Abstract

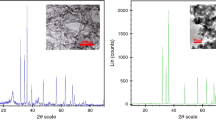

In this study, the rheological behavior and viscosity of a stable nanofluid, which is prepared with the suspension of MCM-41 nanoparticles in SAE40 engine oil as base fluid, would be presented. Two-step method has been used to stabilize the nanoparticles in engine oil. To obtain structural and morphological properties of the synthesized nanoparticles, small-angle X-ray scattering, N2 adsorption/desorption analysis and scanning electron microscopy have been done. Then, viscosity of nanofluids has been measured in temperature range of 25–55 °C, shear rates up to 13,000 s−1 and different concentrations (0 mass%, 0.5 mass%, 1 mass%, 3 mass% and 5 mass% of MCM-41 nanoparticles). For all the samples, the shear stress versus shear rate diagrams showed that SAE40 oil has Newtonian behavior, in which adding mesoporous silica nanoparticles causes non-Newtonian or pseudoplastic behavior. The results declared that viscosity decreases with increasing temperature and increases with an enhancement in concentration. Furthermore, based on experimental results, an accurate correlation has been proposed to predict the viscosity of SAE40/MCM-41 nanolubricants.

Similar content being viewed by others

Abbreviations

- ANOVA:

-

Analysis of variance

- IUPAC:

-

International union of pure and applied chemistry

- MCM:

-

Mobil composition of mater

- R :

-

Regression coefficient

- SAE:

-

Society of automotive engineers

- SAXS:

-

Small-angle X-ray scattering

- SEM:

-

Scanning electron microscopy

- SSA:

-

Specific surface area (m2 g−1)

- ϕ :

-

Mass percentage

- Τ :

-

Shear stress (Pa)

- \(\dot{\gamma }\) :

-

Shear rate (s−1)

- \(\mu_{\text{nf}}\) :

-

Dynamic viscosity of nanofluid (mPa s)

- \(\mu_{\text{bf}}\) :

-

Dynamic viscosity of base fluid (mPa s)

- \(m_{\text{np}}\) :

-

Mass of nanoparticle (g)

- \(m_{\text{bf}}\) :

-

Mass of fluid (g)

References

Rashidi S, Kashefi MH, Hormozi F. Potential applications of inserts in solar thermal energy systems: a review to identify the gaps and frontier challenges. Sol Energy. 2018;171:929–52.

Rashidi S, Karimi N, Mahian O, Esfahani JA. A concise review on the role of nanoparticles upon the productivity of solar desalination systems. J Therm Anal Calori. 2018. https://doi.org/10.1007/s10973-018-7500-8.

Rashidi S, Eskandarian M, Mahian O, Poncet S. Combination of nanofluid and inserts for heat transfer enhancement. J Therm Anal Calorim. 2018. https://doi.org/10.1007/s10973-018-7070-9.

Rashidi S, Mahian O, Languri EM. Applications of nanofluids in condensing and evaporating systems. J Therm Anal Calorim. 2018;131(3):2027–39.

Rashidi S, Akar S, Bovand M, Ellahi R. Volume of fluid model to simulate the nanofluid flow and entropy generation in a single slope solar still. Renew Energy. 2018;115:400–10.

Ijaz N, Zeeshan A, Bhatti M, Ellahi R. Analytical study on liquid–solid particles interaction in the presence of heat and mass transfer through a wavy channel. J Mol Liq. 2018;250:80–7.

Zeeshan A, Shehzad N, Ellahi R. Analysis of activation energy in Couette–Poiseuille flow of nanofluid in the presence of chemical reaction and convective boundary conditions. Results Phys. 2018;8:502–12.

Ellahi R, Zeeshan A, Shehzad N, Alamri SZ. Structural impact of kerosene-Al2O3 nanoliquid on MHD Poiseuille flow with variable thermal conductivity: application of cooling process. J Mol Liq. 2018;264:607–15.

Majeed A, Zeeshan A, Alamri SZ, Ellahi R. Heat transfer analysis in ferromagnetic viscoelastic fluid flow over a stretching sheet with suction. Neural Comput Appl. 2018;30(6):1947–55.

Hassan M, Marin M, Alsharif A, Ellahi R. Convective heat transfer flow of nanofluid in a porous medium over wavy surface. Phys Lett A. 2018;382:274–2753.

Zeeshan A, Ijaz N, Abbas T, Ellahi R. The sustainable characteristic of bio-bi-phase flow of peristaltic transport of MHD Jeffrey fluid in the human body. Sustainability. 2018;10(8):2671.

