Abstract

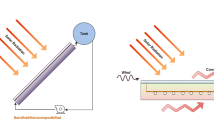

In the present study, the thermal efficiency, convective heat transfer and friction factor analysis are investigated for a flat plate solar collector with thermosyphon (natural circulation) system using water and nanodiamond–cobalt oxide hybrid nanofluids as the working fluids. The nanodiamond–cobalt oxide hybrid nanoparticles were synthesized using in situ growth and chemical co-precipitation method and characterized using X-ray diffraction, transmission electron microscope and vibrating sample magnetometer. The investigations were performed at different volume flow rates 0.56–1.35 L min−1 and various mass concentrations of 0.05–0.15%. The thermal conductivity and viscosity of nanofluids were measured experimentally at various mass concentrations and temperatures. Due to the augmented thermo-physical properties of hybrid nanofluids, the collector reached higher coefficient of heat transfer as well as improved thermal efficiency than the water data. Maximum thermal conductivity and viscosity enhancements are found to be 15.71% and 45.83% at particle loadings of 0.15% mass concentration and at a temperature of 60 °C. Results show the Nusselt number enhancement of 0.15% mass concentration of hybrid nanofluid is 21.23% with maximum friction factor penalty of 1.13 times against water data. The collector thermal efficiency is found to 59% for the case of 0.15% mass concentration of hybrid nanofluid, where the thermal efficiency of water is 48%. The empirical correlations were developed for Nusselt number and friction factor for collector with hybrid nanofluids within the deviation of ± 3%.

Similar content being viewed by others

Abbreviations

- \( A_{\rm c} \) :

-

Collector area (m2)

- \( C_{\rm p} \) :

-

Specific heat (J kg−1 K−1)

- \( D_{\rm i} \) :

-

Tube inner diameter (m)

- \( F_{\rm R} \) :

-

Heat removal factor

- \( G_{\rm Z} \) :

-

Graetz number, \( {\text{Re}} \Pr D_{\rm i} /L \)

- \( G_{\rm T} \) :

-

Global solar radiation (W m−2)

- \( h_{\rm i} \) :

-

Convective heat transfer coefficient (W m−2 K−1)

- \( L \) :

-

Tube length (m)

- \( \dot{m} \) :

-

Mass flow rate of fluid (kg s−1)

- \( Q \) :

-

Rate of heat gained (W)

- \( {\text{Re}} \) :

-

Reynolds number, \( 4\dot{m}/\pi D_{\rm i} \mu \)

- \( {\text{Pr}} \) :

-

Prandtl number, \( \mu C_{\rm p} /k \)

- \( T_{\rm a} \) :

-

Ambient temperature (K)

- \( T_{\rm i} \) :

-

Inlet temperature of the fluid (K)

- \( T_{\rm m} \) :

-

Mean temperature of the fluid (K), \( T_{\rm o} + T_{\rm i} /2 \)

- \( T_{\rm o} \) :

-

Outlet temperature of the fluid (K)

- \( T_{\rm s} \) :

-

Surface temperature (K), \( (T_{1} + T_{2} + T_{3} + T_{4} + T_{5} + T_{6} + T_{7} + T_{8} + T_{9} )/9 \)

- \( U_{\rm o} \) :

-

Overall heat transfer coefficient (W m−2 K−1)

- \( U_{\rm L} \) :

-

Overall loss coefficient of solar collector (W m−2 K−1)

- \( \Delta P \) :

-

Pressure drop (Pa)

- \( \tau \alpha \) :

-

Absorptance–transmittance product

- \( \eta_{\rm i} \) :

-

Instantaneous collector effectiveness

- \( \psi \) :

-

Mass concentration (%)

References

Choi SUS. Enhancing thermal conductivity of fluids with nanoparticles. In: Proceedings of the 1995 ASME international mechanical engineering congress and exposition San Francisco, CA, USA, 1995. p. 1–6.

Lee S, Choi SUS, Li S, Eastman JA. Measuring thermal conductivity of fluids containing oxide nanoparticles. J Heat Transf. 1999;121:280–9.

Sundar LS, Singh MK, Sousa ACM. Experimental investigation of Al2O3/water nanofluids on the effectiveness of solar flat-plate collectors with and without twisted tape inserts. Renew Energy. 2018;119:820–33.

Jouybari HJ, Saedodin S, Zamzamian A, Nimvari ME, Wongwises S. Effects of porous material and nanoparticles on the thermal performance of a flat plate solar collector: an experimental study. Renew Energy. 2017;114(Part B):1407–18.

Hawwash AA, Abdel Rahman AK, Nada SA, Ookawara S. Numerical investigation and experimental verification of performance enhancement of flat plate solar collector using nanofluids. Appl Therm Eng. 2018;130:363–74.

Okonkwo EC, Wole-Osho I, Kavaz D, Abidb M, Al-Ansari T. Thermodynamic evaluation and optimization of a flat plate collector operating with alumina and iron mono and hybrid nanofluids. Sustain Energy Technol Assess. 2020;37:100636.

Kiliç F, Menlik T, Sözen A. Effect of titanium dioxide/water nanofluid use on thermal performance of the flat plate solar collector. Sol Energy. 2018;164:101–8.

Ziyadanogullari NB, Yucel HL, Yildiz C. Thermal performance enhancement of flat-plate solar collectors by means of three different nanofluids. Therm Sci Eng Progress. 2018;8:55–65.

Sharafeldin MA, Gróf G. Experimental investigation of flat plate solar collector using CeO2–water nanofluid. Energy Convers Manag. 2018;155:32–41.

Stalin PMJ, Arjunan TV, Matheswaran MM, Dolli H, Sadanandam N. Energy, economic and environmental investigation of a flat plate solar collector with CeO2/water nanofluid. J Therm Anal Calorim. 2019. https://doi.org/10.1007/s10973-019-08670-2.

