Abstract

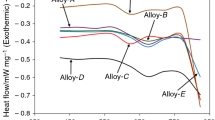

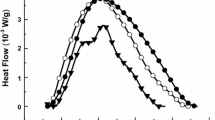

The kinetics of phase precipitation of an AA7075 alloy subjected to retrogression and reaging (RRA) temper were theoretically characterized in each of the stages of that treatment. Calorimetric measurements were used to determine the exothermic reactions promoting the precipitation process of phases coexisting in the temperature range from 200 to 450 °C. Using deconvolution methods, the reactions were separated by means of Weibull transfer functions, and each deconvolved reaction was analyzed by combining isoconversion and linear regression methods. A kinetic analysis was performed through the Sestak–Berggren kinetic function, thus determining each kinetic parameter. The RRA temper in the temperature range studied required at least two reactions to have the minimum experimental–theoretical correlation condition set at R 2 ≥ 0.99, and three reactions to attain a value of R 2 ≥ 0.998. This study concerns deconvolution with three reactions, two, respectively, associated with the precipitation of phases η′ and η; and a third phase containing Cu (S phase). The results permit to predict that the physical mechanism controlling the precipitation process during the stages of homogenization and retrogression is the migration of alloying elements that exploit quenching vacancy oversaturation, whereas the dominant mechanism during aging and reaging is the diffusion of Zn, Mg, and Cu through the matrix.

Similar content being viewed by others

References

Rambabu P, Eswara PN, Kutumbarao VV, Wanhill RJH. Aluminum alloys for aerospace applications. In: Indian Institute of Metals Series—Aerospace Materials and Material Technologies; 2016. p. 29–52.

Mohamed AB, Znaidi A, Baganna M, Nasri R. The study of the hardening precipitates and the kinetic precipitation. In: Its influence on the mechanical behavior of 2024 and 7075 aluminum alloys used in aeronautics. Multiphysics modelling and simulation for systems design and monitoring. 2014; p. 219–228.

Deiasi R, Adler PN. Calorimetric studies of 7000 series aluminum alloys: I. Matrix precipitate characterization of 7075. Metall Trans A. 1977;8A:1177–83.

Papazian JM, Deiasi RJ, Adler PN. A calorimetric study of fatigue induced microstructural changes in aluminum alloy 7050. Metall Trans A. 1980;11A:135–40.

Loyd DJ, Haturvedi MC. A calorimetric study of aluminum alloy AA-7075. J Mater Sci. 1982;17(6):1819–24.

Marlaud T, Deschamps A, Bley F, Lefebvre W, Baroux B. Evolution of precipitate microstructures during the retrogression and re-ageing heat treatment of an Al–Zn–Mg–Cu alloy. Acta Mater. 2010;58:4814–26.

Nicolas M, Deschamps A. Characterization and modeling of precipitate evolution in an Al–Zn–Mg alloy during non-isothermal heat treatments. Acta Mater. 2003;51:6077–94.

Emani SV, Benedyk J, Nash P, Chen D. Double aging and thermomechanical heat treatment of AA7075 aluminum alloy extrusions. J Mater Sci. 2009;44:6384–91.

Chen SY, Chen KH, Dong PX, Ye SP, Huang LP, Yang DJ. Effect of a novel three-step aging on strength, stress corrosion cracking and microstructure of AA7085. J Cent South Univ. 2016;23(8):1858–62.

Cina B, Gan R. Reducing the susceptibility of alloys, particularly aluminum alloys, to stress corrosion cracking the United States patent 3856584 (1974).

Cina B, Ranish B. Aluminum industrial product. Pittsburgh: American Society for Metals; 1974.

Talianker M, Cina B. Retrogression and reaging and the role of dislocations in the stress corrosion of 7000-type aluminum alloys. Metall Mater Trans A. 1989;20A:2087–92.

Es-Said OS, Frazier WE, Lee EW. The effect of retrogression and reaging on the properties of the 7249 aluminum alloy. JOM. 2003;55(1):45–8.

Wu XJ, Raizenne MD, Chen WR, Poon C, Wallace W. Thirty years of retrogression and reaging ICAS 2002. In: Proceedings Toronto-Canada; 2002. p. 1–11.

Baldantoni A. On the microstructural changes during the retrogression and re-aging of 7075 type aluminum alloys. Mater Sci Eng. 1985;72:L5–8.

Viana F, Pinto AMP, Santos HMC, Lopes AB. Retrogression and re-ageing of 7075 aluminum alloy: microstructural characterization. J Mater Process Technol. 1999;92–93:54–9.

Philip J, Sathiyamurthy S. Investigation of the Scc behaviour of 7075 aluminium alloy after two-step aging at 225 °F and 325 °F. IJEI. 2017;6(4):35–41.