Akbarzadeh M, Rashidi S, Karimi N, Ellahi R. Convection of heat and thermodynamic irreversibilities in two-phase, turbulent nanofluid flows in solar heaters by corrugated absorber plates. Adv Powder Technol. 2018;29(9):2243–54.

Hussain F, Ellahi R, Zeeshan A. Mathematical models of electro-magnetohydrodynamic multiphase flows synthesis with nano-sized hafnium particles. Appl Sci. 2018;8(2):275.

Shehzad N, Zeeshan A, Ellahi R. Electroosmotic flow of MHD power law Al2O3–PVC nanouid in a horizontal channel: Couette–Poiseuille flow model. Commun Theor Phys. 2018;69(6):655.

Choi SU, Eastman JA. Enhancing thermal conductivity of fluids with nanoparticles. Argonne: Argonne National Lab.; 1995.

Le VNA, Lin JW, editors. Influence of aluminum nanoparticles additives on tribological properties of base oil. Key engineering materials. Zurich: Trans Tech Publ; 2017.

Guo J, Barber GC, Schall DJ, Zou Q, Jacob SB. Tribological properties of ZnO and WS2 nanofluids using different surfactants. Wear. 2017;382:8–14.

Bhaumik S, Pathak S. Effect of nano and micro friction modifier based lubricants on wear behavior between steel–steel contacts. Tribol Ind. 2017;39(1):136–43.

Zin V, Agresti F, Barison S, Colla L, Gondolini A, Fabrizio M. The synthesis and effect of copper nanoparticles on the tribological properties of lubricant oils. IEEE Trans Nanotechnol. 2013;12(5):751–9.

Duangthongsuk W, Wongwises S. Measurement of temperature-dependent thermal conductivity and viscosity of TiO2–water nanofluids. Exp Therm Fluid Sci. 2009;33(4):706–14.

Alirezaie A, Saedodin S, Esfe MH, Rostamian SH. Investigation of rheological behavior of MWCNT (COOH-functionalized)/MgO-engine oil hybrid nanofluids and modelling the results with artificial neural networks. J Mol Liq. 2017;241:173–81.

Jabbari F, Rajabpour A, Saedodin S. Thermal conductivity and viscosity of nanofluids: a review of recent molecular dynamics studies. Chem Eng Sci. 2017;174:67–81.

Sepyani K, Afrand M, Esfe MH. An experimental evaluation of the effect of ZnO nanoparticles on the rheological behavior of engine oil. J Mol Liq. 2017;236:198–204.

Kole M, Dey T. Effect of aggregation on the viscosity of copper oxide–gear oil nanofluids. Int J Therm Sci. 2011;50(9):1741–7.

Esfe MH, Zabihi F, Rostamian H, Esfandeh S. Experimental investigation, model development of the non-Newtonian behavior of CuO–MWCNT-10w40 nano-lubricant for lubrication purposes. J Mol Liq. 2017;249:677–87.

Esfe MH, Saedodin S, Wongwises S, Toghraie D. An experimental study on the effect of diameter on thermal conductivity and dynamic viscosity of Fe/water nanofluids. J Therm Anal Calorim. 2015;119(3):1817–24.

Esfe MH, Saedodin S, Asadi A, Karimipour A. Thermal conductivity and viscosity of Mg(OH)2–ethylene glycol nanofluids. J Therm Anal Calorim. 2015;120(2):1145–9.

Kulkarni DP, Das DK, Chukwu GA. Temperature dependent rheological property of copper oxide nanoparticles suspension (nanofluid). J Nanosci Nanotechnol. 2006;6(4):1150–4.

Namburu PK, Kulkarni DP, Misra D, Das DK. Viscosity of copper oxide nanoparticles dispersed in ethylene glycol and water mixture. Exp Therm Fluid Sci. 2007;32(2):397–402.

Pakdaman MF, Akhavan-Behabadi M, Razi P. An experimental investigation on thermo-physical properties and overall performance of MWCNT/heat transfer oil nanofluid flow inside vertical helically coiled tubes. Exp Therm Fluid Sci. 2012;40:103–11.

Ahmadi H, Rashidi A, Nouralishahi A, Mohtasebi SS. Preparation and thermal properties of oil-based nanofluid from multi-walled carbon nanotubes and engine oil as nano-lubricant. Int Commun Heat Mass Transf. 2013;46:142–7.

Chen H, Ding Y, He Y, Tan C. Rheological behaviour of ethylene glycol based titania nanofluids. Chem Phys Lett. 2007;444(4):333–7.

