Abstract

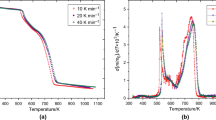

The thermal decomposition behavior of the commercial flame-retardant ethylene–propylene–diene monomer (EPDM) rubber was studied employing cone calorimeter and simultaneous thermogravimetry (TG)–differential scanning calorimetry (DSC). Significant influence of the external heat flux on the thermal decomposition behavior of the commercial flame-retardant EPDM rubber was characterized with the measurement of various parameters, including the visual observation, the ignition time, the mass loss, the mass loss rate, the heat release rate and the effective heat of combustion employing cone calorimeter. Three different decomposition regions of the commercial flame-retardant EPDM rubber may be identified according to the applied external heat flux employing cone calorimeter: (1) region 1 (external heat flux ≤35 kW m−2) with well exertion of effectiveness of fire retardants to the EPDM rubber; (2) region 2 (35 kW m−2 < external heat flux ≤ 45 kW m−2) with gradual loss of effectiveness of fire retardants to the EPDM rubber; and (3) region 3 (external heat flux >45 kW m−2) with little effectiveness of fire retardants to the EPDM rubber. Six thermal decomposition stages of the commercial flame-retardant EPDM rubber were noted in both of region 2 and 3. However, merely four thermal decomposition stages were demonstrated in region 1. Similar thermal decomposition behaviors of the commercial flame-retardant EPDM rubber to those of cone calorimeter experiments were examined in the TG–DSC tests, thus validating the cone calorimeter experimental results. The present study may be of practical use in fire safety design of the underground rail transportation systems.

Similar content being viewed by others

References

Peacock RD, Braun E. Fire safety of passenger trains, phase I: material evaluation (cone calorimeter). NISTIR 6132. Gaithersburg: National Institute of Standards and Technology; 1999.

NF F 31-812. Railway rolling stock, rubber floor coverings. Paris: Association Francaise de Normalisation; 1990.

Duggan G. Usage of ISO 5660 data in UK railway standards and fire safety cases. In: A one-day conference on fire hazards, testing, materials and products. Shrewsbury: Rapra Technology; 1997. p. 1–8.

Peacock RD, Bukowski RW, Markos SH. Evaluation of passenger train car materials in the cone calorimeter. Fire Mater. 1999;23(2):53–62.

Peacock RD, Reneke PA, Averill JD, Bukowski R, Klote JH. Fire safety of passenger trains, phase II: application of fire hazard analysis techniques. NISTIR 6525. Gaithersburg: National Institute of Standards and Technology; 2001.

Hong W. The progress and controlling situation of Daegu Subway fire disaster. In: Lee SK, editor. Sixth Asia–Oceania symposium on fire science and technology. Daegu, Korea: International Association for Fire Safety Science; 2004. p. 17–20.

Chiam BH. Numerical simulation of a metro train fire. Master dissertation, University of Canterbury, New Zealand. 2005.

Dowling V, White N, Webb A, Barnett J. When a passenger train burns, how big is the fire? Invited lecture. In: Chow WK, editor. Proceedings of the 7th Asia–Oceania symposium on fire science and technology. Hong Kong, China: International Association for Fire Safety Science; 2007. p. 19–28.

TB/T 3237. Flame retardant technical specification of decorating materials for multiple unit train (in Chinese). Beijing: China Ministry of Railways; 2010.

White N. Fire development in passenger trains. Master dissertation, Victoria University, Australia. 2010.

Schebel K, Meacham BJ, Dembsey NA, Johann M, Tubbs J, Alston J. Fire growth simulation in passenger rail vehicles using a simplified flame spread model for integration with CFD analysis. J Fire Prot Eng. 2012;22(3):197–225.

Lee D, Park W, Jung W, Yang S, Kim H, Hadjishophocleous G, et al. Estimations of heat release rate curve of railcar fire. J Mech Sci Technol. 2013;27(6):1665–70.

Li Y, Ingason H, Lönnermark A. Fire development in different scales of a train carriages. In: Hees P van, editor. 11th International symposium on fire safety science. Christchurch: International Association for Fire Safety Science; 2014.

NFPA-130. Standard for fixed guideway transit and passenger rail systems. Quincy: National Fire Protection Association; 2010.

Roh JS, Ryou HS, Park WH, Jang YJ. CFD simulation and assessment of life safety in a subway train fire. Tunn Undergr Sp Technol. 2009;24(4):447–53.

Cheng M, Chen W. Experimental investigation of the stress stretch behavior of EPDM rubber with loading rate effects. Int J Solids Struct. 2003;40(18):4749–68.

Babrauskas V. Ignition handbook: principles and applications to fire safety engineering, fire investigation, risk management and forensic science. 2nd ed. Issaquah: Fire Science; 2003.

Lyon RE, Quintiere JG. Criteria for piloted ignition of combustible solids. Combust Flame. 2007;151(4):551–9.

Song L, Zhou S, Wu J, Hu Y. Synergistic effects of lanthanum oxide on magnesium hydroxide flame-retarded ethylene propylene diene terpolymer composite. Polym Plast Technol. 2009;48(10):1088–93.

Shen ZQ, Chen L, Lin L, Deng CL, Zhao J, Wang YZ. Synergistic effect of layered nanofillers in intumescent flame-retardant EPDM: montmorillonite versus layered double hydroxides. Ind Eng Chem Res. 2013;52(25):8454–63.

Yen YY, Wang HT, Guo WJ. Synergistic effect of aluminum hydroxide and nanoclay on flame retardancy and mechanical properties of EPDM composites. J Appl Polym Sci. 2013;130(3):2042–8.