Esmailian M, Shakouri M, Mottahedi A, Shabestari SG. Effect of T6 and re-aging heat treatment on mechanical properties of 7055 aluminum alloy. Int J Chem Mol Nucl Mater Metall Eng. 2015;9(11):1303–6.

Jaburek N, Merklein M. Influence of a retrogression and reaging (RRA)-treatment on the mechanical and microstructural characteristics of the aluminum alloy AlZn4, 5Mg1. Prod Eng Res Dev. 2015;9(2):161–6.

Chen YG, Zhong Y, Yin JC, Wang LQ, Liu LN, Yang H, Liu YL. Microstructure and properties of 7075Al alloy fabricated by directly combined of spray forming and continuous extrusion forming under different atomization gas pressures. Acta Metall Sin (Engl Lett). 2016;29(9):804–12.

Su RM, Qu YD, You JH, Li RD. Study on a new retrogression and re-aging treatment of spray formed Al–Zn–Mg–Cu alloy. J Mater Res. 2016;31(5):573–9.

Yildirim M, Özyürek D, Gürü M. The effects of precipitate size on the hardness and wear behaviors of aged 7075 aluminum alloys produced by powder metallurgy route. Arab J Sci Eng. 2016;41(11):4273–81.

Ruppert M, Strebl M, Höppel HW, Göken M. Mechanical properties of ultrafine-grained AlZnMg(Cu)-alloys AA7020 and AA7075 processed by accumulative roll bonding. J Mater Sci. 2015;50(12):4422–9.

Ma S, Sun Y, Wang H, Lü X, Qian M, Ma Y, Zhang C, Liu B. Effect of a minor Sr modifier on the microstructures and mechanical properties of 7075 T6 Al alloys. Metals. 2017;. doi:10.3390/met7010013.

Ryum N. Microstructures in a precipitation-hardened Al–Zn–Mg-Alloy, with particular reference to structures developed during welding. Z Met. 1975;66:338–45.

Li X, Starink MJ. Analysis of precipitation and dissolution in overaged 7xxx aluminum alloys using DSC. Mater Sci Forum. 2000;331–337:1071–6.

Buha J, Lumley RN, Crosky AG. Secondary aging in an aluminum alloy 7050. Mater Sci Eng A. 2008;492:1–10.

Zhao YH, Liao XZ, Jin Z, Valiev RZ, Zhu YT. Microstructures and mechanical properties of ultrafine grained 7075 Al alloy processed by ECAP and their evolutions during annealing. Acta Mater. 2004;52:4589–99.

Naeem HT, Mohammed KS. Retrogression and re-aging of aluminum alloys (AA 7075) containing nickel. Dig J Nanomater Biostruct. 2013;8(4):1621–32.

Sha G, Cerezo A. Early-stage precipitation in Al–Zn–Mg–Cu alloy (7050). Acta Mater. 2004;52(15):4503–16.

Luiggi NJ, Valera M. Kinetic study of phase precipitation of an AA7075 alloy under T6 and T7 Temper (in Spanish; RLMM: Accepted); 2017.

Xingang F, Daming J, Qingchang M, Li Z. The microstructural evolution of an Al–Zn–Mg–Cu alloy during homogenization. Mater Lett. 2006;60:1475–9.

Luiggi NJ. Kinetic analysis of recovery, recrystallization, and phase precipitation in an Al–Fe–Si alloy using JMAEK and Sesták–Berggren models. Metall Mater Trans B. 2015;46(3):1376–99.

Christian JW. The theory of transformation in metals and alloys. 2nd ed. Oxford: Pergamon Press; 1975.

Gallagher PK, editor. Handbook of thermal analysis and calorimetry series. Columbus, Amsterdam: Department of Chemistry, Ohio State University, Elsevier; 1998.

Haines PJ. Editor principles of thermal analysis and calorimetry, Oakland Analytical Services, Farnhurn, Surrey, UK, The Royal Society of Chemistry; 2002.

Vyazovkin S, Burnham AK, Criado JM, Pérez-Maqueda LA, Popescu C, Sbirrazzuoli N. ICTAC Kinetics Committee recommendations for performing kinetic computations on thermal analysis data. Thermochim Acta. 2011;520:1–19.

Gotor FJ, Criado JM, Malek J, Koga N. Kinetic analysis of solid-state reactions: the universality of master plots for analyzing isothermal and nonisothermal experiments. J Phys Chem. 2000;104:10777–82.

Sesták J, Berggren G. Study of the kinetics of the mechanism of solid-state reactions at increasing temperature. Thermochim Acta. 1971;3:1–12.

