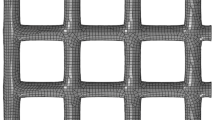

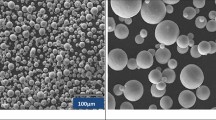

Additive manufacturing (AM) allows producing objects with functional internal structures; one of their applications is the production of medical implants (scaffolds), which may substitute bone tissue. The aim of this study is to evaluate, by micro computed tomography (μCT), the geometric accuracy of scaffolds manufactured from Ti–6Al–7Nb alloy by selective laser melting (SLM). Micro-CT is a non-destructive method for investigating internal object structures. Its application in analysis of bone scaffolds allowed obtaining full geometric characterization of manufactured structures as 3D models and evaluation of the conformance of the scaffolds to their CAD designs. The influence of building direction during production of the quality SLM structures was also examined. Scaffold characteristics important for the application in tissue engineering, such as porosity and the actual surface area, were obtained. Validation of the μCT method, by examining selected cross-sections with a scanning electron microscope (SEM), proved that differences in dimensional characteristics of structures did not exceed 10 micrometers.

Similar content being viewed by others

References

Chunze Yana and Liang Hao, “Evaluations of cellular lattice structures manufactured using selective laser melting,” Int.l J. Mach. Tool. Manuf., 62, 32–38 (2012).

T. Kurzynowski, E. Chlebus, B. Kuznicka, and B. Dybala, „SLM processing of metal powders,” in: The 7th International Conference on Manufacturing Research (ICMR09) University of Warwick, (September 8–10, UK), (2009).

E. Chlebus, B. Kuznicka, T. Kurzynowski, and B. Dybala, „Microstructure and mechanical behavior of Ti―6Al―7Nb alloy produced by selective laser melting,” Mater. Character., 6, No. 2, 488–495 (2011).

D. Wang, “Research on the fabricating quality optimization of the overhanging surface in SLM process,” Int. J. Adv. Manuf. Technol., 65, 1471–1484 (2013).

S. R. Stock, MicroComputed Tomography: Methodology and Application, CRC Press, Boca Raton, FL, USA 2009, p. 336.

Saey Tuan Hoa and Dietmar W. Hutmachea, “A comparison of micro CT with other techniques used in the characterization of scaffolds,” Biomaterials, 27, 1362–1376 (2006).

S. Van Bael and Y. C. Chai, “The effect of pore geometry on the in vitro biological behavior of human periosteum-derived cells seeded on selective laser-melted Ti6Al4V bone scaffolds,” Act. Biomat., 8, No. 7, 2824–2834 (2012).

S. Van Bael and G. Kerckhofs, “Micro-CT-based improvement of geometrical and mechanical controllability of selective laser melted Ti6Al4V porous structures,” Mater. Sci. Eng. A, 528, 7423–7431(2011).

Acknowledgements

The study was co-financed by the European Regional Development Fund, project: “Bio-implants for osseous tissue decrement in patients with cancer treatment” (Contract number POIG.01.01.02-00-022/09).

Author information

Authors and Affiliations

Corresponding author

Additional information

Published in Poroshkovaya Metallurgiya, Vol. 54, Nos. 3–4 (502), pp. 12–16, 2015.

Rights and permissions

About this article

Cite this article

Ziolkowski, G., Szymczyk, P., Dybala, B. et al. Geometric Characteristics of Scaffolds Made by Additive Manufacturing. Powder Metall Met Ceram 54, 136–139 (2015). https://doi.org/10.1007/s11106-015-9690-y

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11106-015-9690-y