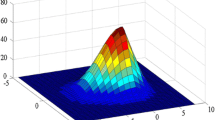

We propose a method for the determination of the triaxial stressed state in the process of butt welding by a rapidly moving heat source and construct three-dimensional distributions of the components of the stress field for welded joints of 1201-Т aluminum alloy with different thicknesses made by the electronbeam welding. It is shown that the residual transverse σ xx and axial σ yy stresses are maximum and constitute 80–90% of the ultimate strength of the metal. It is shown that, for plates of smaller thickness, the residual stresses are higher due the smaller sizes of the heat-and-deformation affected zone.

Similar content being viewed by others

References

V. R. Skal’s’kyi and I. M. Lyasota, “Estimation of the heat-affected zone for the electron-beam welding of plates,” Fiz.-Khim. Mekh. Mater., 46, No. 1, 103–109 (2010); English translation: Mater. Sci., 46, No. 1, 115–123 (2010).

I. P. Trochun, Internal Forces and Deformations in Welding [in Russian], Gos. Nauch.-Tekh. Izd. Mashinostr. Liter., Moscow (1964).

G. A. Nikolaev, Welded Structures [in Russian], Mashgiz, Moscow (1962).

G. B. Talypov, Welding Strains and Stresses [in Russian], Mashinostroenie, Leningrad (1974).

V. I. Makhnenko, Computational Methods of Investigating the Kinetics of Welding Stresses and Strains [in Russian], Naukova Dumka, Kiev (1976).

V. I. Makhnenko and L. A. Egorova, “Computational methods for evaluating stresses and strains in the zone of longitudinal welds of cylindrical shells,” Avtomat. Svarka, No. 3, 3–7 (1980).

D. Stamenković and I. Vasović, “Finite-element analysis of residual stress in butt welding two similar plates,” Sci. Tech. Rev., LIX, No. 1, 57–60 (2009).

L. Huo, F. Chen, Y. Zhang, et al., “Finite element numerical simulation of residual stresses on electron beam welded BT20 plates,” J. Mater. Sci. Technol., 20, No. 1, 117–120 (2004).

A. Bokota and L. Pekarskaya, “Numerical investigation of the stressed state of welded joints made by laser welding,” in: V. I. Makhnenko (editor), Mathematical Modeling and Information Technologies in Welding and Related Processes. Proc. of the Int. Conf. (September 16–20, 2002, Katsiveli, Crimea) [in Russian], Kiev (2002), pp. 131–135.

V. A. Vinokurov and A. G. Grigoryants, Theory of Welding Strains and Stresses [in Russian], Mashinostroenie, Moscow (1984).

N. O. Okerblom, Welding Strains and Stresses [in Russian], Mashinostroenie, Moscow (1948).

V. Osadchuk and L. Tsymbalyuk, “Features of the residual stress distribution in a layer with a rectilinear weld made by a concentrated heat source,” Mashynoznavstvo, No. 3, 13–17 (2003).

V. Osadchuk, Yu. Banakhevych and L. Tsymbalyuk, “Influence of the width of the zone of plastic strains on the distribution of triaxial residual stresses in a plate with a multilayer rectilinear weld,” Mashynoznavstvo, No. 2, 13–17 (2008).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Fizyko-Khimichna Mekhanika Materialiv, Vol. 48, No. 3, pp. 87–93, May–June, 2012.

Rights and permissions

About this article

Cite this article

Skal’s’kyi, V.R., Rudavs’kyi, D.V. & Lyasota, I.M. Numerical analysis of residual stresses near a weld in the course of electron-beam welding of thick plates. Mater Sci 48, 355–363 (2012). https://doi.org/10.1007/s11003-012-9513-y

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11003-012-9513-y