Abstract

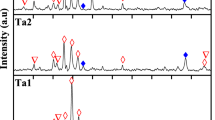

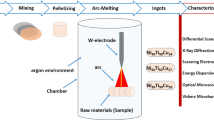

In this study, CuAl13−xTax (% mass x = 1; 1.5; 2; 2.5) shape-memory alloys were produced through arc-melting method. Phase transformation temperatures were investigated by using differential scanning calorimetry (DSC) and thermogravimetric analysis. Microstructures were examined with the aid of optical microscopy, scanning electron microscopy–energy-dispersive X-ray (SEM–EDX) and X-ray diffraction (XRD). The ratios of electron per atom (e/a) for CuAl13−xTa1, CuAl13−xTa1.5, CuAl13−xTa2 and CuAl13−xTa2.5 were calculated as 1.52, 1.51, 1.50 and 1.49, respectively. DSC results showed that CuAlTa alloys belong to high-temperature shape-memory alloys. Also, it was identified that these alloys demonstrate \(2{\text{H}}(\upgamma_{1}^{\prime } ) \to {\text{DO}}_{3} (\upbeta_{1} ) \to 18{\text{R}}(\upbeta_{1}^{\prime } )\) phase transformation. It was observed that both phase transformation temperature and oxidation sensitivity of the samples decreased with the increase in the amount of Ta. In the XRD analysis of CuAlTa HTSMA alloys, some phases were observed, including \(\upgamma^{\prime } ,\;\upbeta^{\prime }\) Cu9Al4, CuAl and Ta2Al3. These phases were supported by SEM–EDX results. The micro-hardness values of the alloys were increased by increasing Ta content.

Similar content being viewed by others

References

Addington M, Schodek D. Smart materials and technologies in architecture: for the architecture and design professions. London: Routledge; 2012.

Dagdelen F, et al. Influence of Ni addition and heat treatment on phase transformation temperatures and microstructures of a ternary CuAlCr alloy. Eur Phys J Plus. 2019;134(2):66.

Qader IN, Kök M, Dağdelen F. Effect of heat treatment on thermodynamics parameters, crystal and microstructure of (Cu–Al–Ni–Hf) shape memory alloy. Phys B Condens Matter. 2019;553:1–5.

Kajiwara S. Characteristic features of shape memory effect and related transformation behavior in Fe-based alloys. Mater Sci Eng, A. 1999;273:67–88.

Alaneme KK, Okotete EA. Reconciling viability and cost-effective shape memory alloy options—a review of copper and iron based shape memory metallic systems. Eng Sci Technol Int J. 2016;19(3):1582–92.

Melton K. Ni–Ti based shape memory alloys. Eng Asp Shape Mem Alloys. 1990;344:21–5.

Lexcellent C. Shape-memory alloys handbook. New York: Wiley; 2013.

Tang S, Chung C, Liu W. Preparation of CuAlNi-based shape memory alloys by mechanical alloying and powder metallurgy method. J Mater Process Technol. 1997;63(1–3):307–12.

Wang C, et al. A new type of Cu–Al–Ta shape memory alloy with high martensitic transformation temperature. Smart Mater Struct. 2013;23(2):025018.

Manzoni A, et al. Shape recovery in high temperature shape memory alloys based on the Ru–Nb and Ru–Ta systems. In: European symposium on martensitic transformations. EDP Sciences. 2009.

Van Humbeeck J, Stalmans R. Shape memory alloys, types and functionalities. In: Encyclopedia of smart materials. 2002.

Miura S, Morita Y, Nakanishi N. Superelasticity and shape memory effect in Cu–Sn alloys. In: Shape memory effects in alloys. Berlin: Springer; 1975. p. 389–405.

Ahlers M. Martensite and equilibrium phases in Cu–Zn and Cu–Zn–Al alloys. Prog Mater Sci. 1986;30(3):135–86.

Perkins J. Shape memory effects in alloys. Berlin: Springer; 2012.

Duerig TW, Melton K, Stöckel D. Engineering aspects of shape memory alloys. London: Butterworth-Heinemann; 2013.

Duerig TW, Albrecht J, Gessinger GH. A shape-memory alloy for high-temperature applications. JOM. 1982;34(12):14–20.

Sutou Y, et al. Characteristics of Cu–Al–Mn-based shape memory alloys and their applications. Mater Sci Eng, A. 2004;378(1):278–82.

