Abstract

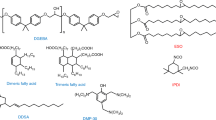

A series of interpenetrating polymer networks (IPNs) based on epoxy (EP) resin and polyurethane (PU) prepolymer derived from soybean oil-based polyols with different mass ratios were synthesized. The structure, thermal properties, damping properties, tensile properties, and morphology of soybean oil-based PU/EP IPNs were characterized by Fourier-transform infrared spectroscopy, differential scanning calorimetry (DSC), dynamic mechanical analysis (DMA), universal test machine, and scanning electron microscopy (SEM). DSC and DMA results show that the glass transition temperature of the soybean oil-based PU/EP IPN decreases with the increase of PU prepolymer contents. Soybean oil-based PU/EP IPNs have better damping properties than that of the pure epoxy resin. The tensile strength and modulus of PU/EP IPNs decrease, while elongation at break increases with the increase of PU prepolymer contents. SEM observations reveal that phase separation appears in PU/EP IPNs with higher PU prepolymer contents.

Similar content being viewed by others

References

Wang YT, Wang CS, Yin HY, Wang LL, Xie HF, Cheng RS. Carboxyl-terminated butadiene–acrylonitrile-toughened epoxy/carboxyl-modified carbon nanotube nanocomposites: thermal and mechanical properties. Express Polym Lett. 2012;6:719–28.

Tripathi G, Srivastava D. Studies on the physico-mechanical and thermal characteristics of blends of DGEBA epoxy, 3,4 epoxy cyclohexylmethyl, 3,4′-epoxycylohexane carboxylate and carboxyl terminated butadiene co-acrylonitrile (CTBN). Mater Sci Eng A. 2008;496:483–93.

Zhang JS, Wang YT, Wang XS, Ding GW, Pan YQ, Xie HF, et al. Effects of amino-functionalized carbon nanotubes on the properties of amine-terminated butadiene-acrylonitrile rubber-toughened epoxy resins. J Appl Polym Sci. 2014;131:6687–93.

Raju T, Ding YM, He YL, Yang L, Paula M, Yang WM, et al. Miscibility, morphology, thermal, and mechanical properties of a DGEBA based epoxy resin toughened with a liquid rubber. Polymer. 2008;49:278–94.

Hodgkin JH, Simon GP, Varley RJ. Thermoplastic toughening of epoxy resins: a critical review. Polym Adv Technol. 1998;9:3–10.

Chern YC, Tseng SM, Hsieh KH. Damping properties of interpenetrating polymer networks of polyurethane-modified epoxy and polyurethanes. J Appl Polym Sci. 1999;74:328–35.

Kostrzewa M, Hausnerova B, Bakar M, Dalka M. Property evaluation and structure analysis of polyurethane/epoxy graft interpenetrating polymer networks. J Appl Polym Sci. 2011;122:1722–30.

Chen CH, Chen MH. Synthesis, thermal properties, and morphology of blocked polyurethane/epoxy full-interpenetrating polymer network. J Appl Polym Sci. 2006;100:323–8.

Lin SP, Han JL, Yeh JT, Chang FC, Hsieh KH. Composites of UHMWPE fiber reinforced PU/epoxy grafted interpenetrating polymer networks. Eur Polym J. 2007;43:996–1008.

Raymond MP, Bui VT. Epoxy/castor oil graft interpenetrating polymer networks. J Appl Polym Sci. 1998;70:1649–59.

Cristea M, Ibanescu S, Cascaval CN, Rosu D. Dynamic mechanical analysis of polyurethane-epoxy interpenetrating polymer networks. High Perform Polym. 2009;21:608–23.

Karak N. Vegetable oil-based polymers: properties, processing and applications. Cambridge: Woodhead Publishing Limited; 2012.

Xia Y, Larock RC. Vegetable oil-based polymeric materials: synthesis, properties, and applications. Green Chem. 2010;12:1893–909.

Dai HH, Yang LT, Lin B, Wang CS, Shi G. Synthesis and characterization of the different soy-based polyols by ring opening of epoxidized soybean oil with methanol, 1,2-ethanediol and 1,2-propanediol. J Am Oil Chem Soc. 2009;86:261–7.

Santos JCO, Santos IMG, Conceiçăo MM, Porto SL, Trindade MFS, Souza AG, et al. Thermoanalytical, kinetic and rheological parameters of commercial edible vegetable oils. J Therm Anal Calorim. 2004;75:419–28.

Dweck J, Sampaio CMS. Analysis of the thermal decomposition of commercial vegetable oils in air by simultaneous TG/DTA. J Therm Anal Calorim. 2004;75:385–91.

Biermann U, Friedt W, Lang S, Luhs W, Machmuller G, Metzger JO, et al. New syntheses with oils and fats as renewable raw materials for the chemical industry. Angew Chem Int Ed Engl. 2000;39:2206–24.

Yang L, Dai H, Yi A, Lin B, Li G. Structure and properties of partially epoxidized soybean oil. J Therm Anal Calorim. 2008;93:875–9.

Lin B, Yang L, Dai H, Hou, Zhang L. Thermal analysis of soybean oil based polyols. J Therm Anal Calorim. 2009;95:977–83.

Wang CS, Yang LT, Ni BL, Shi G. Polyurethane networks from different soy-based polyols by the ring opening of epoxidized soybean oil with methanol, glycol, and 1, 2-propanediol. J Appl Polym Sci. 2009;114:125–31.

Ni BL, Yang LT, Wang CS, Wang LY, Finlow DE. Synthesis and thermal properties of soybean oil-based waterborne polyurethane coatings. J Therm Anal Calorim. 2010;100:239–46.

