Abstract

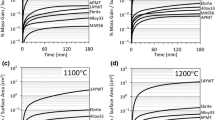

A steam oxidation test was conducted at 267 ± 17 bar and 670 °C for 293 h. A comparison test was run at 1 bar. All of the alloys showed an increase in scale thickness and oxidation rate with pressure, and TP304H and IN625 had very large increases. Fine-grained TP304H at 267 bar behaved like a coarse grained alloy, indicative of high pressure increasing the critical Cr level needed to form and maintain a chromia scale. At 267 bar H230, H263, H282, IN617 and IN740 had kp values a factor of one–to-two orders of magnitude higher than at 1 bar. IN625 had a four order of magnitude increase in kp at 267 bar compared to 1 bar. Possible causes for increased oxidation rates with increased pressure were examined, including increased solid state diffusion within the oxide scale and increased critical Cr content to establish and maintain a chromia scale.

Similar content being viewed by others

References

R. Dennis, “The DOE Turbine Program: Overall Program Description,” The Gas Turbine Handbook, Chapter 6.0.1 (National Energy Technology Laboratory, 2006), http://www.netl.doe.gov/research/coal/energy-systems/turbines/reference-shelf/handbook. Accessed 1 Aug 2014.

“U.S. Department of Energy and Ohio Coal Development Office Advanced Ultra-Supercritical Materials Project for Boilers and Steam Turbines: Summary of Results” (Report 1022770, Electric Power Research Institute, March 2011).

R. Viswanathan, A. F. Armor and G. Booras, A Critical Look at Supercritical Power Plants. Power 148, (3), 42–49 (2004).

“Thermophysical Properties of Fluid Systems,” National Institute of Standards and Technology, 2011, http://webbook.nist.gov/chemistry/fluid/. Accessed 1 Aug 2014.

G. R. Holcomb, Steam Oxidation and Chromia Evaporation in Ultra-Supercritical Steam Boilers and Turbines. Journal of the Electrochemical Society 156, (9), C292–C297 (2009).

M. Lukaszewicz, N. J. Simms, T. Dudziak and J. R. Nicholls, Effect of Steam Flow Rate and Sample Orientation on Steam Oxidation of Ferritic and Austenitic Steels at 650 and 700 °C. Oxidation of Metals 79, (5–6), 473–483 (2013).

S. Osgerby and J. Quadakkers, The Influence of Laboratory Test Procedures on Scale Growth Kinetics and Microstructure during Steam Oxidation Testing. Materials at High Temperature 22, (1/2), 27–33 (2005).

I. G. Wright, J. Y. Howe and A. S. Sabau, Morphological Evolution of Oxide Scales Grown on Ferritic Steels in Steam. Materials at High Temperatures 26, (2), 105–111 (2009).

I. G. Wright and R. B. Dooley, Steam-side Scale Morphologies Associated with Scale Exfoliation from Ferritic Steel T22. Materials at High Temperatures 30, (3), 168–182 (2013).

I. G. Wright, P. F. Tortorelli, M. Schütze, “Oxide Growth and Exfoliation on Alloys Exposed to Steam” (Report 1013666, Electric Power Research Institute, 2007).

I. G. Wright and R. B. Dooley, A Review of the Oxidation Behaviour of Structural Alloys in Steam. International Materials Reviews 55, (3), 129–167 (2010).

P. Banks, J. H. B. Lowick and P. Hurst, “Further Results for the Oxidation of Ferritic Steels in Steam” (Report ND-R-1012R, United Kingdom Atomic Energy Authority, 1984).

R. Paterson, R. Moser and T. R. Rettig, “Oxidation of Boiler Tubing,” Proceedings of the Electric Power Research Institute - VGB PowerTech International Conference on Interaction of Iron-based Materials with Water and Steam, eds. R. B. Dooley and A. Bursik (Heidelberg, Germany, Report TR-102101, 8-1–8-5, Electric Power Research Institute, June 1992).

J. C. Griess, J. M. Devan and W. A. Maxwell, Effect of a high heat flux on the corrosion of 2.25Cr-1Mo steel in superheated steam. Materials Performance 17, (1), 9–15 (1978).

V. Lepingle, G. Louis, D. Petelot, B. Lefebvre and J. C. Vaillant, High Temperature Corrosion Behaviour of some Boiler Steels in Pure Water Vapour. Materials Science Forum 369–372, 239–246 (2001).

P. Mayer and A. V. Manolescu, “The Role of Structural and Compositional Factors in Corrosion of Ferritic Steels in Steam,” High-temperature Corrosion, ed. R. A. Rapp (Houston, TX: National Association of Corrosion Engineers, 1983), pp. 368–379.

