Abstract

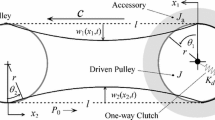

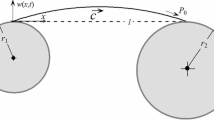

This paper presents constitutive modeling of dynamically loaded elastomeric products such as power transmission belts. During the normal operation of the belts certain segments of the belt structure are loaded with a tooth-like periodic (cyclic) loading. When the time-dependent properties of the elastomeric material “match” the time-scale of the dynamic loading a strain accumulation process occurs. The critical angular velocity is proportional to the ratio of the belt length to the common diameters of the pulleys. The magnitude of the strain accumulated in each loading cycle decreases with an increase in belt length. For a given belt geometry the critical angular velocity increases with the number of loading cycles. At the same time the magnitude of the accumulated strain decreases non-linearly as the number of loading cycles increases. However if the belt operates at or in the close vicinity of its critical angular velocity it will almost certainly fail!

The critical angular velocity depends on the material retardation time (location in the frequency spectrum), while the magnitude of the accumulated strain is dictated by the strength of the corresponding discrete spectrum lines. Thus, the mechanical spectrum of the elastomeric material from which the belt is constructed is the most important material function for predicting the durability of drive belts and similarly dynamically loaded elastomeric products.

Similar content being viewed by others

References

Andre, N., Cailletaud, G., Piques, R.: Haigh diagram for fatigue crack initiation prediction of natural rubber components. Kautschuk Gummi Kunststoffe 52(2), 120–123 (1999)

Childs, T.H.C., Dalgarno, K.W., Hojjati, M.H., Tutt, M.J., Day, A.J.: The meshing of timing belt teeth in pulley grooves. Proc. Inst. Mech. Eng. Part D-J. Automobile Eng. 211(3), 205–218 (1997)

Dalgarno, K.W., Childs, T.H.C., Day, A.J., Hojjati, M.H.R., Moore, B., Yu, D.Q.: Mechanical properties of elastomer compounds in synchronous and V-ribbed belts. Kautschuk Gummi Kunststoffe 50(4), 299–303 (1997)

Dalgarno, K.W., Day, A.J., Childs, T.H.C., Moore, R.B.: Stiffness loss of synchronous belts. Compos. Part B Eng. 29(3), 217–222 (1998)

Dalgarno, K.W.: Power transmission belt performance and failure. Rubber Chem. Technol. 71(3), 619–636 (1998)

Emri, I., Prodan, T.: A measuring system for bulk and shear characterization of polymers. Exp. Mech. 46(4), 429–439 (2006)

Friedrich, K.: Mesoscopic aspects of polymer composites: processing, structure and properties. J. Mater. Sci. 33(23), 5535–5556 (1998)

Gurvich, M.R., Andonian, A.T., Kim, S.L.: Hysteretic energy loss in cord/rubber composites under 2-D cyclic loading. Rubber Chem. Technol. 74(5), 871–882 (2001)

Huang, Y.S., Yeoh, O.H.: Crack initiation and propagation in model cord-rubber composites. Rubber Chem. Technol. 62(4), 709–731 (1989)

Iizuka, H., Gerbert, G., Childs, T.H.C.: Fatigue damage prediction in synchronous belts. J. Mech. Des. 121(2), 280–288 (1999)

Iizuka, H., Watanabe, K., Mashimo, S.: Observations of Fatigue Failure in Synchronous Belts. Fatigue Fract. Eng. Mater. Struct. 17(7), 783–790 (1994)

Kido, R., Kusano, T., Fujii, T.: A New Approach for Analyzing Load Distribution of Toothed Belts at Steady States using FEM. SAE Technical Paper Series 940690, 23–32 (1994)

Koyama, T., Kagotani, M., Shibata, T., Sato, S., Hoshiro, T.: A study on strength of toothed belt. 5. Effect of pitch difference on fatigue-strength of toothed belt. Bull. JSME Japan Soc. Mech. Eng. 23(181), 1240–1244 (1980)

Koyama, T., Kagotani, M., Shibata, T., Sato, S., Hoshiro, T.: A study on strength of toothed belt. 3. Fatigue-strength and features of fracture. Bull. JSME Japan Soc. Mech. Eng. 22(169), 988–993 (1979)

Kralj, A., Prodan, T., Emri, I.: An apparatus for measuring the effect of pressure on the time-dependent properties of polymers. J. Rheol. (N.Y. N.Y.) 45(4), 929–943 (2001)

Ku, B.H., Liu, D.S., Lee, B.L.: Fatigue of cord-rubber composites: III. Minimum stress effect. Rubber Chem. Technol. 71(5), 889–905 (1998)

Lee, B.L., Ku, B.H., Liu, D.S., Hippo, P.K.: Fatigue of cord-rubber composites: II. Strain-based failure criteria. Rubber Chem. Technol. 71(5), 866–888 (1998)

Lee, B.L., Liu, D.S., Chawla, M., Ulrich, P.C.: Fatigue of Cord-Rubber Composites. Rubber Chem. Technol. 67(5), 761–774 (1994)

Legorju-jago, K., Bathias, C.: Fatigue initiation and propagation in natural and synthetic rubbers. Int. J. Fatigue 24(2–4), 85–92 (2002)

Mars, W.V., Fatemi, A.: Fatigue crack nucleation and growth in filled natural rubber. Fatigue Fract. Eng. Mater. Struct. 26(9), 779–789 (2003)

Pidaparti, R.M.V., Kakarla, V.: Fracture analysis of delamination failure in angle-ply elastomer composites. Polym. Polym. Compos. 6(7), 439–445 (1998)

Pidaparti, R.M.V., May, A.W.: Micromechanical analysis of fatigue cracks in cord-rubber composites. Compos. Struct. 54(4), 459–465 (2001a)

Pidaparti, R.M.V., May, A.W.: Stress analysis of failures in cord-rubber composites. Polym. Polym. Compos. 9(1), 15–23 (2001b)

Tschoegl, N.W.: The Phenomenological Theory of Linear Viscoelastic Behavior: An Introduction. Springer-Verlag, Berlin, Heidelberg (1989)

Uchida, T., Yamaji, Y., Hanada, N.: Analysis of the Load on Each Tooth of a 4-Cycle Gasoline-Engine Cam Pulley. JSME Int. J. Ser. C Dyn. Control Robot. Des. Manuf. 36(4), 530–536 (1993)

Zhao, J., Ghebremeskel, G.N.: A review of some of the factors affecting fracture and fatigue in SBR and BR vulcanizates. Rubber Chem. Technol. 74(3), 409–427 (2001)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Emri, I., Kramar, J., Hribar, A. et al. Time-dependent constitutive modeling of drive belts – I. The effect of geometry and number of loading cycles. Mech Time-Depend Mater 10, 245–262 (2006). https://doi.org/10.1007/s11043-006-9021-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11043-006-9021-2