Raju T, Sampath V. Influence of aluminium and iron contents on the transformation temperatures of Cu–Al–Fe shape memory alloys. Trans Indian Inst Met. 2011;64(1–2):165.

Schick JR, Hartl DJ, Lagoudas DC. Incorporation of shape memory alloy actuators into morphing aerostructures. In: Morphing aerospace vehicles and structures. 2012. p. 231-260.

Ionaitis R, Kotov V, Shchukin I. Application of shape-memory alloys in nuclear power. At Energy. 1995;79(4):712–4.

Hartl DJ, Lagoudas DC. Aerospace applications of shape memory alloys. Proc Inst Mech Eng Part G J Aerosp Eng. 2007;221(4):535–52.

Adorno A, Silva R. Effect of Ag additions on the reverse martensitic transformation in the Cu–10 mass% Al alloy. J Therm Anal Calorim. 2006;83(1):241–6.

Tadaki T. Cu-based shape memory alloys. In: Shape memory materials. 1998. p. 97–116.

Yang S, et al. Microstructure characterization, stress–strain behavior, superelasticity and shape memory effect of Cu–Al–Mn–Cr shape memory alloys. J Mater Sci. 2017;52(10):5917–27.

Cenoz I, Gutierrez M. Phase transformations in Cu–Al alloy. Met Sci Heat Treat. 2011;53(5–6):265–9.

Aydoğdu Y, et al. Thermal properties, microstructure and microhardness of Cu–Al–Co shape memory alloy system. Trans Indian Inst Met. 2014;67(4):595–600.

Silva R, et al. Characteristics of the Cu–18.84 at.% Al–10.28 at.% Mn–1.57 at.% Ag alloy after slow cooling from high temperatures. J Therm Anal Calorim. 2015;121(3):1233–8.

Salzbrenner R, Cohen M. On the thermodynamics of thermoelastic martensitic transformations. Acta Metall. 1979;27(5):739–48.

Kök M, Aydoğdu Y. Effect of composition on the thermal behavior of NiMnGa alloys. J Therm Anal Calorim. 2013;113(2):859–63.

Malkoc T, Dagdelen F. Production of CoAl and CoAlCr FSMAs and determination of their thermal, microstructure, and magnetic properties. J Therm Anal Calorim. 2019;135:1–6.

Yildiz K, Kök M, Dağdelen F. Cobalt addition effects on martensitic transformation and microstructural properties of high-temperature Cu–Al–Fe shape-memory alloys. J Therm Anal Calorim. 2015;120(2):1227–32.

Kwarciak J, Bojarski Z, Morawiec H. Phase transformation in martensite of Cu–12.4% Al. J Mater Sci. 1986;21(3):788–92.

Liu X, et al. Phase equilibria in the Cu-rich portion of the Cu–Al binary system. J Alloys Compd. 1998;264(1–2):201–8.

Prashantha S, Mallikarjun U, Shashidhara S. Effect of ageing on shape memory effect and transformation temperature on Cu–Al–Be shape memory alloy. Procedia Mater Sci. 2014;5:567–74.

Soliman H, Habib N. Effect of ageing treatment on hardness of Cu–12.5 wt% Al shape memory alloy. Indian J Phys. 2014;88(8):803–12.

Dagdelen F, Ercan E. The surface oxidation behavior of Ni–45.16%Ti shape memory alloys at different temperatures. J Therm Anal Calorim. 2014;115(1):561–5.

Saud SN, et al. Effect of Ta additions on the microstructure, damping, and shape memory behaviour of prealloyed Cu–Al–Ni shape memory alloys. Scanning. 2017. https://doi.org/10.1155/2017/1789454.

Silva R, et al. Investigation of thermal, mechanical and magnetic behaviors of the Cu–11% Al alloy with Ag and Mn additions. Mater Character. 2013;75:194–9.

Acknowledgements

This work is supported by Firat University Research Project Unit under Project No FF. 16.41.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Ercan, E., Dagdelen, F. & Qader, I.N. Effect of tantalum contents on transformation temperatures, thermal behaviors and microstructure of CuAlTa HTSMAs. J Therm Anal Calorim 139, 29–36 (2020). https://doi.org/10.1007/s10973-019-08418-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-019-08418-y