Abstract

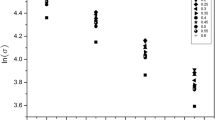

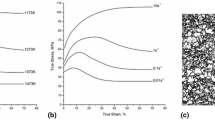

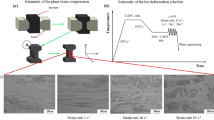

A constitutive relation is presented in this paper to describe the plastic behavior of ferritic steel over a broad range of temperatures and strain rates. The thermo-mechanical behavior of high strength low alloy (HSLA-65) and DH-63 naval structural steels is considered in this study at strains over 40%. The temperatures and strain rates are considered in the range where dynamic strain aging is not effective. The concept of thermal activation analysis as well as the dislocation interaction mechanism is used in developing the flow model for both the isothermal and adiabatic viscoplastic deformation. The flow stresses of the two steels are very sensitive to temperature and strain rate, the yield stresses increase with decreasing temperatures and increasing strain rates. That is, the thermal flow stress is mainly captured by the yield stresses while the hardening stresses are totally pertained to the athermal component of the flow stress. The proposed constitutive model predicts results that compare very well with the measured ones at initial temperature range of 77 K to 1000 K and strain rates between 0.001 s−1 and 8500 s−1 for both steels.

Similar content being viewed by others

References

Abed, F.H., Voyiadjis, G.Z.: Plastic deformation modeling of AL-6XN stainless steel at low and high strain rates and temperatures using a combination of BCC and FCC mechanisms of metals. Int. J. Plast. 21, 1618–1639 (2005a)

Abed, F.H., Voyiadjis, G.Z.: A consistent modified Zerilli-Armstrong flow stress model for BCC and FCC metals for elevated temperatures. Acta Mech. 175, 1–18 (2005b)

Børvik, T., Hopperstad, O.S., Berstad, T., Langseth, M.: A computational model of viscoplasticity and ductile damage for impact and penetration. Eur. J. Solid Mech. A 20, 685–712 (2001)

Guo, W.G., Nemat-Nasser, S.: Flow stress of Nitronic-50 stainless steel over a wide range of strain rates and temperatures. Mech. Mater. 38, 1090–103 (2006)

Hecker, S.S., Stout, M.G., Staudhammer, K.P., Smith, J.L.: Effects of strain state and strain rate on deformation induced transformation in 304 stainless steel. I. Magnetic measurements and mechanical behavior. Metall. Trans. A 13A, 619–626 (1982)

Ishikawa, K., Tanimura, S.: Strain rate sensitivity of flow stress at low temperature in 304N stainless steel. Int. J. Plast. 8, 947–958 (1992)

Johnson, G.R., Cook, W.H.: A constitutive model and data for metals subjected to large strains, high strain rates and high temperatures. In: Proceedings of the Seventh International Symposium on Ballistic, pp. 541–547. The Hague, The Netherlands (1983)

Kapoor, R., Nemat-Nasser, S.: Determination of temperature rise during high strain rate deformation. Mech. Mater. 27, 1–12 (1998)

Klepaczko, J.R.: Modeling of structural evolution at medium and high strain rates, FCC and BCC metals. In: Constitutive Relations and Their Physical Basis, pp. 387–395 (1987)

Klepaczko, J.R., Rezaig, B.: A numerical study of adiabatic shear bending in mild steel by dislocation mechanics based constitutive relations. Mech. Mater. 24, 125–139 (1996)

Klopp, R.W., Clifton, R.J., Shawki, T.: Pressure-shear impact and the dynamic viscoplastic response of metals. Mech. Mater. 4, 375–385 (1985)

Kocks, U.F., Argon, A.S., Ashby, M.F.: Thermodynamics and kinetics of slip. Prog. Mater. Sci. 19 (1975)

Kocks, U.F., Maddin, R.: Observations on the deformation of niobium. Acta Metall. 4, 92 (1956)

Krauss, G.: Microstructures, Processing, and Properties of Steel. ASM Handbook 1, pp. 126–139 (1990)

Militzer, M., Hawbolt, E.B., Meadowcroft, T.R.: Microstructural model for hot strip rolling of high-strength low alloy steels. Metall. Trans. A 31A, 1247–1259 (2000)

Nemat-Nasser, S., Isaacs, J.: Direct measurement of isothermal flow stress of metals at elevated temperatures and high strain rates with application to Ta and Ta-W alloys. Acta Metall. 45, 907–919 (1997)

Nemat-Nasser, S., Guo, W.G.: Thermomechanical response of DH-36 structural steel over a wide range of strain rates and temperatures. Mech. Mater. 35, 1023–47 (2003)

Nemat-Nasser, S., Guo, W.G.: Thermomechanical response of HSLA-65 steel plates: experiments and modelling. Mech. Mater. 37, 379–405 (2005)

Orowan, E.: Discussion in Symposium on Internal Stresses in Metals and Alloys, p. 451. Institute of Metals, London (1948)

Perzyna, P.: Fundamental problems in viscoplasticity. Adv. Appl. Mech. 9, 243–377 (1966)

Stout, M.G., Follansbee, P.S.: Strain rate sensitivity, strain hardening, and yield behavior of 304L stainless steel. Trans. ASME, J. Eng. Mater. Technol. 108, 119–132 (1986)

Taylor, G.I.: Plastic strain in metals. J. Inst. Met. 62, 307–324 (1938)

Voyiadjis, G.Z., Abed, F.H.: Microstructures based models for bcc and fcc metal with temperature and strain rate dependency. Mech. Mater. 37, 355–378 (2005a)

Voyiadjis, G.Z., Abed, F.H.: Effect of dislocation density evolution on the thermo-mechanical response of metals with different crystal structures at low and high strain rates and temperatures. Arch. Mech. 57, 299–343 (2005b)

Voyiadjis, G.Z., Abed, F.H.: Implicit algorithm for finite deformation hypoelsto-viscoplasticity in FCC metals. Int. J. Numer. Methods Eng. 67, 933–955 (2006)

Wang, W.M., Sluys, L.J., de Borst, R.: Viscoplasticity for instabilities due to strain softening and strain-rate softening. Int. J. Numer. Methods Eng. 40, 3839–3864 (1997)

Zener, C., Hollomom, J.H.: High speed deformation of metals. J. Appl. Phys. 15, 22–32 (1944)

Zerilli, F.J., Armstrong, R.W.: Dislocation-mechanics-based constitutive relations for material dynamics calculation. J. Appl. Phys. 5, 1816–1825 (1987)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Abed, F.H. Constitutive modeling of the mechanical behavior of high strength ferritic steels for static and dynamic applications. Mech Time-Depend Mater 14, 329–345 (2010). https://doi.org/10.1007/s11043-010-9112-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11043-010-9112-y