Šesták J. Science of heat and thermophysical studies: a generalized approach to thermal analysis. Amsterdam: Elsevier; 2005.

Šesták J, Kozmidis-Petrović A, Živković Ž. Crystallization kinetics accountability and the correspondingly developed glass-forming criteria—a personal recollection at the forty years anniversaries. J Min Metall Sect B Metall. 2011;47(2B):229–39.

Starink MJ, Zahra AM. An analysis method for nucleation and growth controlled reactions at a constant heating rate. Thermochim Acta. 1997;292:159.

Starink MJ. β′ and β precipitation in an Al–Mg alloy studied by DSC and TEM. Acta Mater. 1998;46:3381–97.

Malek J. The applicability of Johnson–Mehl–Avrami model in the thermal analysis of the crystallization kinetics of glasses. Thermochim Acta. 1995;267:61–73.

Malek J. Kinetic analysis of crystallization processes in amorphous materials. Thermochim Acta. 2000;355:239–53.

Oppenheim AV, Schafer R. Discrete-time signal processing. Upper Saddle River: Prentice Hall; 1989.

Mendel J, Burrus CS. Maximum-likelihood deconvolution: a journey into model-based signal processing. New York: Springer; 1990.

Peak Fit Manual. http://www.sigmaplot.co.uk/products/peakfit/peakfit-features.php.

Wei F, Zhao ZK, Liu PY, Zhou TT. Research and development of Al–Zn–Mg–Cu–Li alloys. Mater Forum. 2004;28:75–84.

Dobra G, Sava I, Petre M, Popa G, The optimization of the homogenization treatment of AA7075. In: Light metals: the minerals, metals & materials series; 2017. p. 315–326.

Vyazovkin S, Wight CA. Model-free and model-fitting approaches to the kinetic analysis of isothermal and nonisothermal data. Thermochim Acta. 1999;340(341):53–68.

Luiggi NJ. Comments on the analysis of experimental data in nonisothermal kinetics. Metall Mater Trans A. 2003;34A:2679–81.

Ghosh KS, Gao N. Determination of kinetic parameters from calorimetric study. Trans Nonferrous Met Soc China. 2011;21:1199–209.

Ullmaier H, Landolt-Börnstein, editors. Atomic defects in metals, ed., new series group III, vol. 25. Berlin: Springer; 1991.

Fujikawa SI, Takada Y. Interdiffusion between aluminum and Al–Mg alloys. Defect Diffus Forum. 1997;143–147:409–14.

Martina M, Wang Y, Chen LQ, Liu ZK, Wolverton C. First-principles impurities diffusion coefficients. Acta Mater. 2009;57:4102–8.

Balluffi RW. On measurements of self-diffusion rates along dislocations in FCC metals. Phys Stat Solid A. 1970;42:11–34.

Jannot E, Mohles V, Gottstein G, Thijsse B. Atomistic simulation of pipe diffusion in AlCu alloys. Defect Diffus Forum. 2006;249:47–54.

Brown AM, Ashby MF. Correlations for diffusion constants. Acta Metall. 1980;28:1085–101.

Doherty RD, Hughes DA, Humphreys FJ, Jonas JJ, Jensen DJ, Kassner ME, King WE, McNelley TR, McQueen HJ, Rollett AD. Current issues in recrystallization: a review. Mater Sci Eng A. 1997;238:219–74.

Federighi T. The concept of ideal pre-precipitation in supersaturated solid solutions. Le J de Phys et le Radium. 1962;23:795–806.

Ferragut R, Somoza A, Torriani I. Pre-precipitation study in the 7012 Al–Zn–Mg–Cu alloy by electrical resistivity. Mater Sci Eng. 2002;A334:1–5.

Afify N, Gaber AF, Abbady G. Fine-scale precipitates in Al–Mg–Zn alloys after various aging temperatures. Mater Sci Appl. 2011;2:427–34.

Ramanarayanana P, Srinivasan B, Cho K, Clemens BM. Migration energy for impurity diffusion in crystalline solids: a closer look. J Appl Phys. 2004;96(12):7095–107.

Callister WD Jr. Materials science and engineering: an introduction. 2nd ed. New York: Wiley; 1991. p. 105.

Acknowledgements

The authors gratefully acknowledge the support granted by the Office of Academic Planning at the Universidad de Oriente through POA Project PN 5.5/2010, and the revision of the English text by Carlos Mota (Traduce C.A., Cumaná, Venezuela).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Luiggi, N.J., Valera, M.V. Kinetic study of an AA7075 alloy under RRA heat treatment. J Therm Anal Calorim 130, 1885–1902 (2017). https://doi.org/10.1007/s10973-017-6683-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-017-6683-8