H. E. McCoy and B. McNabb, “Corrosion of Several Metals in Supercritical Steam at 538°C” (Report ORNL/TM-5781, Oak Ridge National Laboratory, 1977).

M. Sun, X. Wu, Z. Zhang and E.-H. Han, “Oxidation of 316 Stainless Steel in Supercritical Water”. Corrosion Science 51, (5), 1069–1072 (2009).

W. E. Ruther, R. R. Schlueter, R. H. Lee and R. K. Hart, Corrosion Behavior of Steels and Nickel Alloys in Superheated Steam. Corrosion 22, 147–155 (1965).

H. Matsuo, Y. Nishiyama, and Y. Yamadera, “Steam Oxidation Properties of Fine-grained Steels,” Proceedings of the 4th International Conference on Advances in Materials for Fossil Power Plants,” eds. R. Viswanathan, D. Gandy, and K. Coleman (Materials Park, OH: ASM International, 2005), pp. 441–450.

J. Sarver, private communication, (Babcock & Wilcox, to I. Wright, Oak Ridge National Laboratory, Sarver, 2009).

Thermo-Calc, “An Application for Thermodynamic Calculations,” Version 3.1, Foundation of Computational Thermodynamics, Stockholm, Sweden, 2013.

N. Saunders, “Ni-DATA,” Version 8, Thermotech Ltd, Surrey Technology Centre, Surrey, UK (2009).

H. L. Eiselstein and D. J. Tillack, The Invention and Definition of Alloy 625. in Superalloys 718, 625 and Various Derivatives, ed. E. A. Loria (TMS, Warrendale, 1991), pp. 1–14.

A. V. Shankar, K. B. S. Rao and S. K. Mannan, Microstructure and Mechanical Properties of Inconel 625 Superalloy. Journal of Nuclear Materials 288, (2–3), 222–232 (2001).

Per Kofstad, High Temperature Corrosion, Chapter 12 (New York, NY: Elsevier Applied Science,1988), pp. 400-402.

M. Montgomery and A. Karlsson, Survey of Oxidation in Steamside Conditions. VGB Kraftswerkstechnik 75, (3), 235–240 (1995).

G. H. Meier, K. Jung, N. Mu, N. M. Yanar, F. S. Pettit, J. Pirón Abellán, T. Olszewski, W. J. Quadakkers, and G. R. Holcomb, “Effect of Alloy Composition and Exposure Conditions on the Selective Oxidation Behavior of Ferritic Fe-Cr and Fe-Cr-X Alloys,” Oxidation of Metals, 74, 5–6(2010): pp. 319–340.

N. Mu, K. Y. Jung, N. M. Yanar, F. S. Pettit, G. R. Holcomb, B. H. Howard and G. H. Meier, The Effects of Water Vapor and Hydrogen on the High-Temperature Oxidation of Alloys. Oxidation of Metals 79, (5–6), 461–472 (2013).

E. Essuman, G. H. Meier, J. Żurek, M. Hänsel, L. Singheiser and W. J. Quadakkers, Enhanced Internal Oxidation as Trigger for Breakaway Oxidation of Fe-Cr Alloys in Gases Containing Water Vapor. Scripta Materialia 57, (9), 845–848 (2007).

M. H. B. Ani, T. Kodama, M. Ueda, K. Kawamura and T. Maruyama, The Effect of Water Vapor on High Temperature Oxidation of Fe-Cr Alloys at 1073 K. Materials Transactions 50, (11), 2656–2663 (2009).

C. W. Bale, A. D. Pelton, W. T. Thompson, G. Eriksson, K. Hack, P. Chartrand, S. Decterov, I-H. Jung, J. Melançon, and S. Petersen, FactSage 6.4, Thermfact and GTT-Technologies (2013).

Acknowledgments

This work was funded by the U.S. DOE Cross-cutting Technologies program at the National Energy Technology Laboratory. This report was prepared as an account of work sponsored by the United States Government. Neither the United States Government nor any agency thereof, nor any of their employees, makes any warranty, express or implied, or assumes any legal liability or responsibility for the accuracy, completeness, or usefulness of any information, apparatus, product, or process disclosed, or represents that its use would not infringe privately owned rights. Reference herein to any specific commercial product, process, or service by trade name, trademark, manufacturer, or otherwise does not necessarily constitute or imply its endorsement, recommendation, or favoring by the United States Government or any agency thereof.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Holcomb, G.R. High Pressure Steam Oxidation of Alloys for Advanced Ultra-Supercritical Conditions. Oxid Met 82, 271–295 (2014). https://doi.org/10.1007/s11085-014-9491-6

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11085-014-9491-6