Abstract

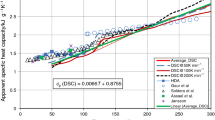

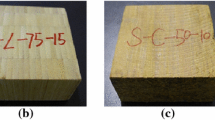

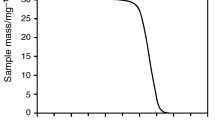

A comprehensive study has been conducted on some charring materials frequently found in buildings to characterise pyrolysis and combustion parameters concerning the variations in heating rate, temperature and heat flux. Since these parameters are input for computational fluid dynamics (CFD)-based fire models, incorporation of the effects of heating rate and heat flux when simulating building fires may lead to better predictions of tenability conditions. Three common construction and building materials were selected, namely pine, cotton and wool, to characterise via experimental protocols which can serve as examples of future novel charring materials. Parameter values related to pyrolysis reactions were determined using thermogravimetric analysis and differential scanning calorimetry. The values of the combustion parameters were obtained using cone calorimetry. It was found that the variation in heating rate has a significant effect on the values of the pyrolysis parameters of the studied materials. The kinetic parameter and heat of reaction (HoR) values of pine increased with the increment in heating rate. Conversely, the kinetic parameter values of cotton and wool decreased as the heating rate increased, whereas the HoR values followed a similar incremental trend with the increasing heating rate. The variation in combustion parameter values varied concerning heat flux due to the presence of high moisture contents and possible variations in char development in all materials. As CFD-based fire models are currently widely used to design and assess performance-based building fire safety designs, to obtain better predictions of tenability conditions, a proposal for the optimised use of parameters is presented.

Similar content being viewed by others

Change history

28 November 2019

In the original publication of the article, Figure 3 was published incorrectly. The corrected Fig. 3 is given in this correction.

References

Abu Bakar AS, Cran M, Moinuddin KAM. Experimental investigation of effects of variation in heating rate, temperature and heat flux on fire properties of a non-charring polymer. J Therm Anal Calorim. 2019;137(2):447–59.

McGrattan K, Forney G. Fire dynamics simulator (version 4) user’s guide. 4th ed. Washington: US Government Printing Office; 2006.

Jiang Y. Decomposition, ignition and flame spread on furnishing materials. CESARE: Victoria University; 2006.

National Institute of S, Technology. Fire Dynamics Simulator (FDS) and Smokeview (SMV). National Institute of Standard and Technology; 2015.

Nguyen QT, Ngo TD, Bai Y, Tran P. Experimental and numerical investigations on the thermal response of multilayer glass fibre/unsaturated polyester/organoclay composite. Fire Mater. 2016;40(8):1047–69.

Nguyen QT, Tran P, Ngo TD, Tran PA, Mendis P. Experimental and computational investigations on fire resistance of GFRP composite for building façade. Compos B Eng. 2014;62:218–29.

Nguyen Q, Ngo T, Tran P, Mendis P, Zobec M, Aye L. Fire performance of prefabricated modular units using organoclay/glass fibre reinforced polymer composite. Constr Build Mater. 2016;129:204–15.

Xu Q, Jin C, Majlingova A, Restas A. Discuss the heat release capacity of polymer derived from microscale combustion calorimeter. J Therm Anal Calorim. 2018;133(1):649–57.

Ragland K, Aerts D, Baker A. Properties of wood for combustion analysis. Biores Technol. 1991;37(2):161–8.

Moriana R, Vilaplana F, Karlsson S, Ribes A. Correlation of chemical, structural and thermal properties of natural fibres for their sustainable exploitation. Carbohyd Polym. 2014;112:422–31.

Bauer K, Garbe D, Surburg H. Flavors and fragrance in Ullmann's encyclopedia of industrial chemistry. Germany: VCH Weinheim; 1988. p. 144.

International Organization for S, inventor ISO 5660 -1 : 2002 Reaction-to-fire tests—Heat release, smoke production and mass loss rate—Part 1: Heat release rate (cone calorimeter method). Switzerland 2002.