Choudhary S, Sachdeva S, Kumar P. Influence of stable zinc oxide nanofluid on thermal characteristics of flat plate solar collector. Renew Energy. 2020;152:1160–70.

Tong Y, Lee H, Kang W, Cho H. Energy and exergy comparison of a flat-plate solar collector using water, Al2O3 nanofluid, and CuO nanofluid. Appl Therm Eng. 2019;159:113959.

Choudhary S, Sachdeva A, Kumar P. Investigation of the stability of MgO nanofluid and its effect on the thermal performance of flat plate solar collector. Renew Energy. 2020;147:1801–14.

Verma SK, Tiwari AK, Chauhan DS. Experimental evaluation of flat plate solar collector using nanofluids. Energy Convers Manag. 2017;134:103–15.

Rajput NS, Shukla DD, Rajput D, Sharma SK. Performance analysis of flat plate solar collector using Al2O3/distilled water nanofluid: an experimental investigation. Mater Today Proc. 2019;10:52–9.

Anin Vincely D, Natarajan E. Experimental investigation of the solar FPC performance using graphene oxide nanofluid under forced circulation. Energy Convers Manag. 2016;117:1–11.

Ajiwiguna TA, Hamonangan T, Kirom MR. Experimental study of thermal efficiency on plate-fin solar thermal collector. ARPN J Eng Appl Sci. 2016;11:809–11.

Jani HK, Modi KV. A review on numerous means of enhancing heat transfer rate in solar-thermal based desalination devices. Renew Sustain Energy Rev. 2018;93:302–17.

Jani HK, Modi KV. Experimental performance evaluation of single basin dual slope solar still with circular and square cross-sectional hollow fins. Sol Energy. 2019;179:186–94.

Modi KV, Jani HK, Gamit ID. Impact of orientation and water depth on productivity of single-basin dual-slope solar still with Al2O3 and CuO nanoparticles. J Therm Anal Calorim. 2020. https://doi.org/10.1007/s10973-020-09351-1.

Sundar LS, Singh MK, Sousa ACM. Enhanced heat transfer and friction factor of MWCNT–Fe3O4/water hybrid nanofluids. Int Commun Heat Mass Transf. 2014;52:73–83.

Osho IW, Okonkwo EC, Kavaz D, Abbasoglu S. An experimental investigation into the effect of particle mixture ratio on specific heat capacity and dynamic viscosity of Al2O3–ZnO hybrid nanofluids. Powder Technol. 2020. https://doi.org/10.1016/j.powtec.2020.01.015.

Giwa SO, Sharifpur M, Meyer JP. Experimental study of thermo-convection performance of hybrid nanofluids of Al2O3–MWCNT/water in a differentially heated square cavity. Int J Heat Mass Transf. 2020;148:119072.

Li X, Zeng G, Lei X. The stability, optical properties and solar-thermal conversion performance of SiC–MWCNTs hybrid nanofluids for the direct absorption solar collector (DASC) application. Solar Energy Mater Solar Cells. 2018. https://doi.org/10.1016/j.solmat.2019.110323.

Verma SK, Tiwari SK, Tiwari AK, Chauhan DS. Performance analysis of hybrid nanofluids in flat plate solar collector as an advanced working fluid. Sol Energy. 2018;67:231–41.

Farajzadeh E, Movahed S, Hosseini R. Experimental and numerical investigations on the effect of Al2O3/TiO2–H2O nanofluids on thermal efficiency of the flat plate solar collector. Renew Energy. 2018;118:122–30.

Sundar LS, Irurueta GO, Ramana EV, Singh MK, Sousa ACM. Thermal conductivity and viscosity of hybrid nanofluids prepared with magnetic nanodiamond–cobalt oxide (ND–Co3O4) nanocomposite. Case Stud Therm Eng. 2016;7:66–77.

Makhlouf SA. Magnetic properties of Co3O4 nanoparticles. J Magn Magn Mater. 2008;246(1–2):184–90.

Smith JM, Van Ness HC. Introduction to chemical thermodynamics. New York: McGraw-Hill Science; 2000.

Pak BC, Cho YI. Hydrodynamic and heat transfer study of dispersed fluids with submicron metallic oxide particles. Exp Heat Transf. 1998;11:151–70.

Whillier A. Design factors influencing collector performance, low temperature engineering. In: Application of solar energy, ASHRAE, New York, 1967.

Hottel HC, Whillier A. Evaluation of fat plate collector performance. In: Trans. conf. on the use of solar energy. University of Arizona Press, 1958.

Bliss RW. The derivation of several plate effectiveness factors useful in the design of flat plate solar heat collectors. Sol Energy. 1959;3:55–64.

Incropera FP, DeWitt DP, Bergman TL, Lavine AS. Fundamentals of heat and mass transfer. 6th ed. Hoboken: Wiley; 2006.

Sieder EN, Tate GE. Heat transfer and pressure drop of liquids in tubes. Ind Eng Chem. 1936;28:1429–39.

Acknowledgements

The author LSS (Ref. 045-88-ARH/2018) acknowledge Fundação para a Ciencia e a Tecnologia, Portugal, for their projects, and the work was supported by the Projects UIDB/00481/2020, UIDP/00481/2020 and infrastructure support of CENTRO-01-0145-FEDER-022083.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Syam Sundar, L., Misganaw, A.H., Singh, M.K. et al. Efficiency analysis of thermosyphon solar flat plate collector with low mass concentrations of ND–Co3O4 hybrid nanofluids: an experimental study. J Therm Anal Calorim 143, 959–972 (2021). https://doi.org/10.1007/s10973-020-10176-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-020-10176-1