TG. Influence of diluent and of copolymer composition on the glass temperature of a polymer system. Bull Am Phys Soc. 1956;1:123–8.

Postma A, Davis TP, Li G, Moad G, O’Shea MS. RAFT polymerization with phthalimidomethyl trithiocarbonates or xanthates: on the origin of bimodal molecular weight distributions in living radical polymerization. Macromolecules. 2006;39:5307–18.

Acknowledgements

The authors acknowledge the Indian Institute of Science Education and Research-Kolkata and the Department of Science and Technology (DST), New Delhi [SR/S1/OC-51/2010] for partial financial support of this research. Kamal Bauri acknowledges Council of Scientific and Industrial Research (CSIR), Government of India for his fellowships.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Bauri, K., Roy, S.G., Arora, S. et al. Thermal degradation kinetics of thermoresponsive poly(N-isopropylacrylamide-co-N,N-dimethylacrylamide) copolymers prepared via RAFT polymerization. J Therm Anal Calorim 111, 753–761 (2013). https://doi.org/10.1007/s10973-012-2344-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-012-2344-0