ISO 5660-1. Reaction-to-fire tests-heat release, smoke production and mass loss rate-part 1: heat release rate (cone calorimeter method). 2nd ed. Geneva: International Organization for Standardization; 2002.

Tsai KC. Orientation effect on cone calorimeter test results to assess fire hazard of materials. J Hazard Mater. 2009;172(2):763–72.

Kim J, Lee J, Kim S. Estimating the fire behavior of wood flooring using a cone calorimeter. J Therm Anal Calorim. 2012;110(2):677–83.

Xu Q, Majlingova A, Zachar M, Jin C, Jiang Y. Correlation analysis of cone calorimetry test data assessment of the procedure with tests of different polymers. J Therm Anal Calorim. 2012;110(1):65–70.

Ma Y, Wang J, Xu Y, Wang C, Chu F. Preparation and characterization of phenolic foams with eco-friendly halogen-free flame retardant. J Therm Anal Calorim. 2013;114(3):1143–51.

Qu H, Liu C, Wu W, Chen L, Xu J. Using cone calorimeter to study thermal degradation of flexible PVC filled with zinc ferrite and Mg (OH)2. J Therm Anal Calorim. 2014;115(2):1081–7.

An W, Jiang L, Sun J, Liew K. Correlation analysis of sample thickness, heat flux, and cone calorimetry test data of polystyrene foam. J Therm Anal Calorim. 2014:1–10. doi:10.1007/s10973-014-4165-9.

Walton WD, Thomas PH. Estimating temperatures in compartment fires. In: DiNenno PJ, editor. SFPE handbook of fire protection engineering. 3rd ed. Quincy: National Fire Protection Association; 2002. p. 3.171–88.

Schartel B, Hull TR. Development of fire-retarded materials-Interpretation of cone calorimeter data. Fire Mater. 2007;31(5):327–54.

Gao L, Zheng G, Zhou Y, Hu L, Feng G. Thermal performances and fire behaviors of rosin-based rigid polyurethane foam nanocomposites. J Therm Anal Calorim. 2014:1–14. doi:10.1007/s10973-014-4192-6.

Xu Q, Jin C, Jiang Y. Analysis of the relationship between MCC and thermal analysis results in evaluating flammability of EPS foam. J Therm Anal Calorim. 2014;118:687–93.

Luche J, Rogaume T, Richard F, Guillaume E. Characterization of thermal properties and analysis of combustion behavior of PMMA in a cone calorimeter. Fire Saf J. 2011;46(7):451–61.

Luche J, Mathis E, Rogaume T, Richard F, Guillaume E. High-density polyethylene thermal degradation and gaseous compound evolution in a cone calorimeter. Fire Saf J. 2012;54:24–35.

Quang Dao D, Luche J, Richard F, Rogaume T, Bourhy-Weber C, Ruban S. Determination of characteristic parameters for the thermal decomposition of epoxy resin/carbon fibre composites in cone calorimeter. Int J Hydrog Energy. 2013;38(19):8167–78.

Batiot B, Luche J, Rogaume T. Thermal and chemical analysis of flammability and combustibility of fir wood in cone calorimeter coupled to FTIR apparatus. Fire Mater. 2014;38(3):418–31.

Babrauskas V. The cone calorimeter. In: DiNenno PJ, editor. SFPE handbook of fire protection engineering. 3rd ed. Quincy: National Fire Protection Association; 2002. p. 3.63–81.

ISO 17554. Reaction to fire-mass loss measurement. Geneva: International Organization for Standardization; 1998.

ISO 13943. Fire safety-vocabulary. 2nd ed. Geneva: International Organization for Standardization; 2000.

Karlsson B, Quintiere JG. Enclosure fire dynamics. New York: CRC Press; 2000.

Chen R, Lu S, Zhang B, Li C, Lo S. Correlation of rate of gas temperature rise with mass loss rate in a ceiling vented compartment. Chin Sci Bull. 2014;59(33):4559–67.

Babrauskas V, Peacock RD. Heat release rate: the single most important variable in fire hazard. Fire Saf J. 1992;18(3):255–72.

Thornton W. The relation of oxygen to the heat of combustion of organic compounds. Lond Edinb Dublin Philos Mag J Sci. 1917;33(194):196–203.

Janssens ML. Measuring rate of heat release by oxygen consumption. Fire Technol. 1991;27(3):234–49.

Mouritz AP, Gibson A. Fire properties of polymer composite materials. Dordrecht: Springer; 2007.

Wang Y, Zhang J. Thermal stabilities of drops of burning thermoplastics under the UL 94 vertical test conditions. J Hazard Mater. 2013;246:103–9.

Chen X, Jiang Y, Jiao C. Smoke suppression properties of ferrite yellow on flame retardant thermoplastic polyurethane based on ammonium polyphosphate. J Hazard Mater. 2014;266:114–21.

Hu Y, Lei S, You F, Zhong MH. Introduction to fire dynamics (in Chinese). Beijing: Chemical Industry Press; 2007.

Acknowledgements

This work was sponsored by the Research Fund for the Doctoral Program of Higher Education of China (Grant Nos. 20123402110048 and 20123402120018) and National Natural Science Foundation of China (Grant Nos. 51206157 and 51323010). The authors thank associate Prof. Lei Song and Dr. Qilong Tai from University of Science and Technology of China and research assistant Wei Tang from University of Maryland for their help with the discussion.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chen, R., Lu, S., Li, C. et al. Characterization of thermal decomposition behavior of commercial flame-retardant ethylene–propylene–diene monomer (EPDM) rubber. J Therm Anal Calorim 122, 449–461 (2015). https://doi.org/10.1007/s10973-015-4701-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-015-4701-2