Tata J, Alongi J, Carosio F, Frache A. Optimization of the procedure to burn textile fabrics by cone calorimeter: part I. Combustion behavior of polyester. Fire Mater. 2011;35(6):397–409.

Abu-Bakar AS, Moinuddin KAM, editors. Effects of variation in heating rate, sample mass and nitrogen flow on chemical kinetics for pyrolysis 2012 December 3–7. In: 18th Australasian fluid mechanics conference: Launceston, TAS.

Wang B, Gao B, Zimmerman AR, Zheng Y, Lyu H. Novel biochar-impregnated calcium alginate beads with improved water holding and nutrient retention properties. J Environ Manag. 2018;209:105–11.

Zhu B, Haghi M, Nguyen A, Goud M, Yeung S, Young PM, et al. Delivery of theophylline as dry powder for inhalation. Asian J Pharm Sci. 2015;10(6):520–7.

American Society for Testing and Materials. ASTM 1354-04a, Standard Test Method for Heat and Visible Smoke Release Rates for Materials and Products Using an Oxygen Consumption Calorimeter: ASTM International, West Conshohocken, PA, www.astm.org; 2004.

Vyazovkin S. Isoconversional kinetics of thermally stimulated processes. Switzerland: Springer; 2015.

Wampler TP. Applied pyrolysis handbook. Boca Raton: CRC Press; 2006.

Viswanath SG, Gupta MC. Estimation of nonisothermal kinetic parameters from a TG curve by the methods of overdetermined system and inflection point. Thermochim Acta. 1996;285(2):259–67.

Lautenberger C, Rein G, Fernandez-Pello C. The application of a genetic algorithm to estimate material properties for fire modeling from bench-scale fire test data. Fire Safety J. 2006;41(3):204–14.

Opfermann J. Kinetic analysis using multivariate non-linear regression. I. Basic concepts. J Therm Anal Calorim. 2000;60(2):641–58.

Abu-Bakar AS. Characterization of fire properties for coupled pyrolysis and combustion simulation and their optimised use. College of Engineering and Science: Victoria University; 2015. .

Matala A. estimation of solid phase reaction parameters for fire simulation. Faculty of Information and Natural Sciences: Helsinki University of Technology; 2008.

Grønli MG, Várhegyi G, Di Blasi C. Thermogravimetric analysis and devolatilization kinetics of wood. Ind Eng Chem Res. 2002;41(17):4201–8.

Liu N, Fan W. Modelling the thermal decompositions of wood and leaves under a nitrogen atmosphere. Fire Mater. 1998;22(3):103–8.

Mishra G, Kumar J, Bhaskar T. Kinetic studies on the pyrolysis of pinewood. Bioresour Technol. 2015;182:282–8.

Slopiecka K, Bartocci P, Fantozzi F. Thermogravimetric analysis and kinetic study of poplar wood pyrolysis. Appl Energy. 2012;97:491–7.

Wadhwani R, Sutherland D, Moinuddin KAM, Joseph P. Kinetics of pyrolysis of litter materials from pine and eucalyptus forests. J Therm Anal Calorim. 2017;130(3):2035–46.

Yao F, Wu Q, Lei Y, Guo W, Xu Y. Thermal decomposition kinetics of natural fibers: activation energy with dynamic thermogravimetric analysis. Polym Degrad Stab. 2008;93(1):90–8.

Missoum A, Gupta AK, Chen J. Global kinetics of the thermal decomposition of waste materials. July 27-August 1; Thirty-Second Intersociety Energy Conversion Engineering Conference (IECEC-97): Honolulu, HI, USA; 1997. p. 636–41.

Anca-Couce A, Zobel N, Berger A, Behrendt F. Smouldering of pine wood: kinetics and reaction heats. Combust Flame. 2012;159(4):1708–19.

