Abstract

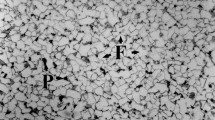

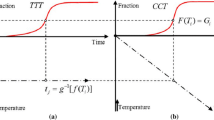

The dendrite coherency point (DCP) temperature refers to the state of a solidifying alloy at which a coherent dendrite network is established during the formation of grains. Several relatively complex methods for detection of the DCP temperature have been developed. There are four main DCP temperature testing approaches: (i) the rheological technique, (ii) thermal analysis of the minimum temperature difference between two cooling curves, (iii) thermal analysis of the second derivative of one cooling curve, and (iv) the thermal diffusivity measurement technique. This paper follows up the proposed thermal analysis of one center cooling curve for the determination of the DCP characteristics such as: temperature, time, instantaneous solidification rate, and fraction solid. The first derivative of the cooling curve is plotted versus the temperature and time and the thermal characteristics of all metallurgical reactions, including the DCP are determined with the same accuracy achieved using the two thermocouple technique developed by Bäckerud et al. [4, 5]. Statistical analysis of the DCP temperature using the one versus two thermocouple techniques shows R 2 equal to 0.99. This research revealed that utilization of dT/dt versus the temperature curve methodology also allows for analysis of the α-Al dendrite nucleation and growth characteristics and consequent determination of the grain size. On-going work on this new methodology for characterization of other solidification events will be presented in subsequent papers.

Similar content being viewed by others

References

Cibula A. The mechanism of grain refinement of sand castings in aluminum alloys. J Inst Metals. 1949/50;76:312.

Mondolfo LF. Aluminum alloys, structure and properties. London: Butterworths; 1979. p. 213–614.

Kierkus WT, Sokolowski JH. Recent advances in cooling curve analysis: a new method of determining the ‘base line’ equation. AFS Trans. 1999;66:161–7.

Bäckerud L, Chai G, Tamminen J. Solidification characteristics of aluminum alloys, foundry alloys, vol. 2. Stockholm: AFS Scanaluminium; 1990.

Bäckerud L, Chalmers B. Some aspects of dendritic growth in binary alloys: study of the aluminum–copper system. Trans Metall Soc AIME. 1969;245:309–18.

Tamminen J. Thermal analysis for investigation of solidification mechanisms in metals and alloys, chemical communications, vol. 2. Stockholm: Stockholm University; 1988.

Jiang H, Kierkus WT, Sokolowski JH. Dendrite coherency point determination using thermal analysis and rheological measurements. In: proceedings of the international conference on thermophysical properties of materials (TPPM 99), Singapore, 17–19 Nov 1999.

Campbell J. Castings. Oxford: Heinemann Ltd.; 1991.

Arnberg L, Dahle A, Paradies C, Syvertsen F. Feeding mechanisms in aluminum foundry alloys. AFS Trans. 1995;115:753–9.

Arnberg L, Chai G, Bäckerud L. Determination of dendritic coherency in solidification melts by rheological measurements. Mater Sci Eng. 1993;A173:101–3.

Chai G. Dendrite coherency during equiaxed solidification in aluminum alloys, chemical communications, vol. 1. Stockholm: Stockholm University; 1994.

Chai G, Bäckerud L, Rolland T, Arnberg L. Dendrite coherency during equiaxed solidification in binary aluminum alloys. Metall Mater Trans A. 1995;26A:965–70.

Veldman N, Dahle A, St. John D. Determination of dendrite coherency point. In: die casting & tooling technology conference, Melbourne, June 1997.

Claxton R. Aluminum alloy coherency. J Metals. 1975;27:14–6.

Djurdjevic M, Kierkus WT, Sokolowski JH. Detection of the dendrite coherency point of Al 3XX series of alloys using a single sensor thermal analysis technique. In: proceedings of 40th annual conference of metallurgists of CIM, Toronto 2001.

Djurdjevic M, Kierkus WT, Liliac RE, Sokolowski JH. Extended analysis of cooling curves. In: proceedings of 41st annual conference of metallurgists of CIM, Montréal, 11–14 Aug 2002.

Zamarripa RC, Ramos-Salas JA, Talamantes-Silva J, Valtierra S, Colas R. Determination of the dendrite coherency point during solidification by means of thermal diffusivity analysis. Metall Mater Trans A. 2007;38A:1875–9.

Easton M, StJohn D. Theoretical advances leading to improvement in commercial grain refinement practices in Al alloys. Mater Forum. 2007;31:57–63.

Golbahar B, Samuel AM, Samuel FH, Doty HW, Valtierra S. Effect of grain refiner-modifier interaction on the microstructure and mechanical properties of A 356.2 alloys. AFS Trans. 2007;07–012(02):1–13.

Dahle L, Lu A. Effects of combined additions of Sr and AlTiB grain refiners in hypoeutectic Al-Si foundry alloys. Mater Sci Eng A. 2006;435–436:288–96.

Acknowledgements

This research is partially funded by AUTO21, a member of the Network of Centres of Excellence program.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Djurdjevic, M.B., Sokolowski, J.H. & Odanovic, Z. Determination of dendrite coherency point characteristics using first derivative curve versus temperature. J Therm Anal Calorim 109, 875–882 (2012). https://doi.org/10.1007/s10973-012-2490-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-012-2490-4