Wang CS, Chen XY, Chen JQ, Liu CG, Xie HF, Cheng RS. Synthesis and characterization of novel polyurethane acrylates based on soy polyols. J Appl Polym Sci. 2011;122:2449–55.

Wang CS, Wang YT, Liu WJ, Yin HY, Yuan ZR, Wang QJ, et al. Natural fibrous nanoclay reinforced soy polyol-based polyurethane. Mater Lett. 2012;78:85–7.

Wang CS, Chen XY, Xie HF, Cheng RS. Effects of carbon nanotube diameter and functionality on the properties of soy polyol-based polyurethane. Composites A. 2011;41:1620–6.

Wang CS, Ding L, Wu QS, Liu F, Wei J, Lu R, et al. Soy polyol-based polyurethane modified by raw and silylated palygorskite. Ind Crop Prod. 2014;57:29–34.

Chen SB, Wang QH, Wang TM. Damping, thermal, and mechanical properties of carbon nanotubes modified castor oil-based polyurethane/epoxy interpenetrating polymer network composites. Mater Des. 2012;38:47–52.

Chen SB, Wang QH, Wang TM. Dynamic mechanical properties of polysiloxane-modified, castor oil-based polyurethane/epoxy interpenetrating polymer network composites. High Perform Polym. 2011;23:345–51.

Chen SB, Wang QH, Wang TM. Dynamic mechanical properties of castor oil-based polyurethane/epoxy graft interpenetrating polymer network composites. J Appl Polym Sci. 2010;118:1144–51.

Adhvaryu A, Erhan SZ. Epoxidized soybean oil as a potential source of high-temperature lubricants. Ind Crop Prod. 2002;15:247–54.

Lei ZQ, Yang QL, Wu S, Song XL. Reinforcement of polyurethane/epoxy interpenetrating network nanocomposites with an organically modified palygorskite. J Appl Polym Sci. 2009;111:3150–62.

Jia Q, Zheng M, Chen H, Shen R. Morphologies and properties of polyurethane/epoxy resin interpenetrating network nanocomposites modified with organoclay. Mater Lett. 2006;60:1306–9.

Han JL, Tseng SM, Mai JH, Hsieh KH. Polyurethane-crosslinked epoxy resins. II. Compatibility and morphology. Die Angew Makromol Chem. 1991;184:89–97.

Li C, Xu SA, Xiao FY, Wu CF. Dynamic mechanical properties of chlorinated butyl rubber blends. Eur Polym J. 2006;42:2507–14.

Henna PH, Larock RC. Rubbery thermosets by ring-opening metathesis polymerization of a functionalized castor oil and cyclooctene. Macromol Mater Eng. 2007;292:1201–9.

Andjelkovic DD, Lu YS, Kessler MR, Larock RC. Novel rubbers from the cationic copolymerization of soybean oils and dicyclopentadiene, 2-mechanical and damping properties. Macromol Mater Eng. 2009;294:472–83.

Yin HY, Jin H, Wang CS, Sun YF, Yuan ZR, Xie HF, et al. Thermal, damping and mechanical properties of thermosetting epoxy modified asphalts. J Therm Anal Calorim. 2014;115:1073–80.

Li FK, Larock RC. New soybean oil–styrene–divinylbenzene thermosetting copolymers-IV. Good damping properties. Polym Adv Technol. 2002;13:436–49.

Qin CL, Cai WM, Cai J, Tang DY, Zhang JS, Qin M. Damping properties and morphology of polyurethane/vinyl ester resin interpenetrating polymer network. Mater Chem Phys. 2004;85:402–9.

Yu WW, Zhagn DZ, Du M, Zheng Q. Role of graded length side chains up to 18 carbons in length on the damping behavior of polyurethane/epoxy interpenetrating polymer networks. Eur Polym J. 2013;49:1731–41.

Wang C, Jia JR. Damping and mechanical properties of polyol cross-linked polyurethane/epoxy interpenetrating polymer networks. High Perform Polym. 2014;26:240–4.

Chen CH, Sun YY. Mechanical properties of blocked polyurethane/epoxy interpenetrating polymer networks. J Appl Polym Sci. 2006;101:1826–32.

Zhou WY, Zuo J. Mechanical, thermal and electrical properties of epoxy modified with a reactive hydroxyl-terminated polystyrene–butadiene liquid rubber. J Reinf Plast Compos. 2013;32:1359–69.

Tan JH, Wang XP, Tai JJ, Luo YX, Jia DM. Novel blends of acrylonitrile butadiene rubber and polyurethane–silica hybrid networks. Express Polym Lett. 2012;6:588–600.

Dadfar MR, Ghadami F. Effect of rubber modification on fracture toughness properties of glass reinforced hot cured epoxy composites. Mater Des. 2013;47:16–20.

Kim DS, Kin SC. Rubber modified epoxy resin. II: phase separation behavior. Polym Eng Sci. 1994;34:598–604.

Acknowledgements

The authors are grateful to the financial support from Opening Funds of National Engineering Laboratory for Advance Road Materials, Program for Changjiang Scholars and Innovative Research Team in University (PCSIRT) and the Fundamental Research Funds for the Central Universities (20620140066).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Jin, H., Zhang, Y., Wang, C. et al. Thermal, mechanical, and morphological properties of soybean oil-based polyurethane/epoxy resin interpenetrating polymer networks (IPNs). J Therm Anal Calorim 117, 773–781 (2014). https://doi.org/10.1007/s10973-014-3849-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-014-3849-5