Haseli Y, van Oijen JA, de Goey LPH. Modeling biomass particle pyrolysis with temperature-dependent heat of reactions. J Anal Appl Pyrolysis. 2011;90(2):140–54.

Mui ELK, Cheung WH, Lee VKC, McKay G. Kinetic study on bamboo pyrolysis. Ind Eng Chem Res. 2008;47(15):5710–22.

Quan C, Li A, Gao N. Thermogravimetric analysis and kinetic study on large particles of printed circuit board wastes. Waste Manag. 2009;29(8):2353–60.

Milosavljevic I, Oja V, Suuberg EM. Thermal effects in cellulose pyrolysis: relationship to char formation processes. Ind Eng Chem Res. 1996;35(3):653–62.

Faroq AA, Price D, Milnes GJ, Horrocks AR. Thermogravimetric analysis study of the mechanism of pyrolysis of untreated and flame retardant treated cotton fabrics under a continuous flow of nitrogen. Polym Degrad Stab. 1994;44(3):323–33.

Wakelyn PJ, Bertoniere NR, French AD, Thibodeaux DP, Triplett BA, Rousselle M-A, et al. Chapter 9 cotton fibers. In: Lewin M, editor. Handbook of fiber chemistry. 3rd ed. Boca Raton: CRC Press; 2006. p. 612.

Cao XX, Shen BX, Lu F, Yao Y, editors. Catalytic pyrolysis of cotton straw by zeolites and metal oxides. In: Proceedings of the 20th international conference on fluidized bed combustion; 2010: Springer.

Chizhik AI, Shabes SV, Tsyui LL, Tetereva NG. The use of spline approximation for the interpretation of results of thermal analysis. Polym Sci USSR. 1979;21(7):1846–50.

Tian CM, Zhang HY, Xu JZ, Pang XY, Guo HZ, Shi JR, et al. Studies on the flame retardation and thermal degradation of wool. J Text Inst. 1998;89(3):591–4.

Popescu C, Augustin P. Effect of chlorination treatment on the thermogravimetric behaviour of wool fibres. J Therm Anal Calorim. 1999;57(2):509–15.

Horrocks AR, Davies PJ. Char formation in flame-retarded wool fibres. Part 1. Effect of intumescent on thermogravimetric behaviour. Fire Mater. 2000;24(3):151–7.

Park D. Evaluation of the combustion characteristics of railroad waste using a cone calorimeter. Int J Environ Monit Anal. 2014;2(1):27–35.

Pottel H. The accumulation of flammable gases in cone calorimeter tests is responsible for flash ignition of wool and cotton samples. Fire Mater. 1996;20(2):107–9.

Donskoi E, McElwain DLS. Approximate modelling of coal pyrolysis. Fuel. 1999;78(7):825–35.

Li K-Y, Huang X, Fleischmann C, Rein G, Ji J. Pyrolysis of medium-density fiberboard: optimized search for kinetics scheme and parameters via a genetic algorithm driven by Kissinger’s method. Energy Fuels. 2014;28(9):6130–9.

Kissinger HE. Variation of peak temperature with heating rate in differential thermal analysis. J Res Natl Bur Stand. 1956;57(4):217–21.

Shi L, Chew MYL. A review of fire processes modeling of combustible materials under external heat flux. Fuel. 2013;106:30–50.

Acknowledgements

The authors wish to acknowledge the technical and financial assistance provided by Omnii Pty Ltd, Xtralis and Scientific Fire Services. The authors also acknowledge stimulating discussions with Dr Yun Jiang of Xtralis.

Funding

Ariza S. Abu-Bakar was a Ph.D. candidate of Victoria University funded by Universiti Sains Malaysia and currently employed by the same university.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Abu-Bakar, A.S., Cran, M.J., Wadhwani, R. et al. Characterisation of pyrolysis and combustion parameters of charring materials most frequently found in buildings. J Therm Anal Calorim 139, 2985–2999 (2020). https://doi.org/10.1007/s10973-019-08688-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-019-08688-6