The synthesis of Ti3AlC2 and Ti4AlN3 by isothermal sintering in vacuum is studied. The influence of the original powders, charge composition, and conditions of milling and sintering temperature on the phase composition of the material is analyzed. It is established that single-phase compounds form if and when the aluminum content in the original charge is higher than its stoichiometric amount by a factor of 1.4–1.6 for Ti3AlC2 and by a factor of 1.1–1.2 for Ti4AlN3. Conditions for producing single-phase Ti3AlC2 and Ti4AlN3 with the required TiC or TiN content were determined. The mechanical properties of the obtained materials in the 20–1300°C range were investigated. Results were compared with the mechanical properties of the previously obtained Ti3SiC2.

Similar content being viewed by others

Notes

*Density of titanium carbide nanolaminate is indicated in parentheses, g/cm3.

References

M. W. Barsoum, “The MN+1AXN phases: a new class of solids; thermodinamically stable nanolaminates,” Prog. Solid St. Chem., 28, 201–281 (2000).

V. W. Barsoum, T. El-Raghy, and M. Radovic, “Ti3SiC2: a layered machinable ductile carbide,” Interceram., 49, No. 4, 226–233 (2000).

B. J. Kooi, R. J. Poppen, N. J. M. Carvalho, et al., “Ti3SiC2: a damage tolerant ceramic studied with nanoindentations and transmission electron microscopy,” Acta Mater., 51, 2859–2872 (2003).

M. W. Barsoum and T. El-Raghy, “Room temperature ductile carbides,” Metall. Mater. Trans., A., 30A, 363–369 (1999).

I. I. Ivanova, A. N. Demidik, M. V. Karpets, et al., “Synthesis of titanium silicon carbide Ti3SiC2 under isothermal sintering,” Powder Metall. Met. Ceram., 51, No. 7/8, 437–446 (2012).

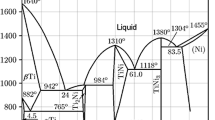

M. Pietzka and J. C. Schuster, The Ternary Boundary Phases of the Quaternary System Ti–Al–C–N, Leuven Proc., Part A, Commission of the European Communities, Belgium, Brussels (1992).

M. Pietzka and J. C. Schuster, “Summary of constitutional data on the Al–Ti–C system,” J. Phase Equilibr., 15, No. 4, 392–400 (1994).

N. V. Tzenov and M. W. Barsoum, “Synthesis and characterization of Ti3AlC2,” J. Amer. Ceram. Soc., No. 4, 825–832 (2000).

Shi-Bo Li, Hong-Xiang Zhai, Guo-Ping Bei, et al., “Synthesis and microstructure of Ti3AlC2 by mechanically activated sintering of elemental powders,” Ceram. Int., 33, 169–173 (2007).

Chen Yang, Songzhe Jin, Baoyan Liang, et al., “Synthesis of Ti3AlC2 by spark plasma sintering of mechanically milled 3Ti/xAl/2C powder mixtures,” J. All. Compd., 472, 79–83 (2009).

J. Zhu, L. Ye, and F. Wang, “Fabrication of Ti3AlC2/Al2O3 nanocomposite by a novel method,” Sci. Sintering, 43, 289–294 (2011).

S. A. Firstov, E. P. Pechkovskii, I. I. Ivanova, et al., “High-temperature mechanical properties of powder metallurgy porous lightweight titanium nanolaminates,” High Temp. Mat. Proc., 25, No. 1–2, 47–58 (2006).

M. P. Burka, V. F. Gorban’, A. N. Demidik, et al., “Mechanical properties of sintered titanium nanolaminates Ti3SiC2, Ti3AlC2, and Ti4AlN3 during indentation in temperature range 20–1200°C,” Metallofiz. Nov. Tech., 28, No. 6, 749–768 (2006).

S. A. Firstov, V. F. Gorban’, and E. P. Pechkovskii, “Strength and ductility of sintered composite ceramics based on ternary compounds—titanium nanolaminates,” in: Abstracts of 46th Int. Conf. on Important Problems of Strength (October 15–17, 2007, Vitebsk, Belarus) [in Russian], Part 2, Vitebsk State Technological University, Vitebsk (2007), pp. 9–14.

S. A. Firstov, V. F. Gorban’, I. I. Ivanova, and E. P. Pechkovskii, “Mechanical behavior of sintered porous two-phase titanium composite nanolaminatesat high temperatures,” Engin. Mat., 409, 300–303 (2009).

V. F. Gorban’, A. N. Demidik, I. I. Ivanova, et al., “The effect of phase composition and porosity of sintered two-phase titanium composite nanolaminateson deformation and strength characteristics,” in: Abstracts of 5-th Int. Conf. on Materials and Coatings in Extreme Conditions: Research, Application, Environmentally Sound Production Technologies, and Disposal of Products (September 22–26, 2008, Zhukovka, Crimea, Ukraine) [in Russian], Kiev (2008), p. 2.

I. I. Ivanova, A. N. Demidik, N. A. Krylova, et al., “Sintering characteristics and mechanical behavior of porous composites based on titanium nanolaminates,” in: Proc. Int. Conf. on Materials Science for Refractory Compounds: Achievements and Challenges (May 27–29, 2008, Kiev, Ukraine) [in Russian], Kiev (2008), p. 1.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Poroshkovaya Metallurgiya, Vol. 53, No. 7–8 (498), pp. 3–13, 2014.

Rights and permissions

About this article

Cite this article

Ivanova, I.I., Demidik, A.N., Karpets, M.V. et al. Synthesis of Binary Titanium Compounds TI3ALC2 and TI4ALN3 by Isothermal Sintering. Powder Metall Met Ceram 53, 377–385 (2014). https://doi.org/10.1007/s11106-014-9627-x

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11106-014-9627-x