Kole M, Dey T. Viscosity of alumina nanoparticles dispersed in car engine coolant. Exp Therm Fluid Sci. 2010;34(6):677–83.

Esfe MH, Bahiraei M, Hajmohammad MH, Afrand M. Rheological characteristics of MgO/oil nanolubricants: experimental study and neural network modeling. Int Commun Heat Mass Transf. 2017;86:245–52.

Saeedinia M, Akhavan-Behabadi M, Razi P. Thermal and rheological characteristics of CuO–base oil nanofluid flow inside a circular tube. Int Commun Heat Mass Transf. 2012;39(1):152–9.

Aberoumand S, Jafarimoghaddam A, Moravej M, Aberoumand H, Javaherdeh K. Experimental study on the rheological behavior of silver-heat transfer oil nanofluid and suggesting two empirical based correlations for thermal conductivity and viscosity of oil based nanofluids. Appl Therm Eng. 2016;101:362–72.

Anoop K, Sadr R, Al-Jubouri M, Amani M. Rheology of mineral oil-SiO2 nanofluids at high pressure and high temperatures. Int J Therm Sci. 2014;77:108–15.

Tadjarodi A, Zabihi F. Thermal conductivity studies of novel nanofluids based on metallic silver decorated mesoporous silica nanoparticles. Mater Res Bull. 2013;48(10):4150–6.

Nikkam N, Saleemi M, Toprak M, Li S, Muhammed M, Haghighi E, et al. Novel nanofluids based on mesoporous silica for enhanced heat transfer. J Nanopart Res. 2011;13(11):6201–6.

Lázár K, Szegedi Á, Pál-Borbély G, Kotasthane A, Fejes P. Changes in states of substituted iron in microporous (MFI analogue) and mesoporous (MCM-41) hosts exposed to redox conditions. Catal Today. 2005;110(3):239–46.

Xu W, Gao Q, Xu Y, Wu D, Sun Y, Shen W, et al. Controllable release of ibuprofen from size-adjustable and surface hydrophobic mesoporous silica spheres. Powder Technol. 2009;191(1):13–20.

Deng G, Markowitz MA, Kust PR, Gaber BP. Control of surface expression of functional groups on silica particles. Mater Sci Eng C. 2000;11(2):165–72.

Manzano M, Aina V, Arean C, Balas F, Cauda V, Colilla M, et al. Studies on MCM-41 mesoporous silica for drug delivery: effect of particle morphology and amine functionalization. Chem Eng J. 2008;137(1):30–7.

Cauda V, Schlossbauer A, Bein T. Bio-degradation study of colloidal mesoporous silica nanoparticles: effect of surface functionalization with organo-silanes and poly (ethylene glycol). Microporous Mesoporous Mater. 2010;132(1):60–71.

Fox RW, McDonald AT, Pritchard PJ. Introduction to fluid dynamics. New York: Wiley; 2004.

Einstein A. Eine neue bestimmung der moleküldimensionen. Ann Phys. 1906;324(2):289–306.

Esfe MH, Afrand M, Yan W-M, Yarmand H, Toghraie D, Dahari M. Effects of temperature and concentration on rheological behavior of MWCNTs/SiO2 (20–80)-SAE40 hybrid nano-lubricant. Int Commun Heat Mass Transf. 2016;76:133–8.

Afrand M, Najafabadi KN, Akbari M. Effects of temperature and solid volume fraction on viscosity of SiO2–MWCNTs/SAE40 hybrid nanofluid as a coolant and lubricant in heat engines. Appl Therm Eng. 2016;102:45–54.

Dardan E, Afrand M, Isfahani AM. Effect of suspending hybrid nano-additives on rheological behavior of engine oil and pumping power. Appl Therm Eng. 2016;109:524–34.

Vakili-Nezhaad G, Dorany A. Investigation of the effect of multiwalled carbon nanotubes on the viscosity index of lube oil cuts. Chem Eng Commun. 2009;196(9):997–1007.

Esfe MH, Afrand M, Rostamian SH, Toghraie D. Examination of rheological behavior of MWCNTs/ZnO-SAE40 hybrid nano-lubricants under various temperatures and solid volume fractions. Exp Therm Fluid Sci. 2017;80:384–90.

Acknowledgements

Special thanks to the Science and Technology Park of Semnan University, which provided the conditions for this research.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Saedodin, S., Kashefi, M.H. & Bahrami, Z. Experimental study on the rheological behavior of nanolubricant-containing MCM-41 nanoparticles with viscosity measurement. J Therm Anal Calorim 137, 1499–1511 (2019). https://doi.org/10.1007/s10973-019-08074-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-019-08074-2